Novel double-faced drying box for roll paper intaglio printing press

A web and gravure printing machine technology, which is applied in the double-sided drying box field of a new web gravure printing machine, can solve the problems of cumbersome operation, poor practical performance, and complex structure of the water cooling drum, and achieve simple operation and simple structure , good drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

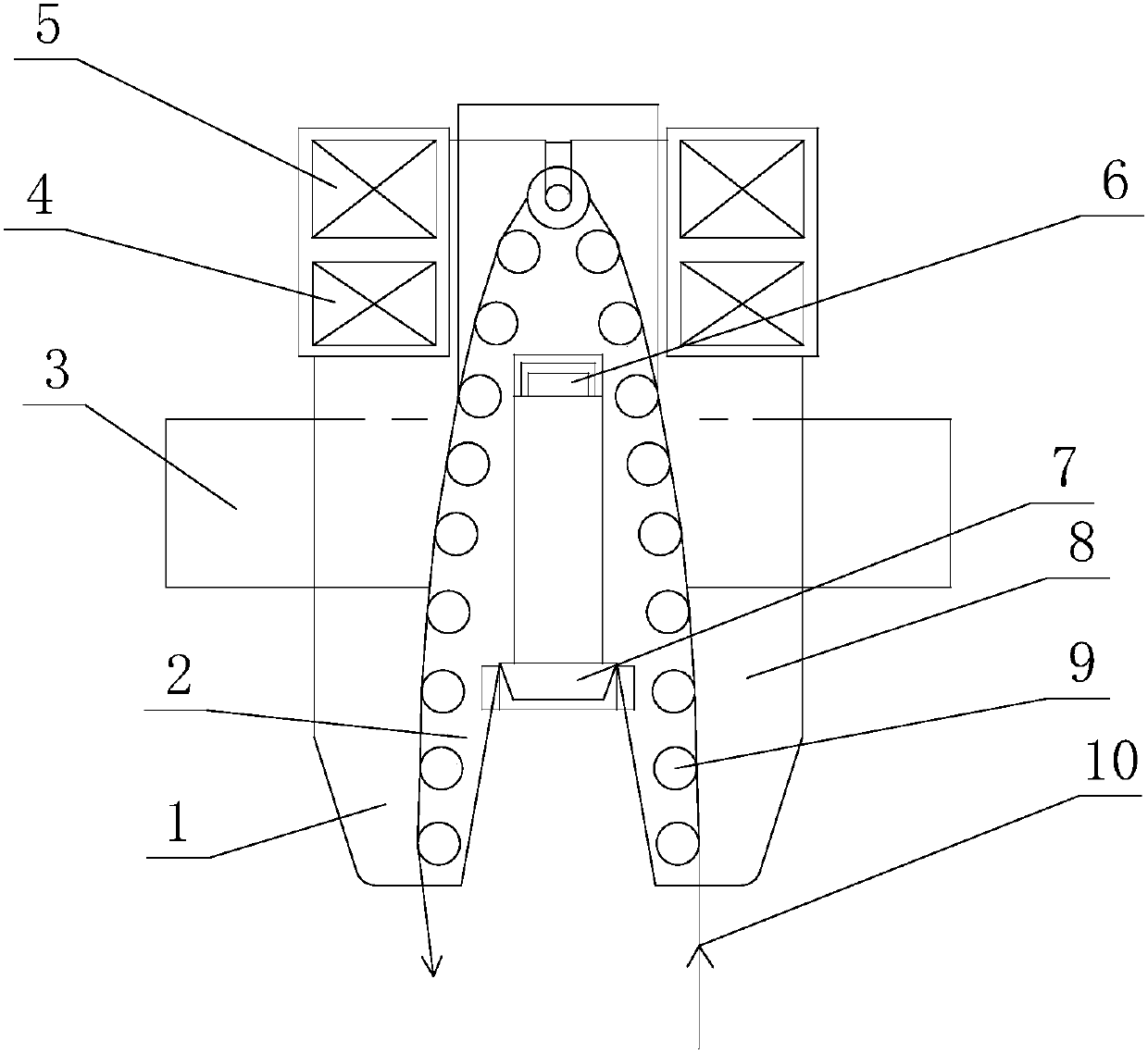

[0010] The present invention will be further described now in conjunction with accompanying drawing. These drawings are simplified schematic diagrams only to illustrate the basic structure of the present invention in a schematic way, so they only show the components relevant to the present invention.

[0011] Such as figure 1 The double-sided drying box of the new web gravure printing machine shown includes a middle wallboard 3, on which the upper and lower stays 6 and 7 distributed up and down are installed, and the upper and lower stays 6 and 7 are upper and lower. The middle box 2 is fixed, and there are only guide rollers 9 in the middle box 2; the left box 1 and the right box 8 are arranged on the left and right sides of the middle box 2, and the left box 1 and the right box 8 are respectively provided with an air inlet 4 and an air outlet 5 .

[0012] The left case 1 and the right case 8 are provided with a cylinder for adjusting the distance between the left case 1 an...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap