Expansion tank used by double systems of new energy automobile in common

A new energy vehicle, expansion tank technology, applied in the direction of vehicle components, component optimization, and the arrangement of the cooling combination of the power unit, can solve the problems of limited layout space of the engine compartment, high maintenance and maintenance costs, and unfavorable vehicle bodies, to simplify the first time. The effect of filling operation, convenient later maintenance and saving design quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings to facilitate a clearer understanding of the present invention, but the present invention is not limited to the following specific embodiments.

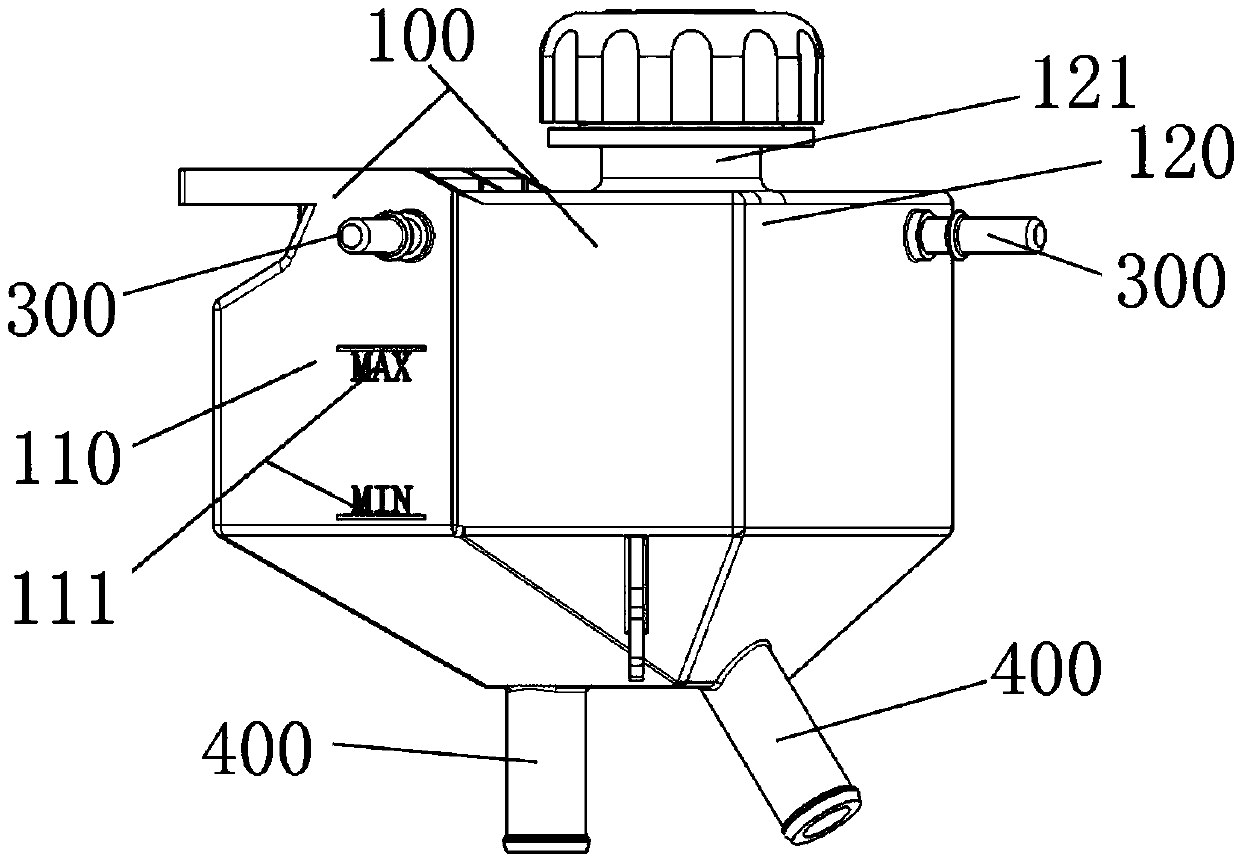

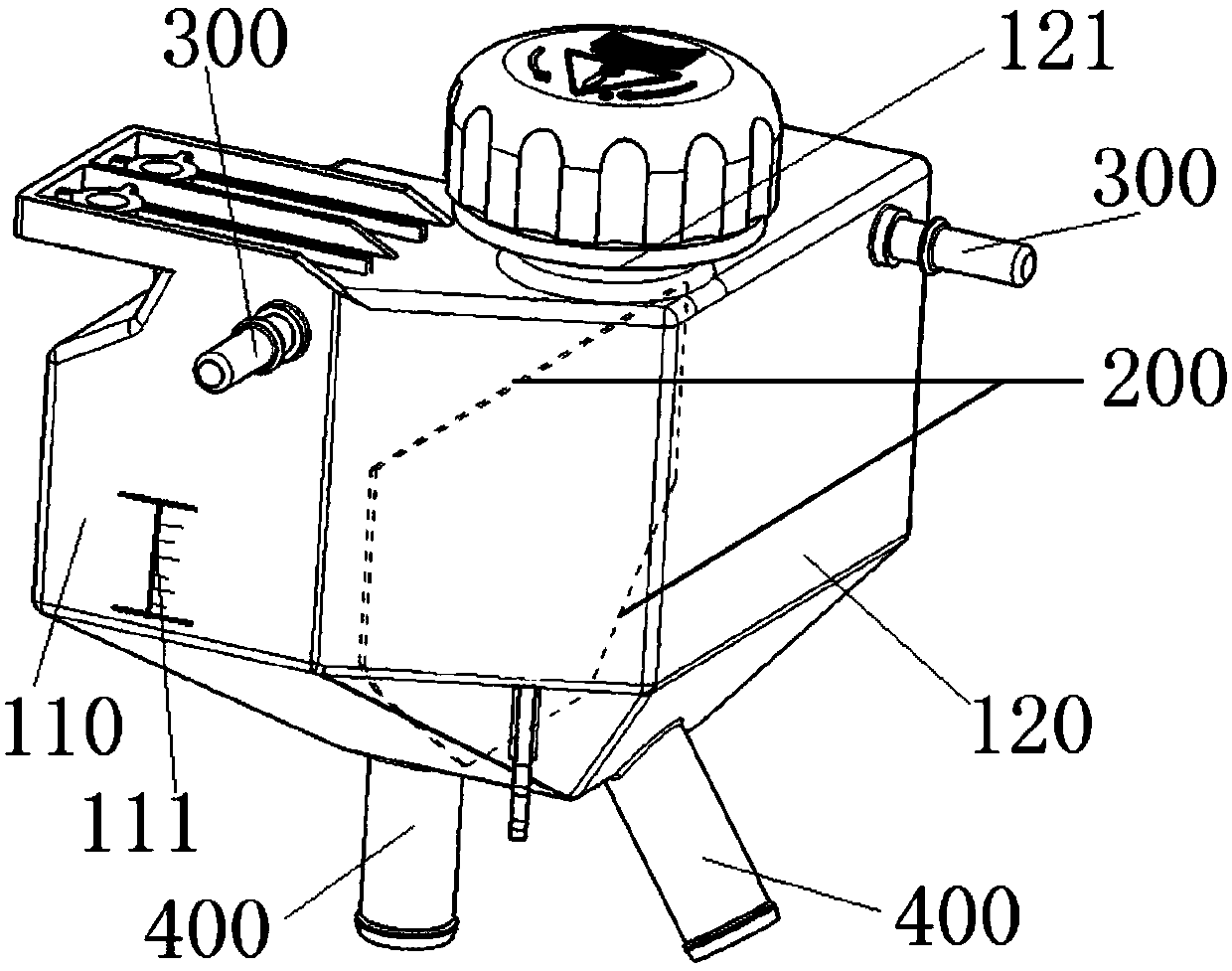

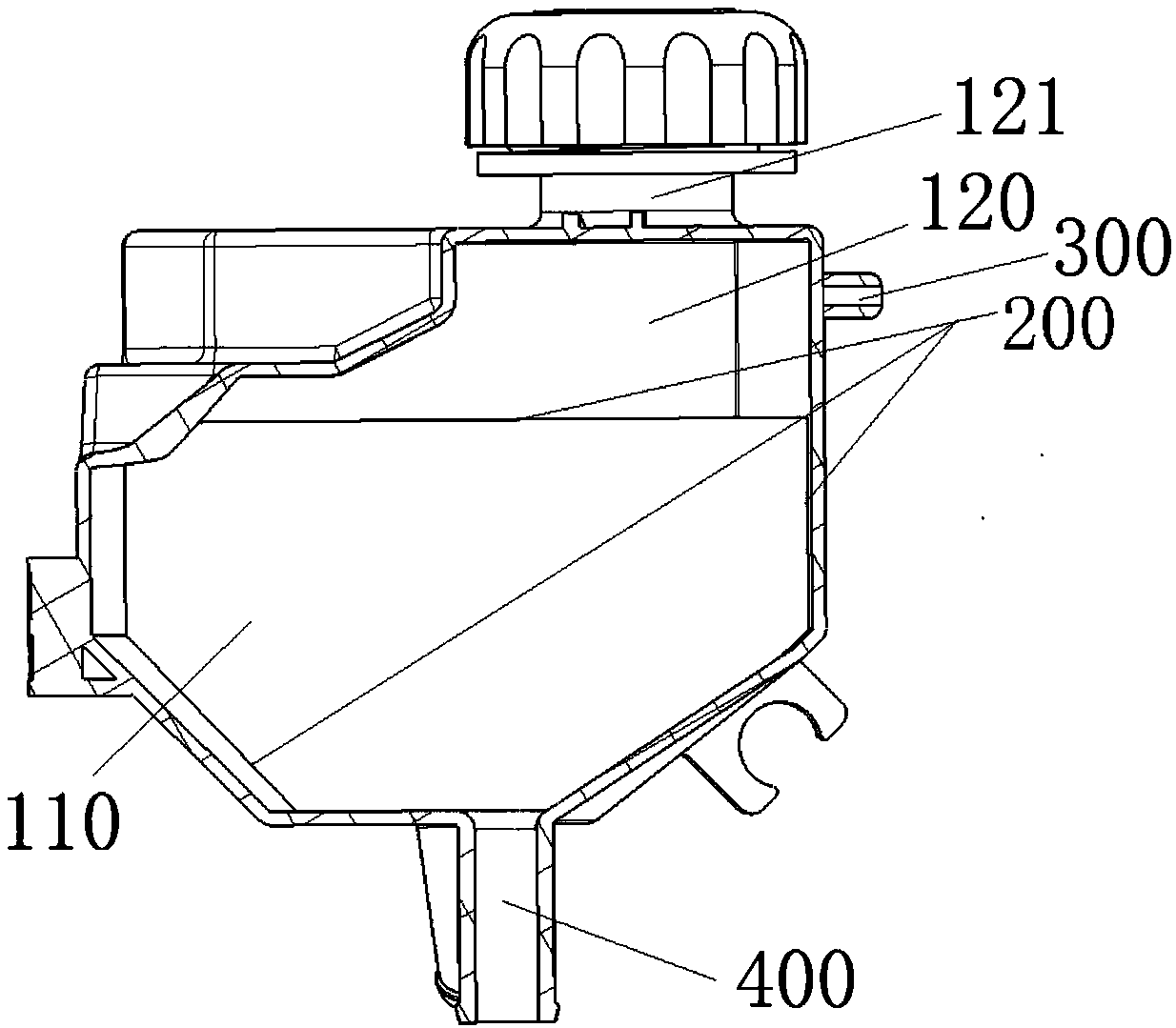

[0020] Such as figure 1 , figure 2 with image 3 As shown, a dual-system shared expansion water tank for a new energy vehicle of the present invention includes an expansion water tank 100 and a partition 200. The partition 200 is vertically arranged and divides the interior of the expansion tank 100 into two separate chambers connected with the upper part and the lower part respectively. It is a high temperature chamber 110 and a low temperature chamber 120. The high temperature chamber 110 communicates with the driving motor cooling system, and the low temperature chamber 120 communicates with the power battery cooling system; the bottom and two sides of the partition 200 are connected to the bottom and two sides of the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com