A kind of electrochemical water treatment equipment and water treatment method

A kind of water treatment equipment, electrochemical technology, applied in the direction of chemical instruments and methods, water/sewage treatment, neutralized water/sewage treatment, etc., can solve the problems of low current efficiency, high energy consumption, poor mass transfer effect, etc., and achieve reduction Energy consumption, enhanced micro-flow field, and strong water permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

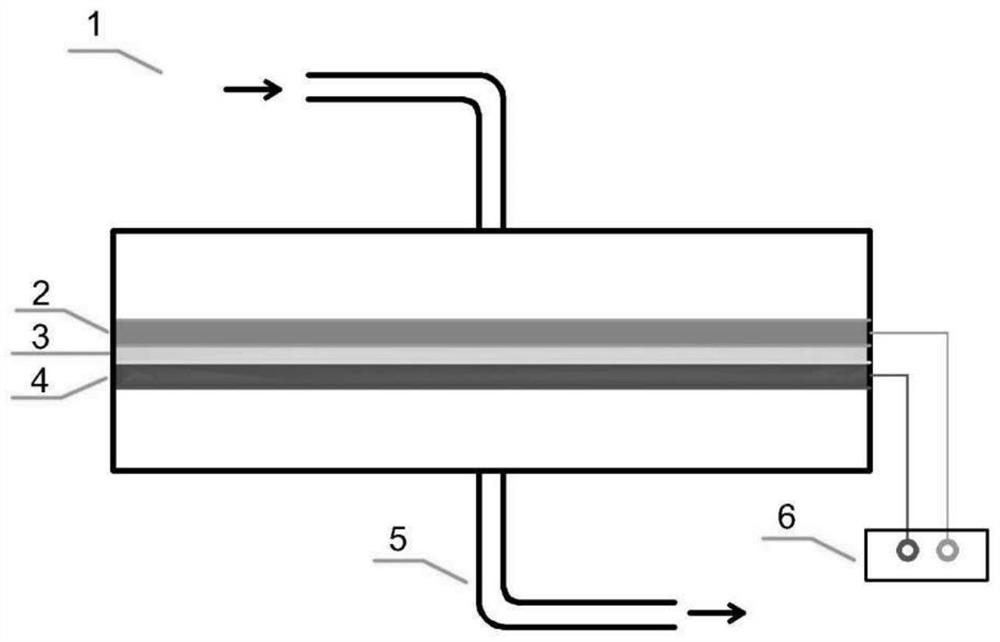

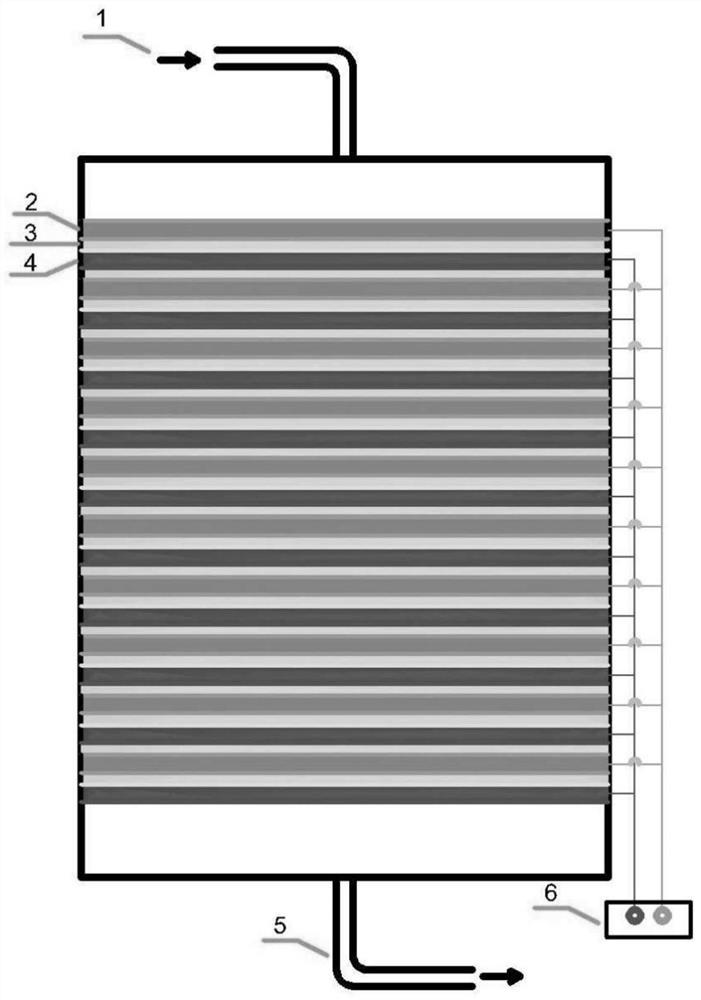

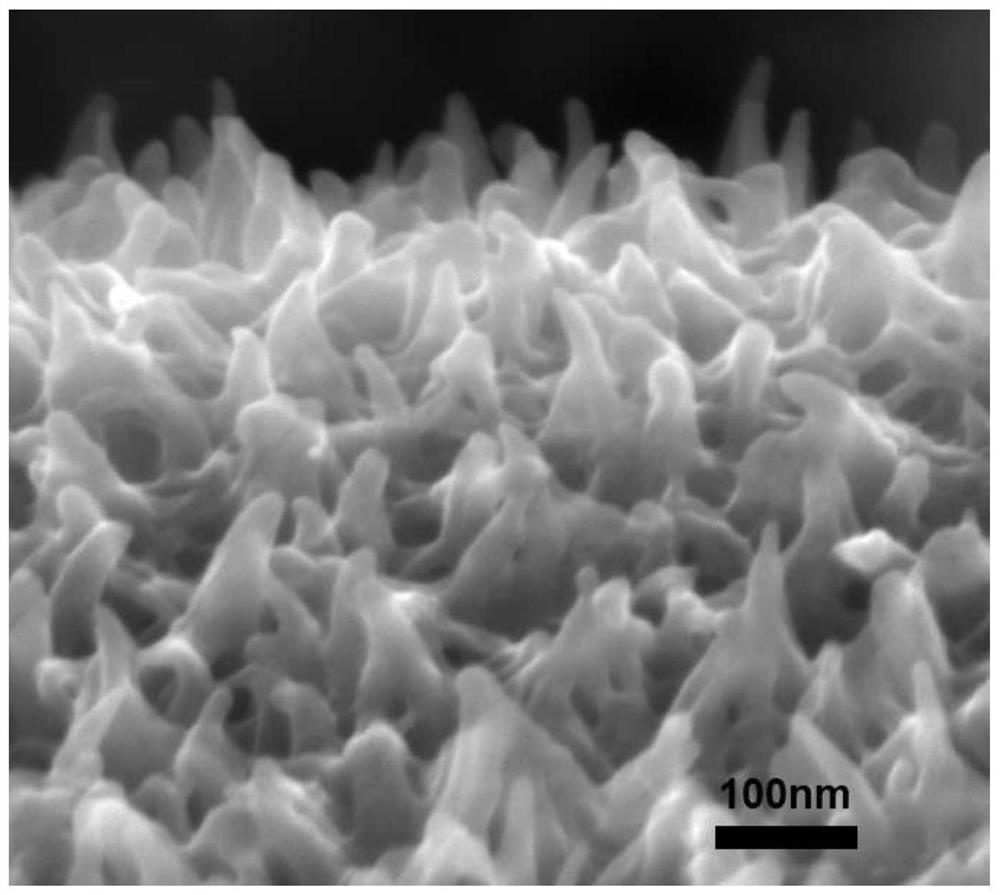

[0057] A through-type electrochemical water treatment device enhanced by a microflow field, consisting of an electrode with an ordered pore structure and an insulating isolation layer, wherein the cathode 2 is a three-dimensional graphene loaded with a polyaniline nanocone array, with a porosity of 80%. The pore diameter is 0.4 μm, the thickness is 0.4mm, and the nanocone height is 100-150nm, and the average width is 30-60nm, which are randomly and densely distributed on the pore wall of the pore structure of the cathode 2; the anode 4 is graphene, the porosity is 90%, and the pore diameter is 0.5 μm and a thickness of 0.4 mm; the insulating layer 3 is porous cellulose acetate with a porosity of 70%, a pore diameter of 0.8 μm and a thickness of 0.1 mm.

[0058] Use the through-type electrochemical water treatment equipment strengthened by the micro flow field for water treatment, apply a voltage to the cathode and anode 2 and 4, the voltage is 1.5V, and then adjust the pH of th...

Embodiment 2

[0060] A through-type electrochemical water treatment device enhanced by a microflow field, consisting of an electrode with an ordered pore structure and an insulating isolation layer, wherein the cathode 2 is a three-dimensional graphene loaded with a polyaniline nanocone array, with a porosity of 80%. The pore diameter is 0.4 μm, the thickness is 0.4mm, and the nanocone height is 100-200nm, and the average width is 30-60nm, which are randomly and densely distributed on the pore wall of the pore structure of the cathode 2; the anode 4 is graphene, the porosity is 90%, and the pore diameter is 0.5 μm and a thickness of 0.4 mm; the insulating layer 3 is porous cellulose acetate with a porosity of 70%, a pore diameter of 0.8 μm and a thickness of 0.1 mm.

[0061] Use the through-type electrochemical water treatment equipment strengthened by the micro flow field for water treatment, apply a voltage to the cathode and anode 2, 4, the voltage is 1.5V, then adjust the pH of the raw w...

Embodiment 3

[0063] A kind of through-type electrochemical water treatment equipment enhanced by micro flow field, which is composed of electrodes with ordered pore structure and insulating isolation layer, wherein the cathode 2 is three-dimensional graphene loaded with palladium nanoparticles, the porosity is 85%, and the pore diameter is 0.45μm, thickness 0.4mm, palladium nanoparticles particle size 10-30nm, loading rate 5-10%, uniformly distributed on the pore wall of the pore structure of cathode 2; anode 4 is graphene, porosity 90%, pore diameter is 0.5 μm, and has a thickness of 0.4 mm; the insulating layer 3 is porous acetate with a porosity of 70%, a pore diameter of 0.8 μm, and a thickness of 0.1 mm.

[0064] Use the through-type electrochemical water treatment equipment strengthened by the micro-flow field to carry out water treatment, apply a voltage to the cathode and anode 2, 4, and the voltage is 1.5V, and then adjust the pH of the raw water containing 100ug / L of trichloroacet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com