Natural stirring and mixing device and high-density sedimentation tank

A high-density sedimentation tank, stirring and mixing technology, which is applied in the field of sewage treatment equipment, natural stirring and mixing devices and high-density sedimentation tanks, can solve the problems of inconvenient construction and installation, power consumption, and large maintenance, and achieve short construction period, The effect of saving electric energy and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

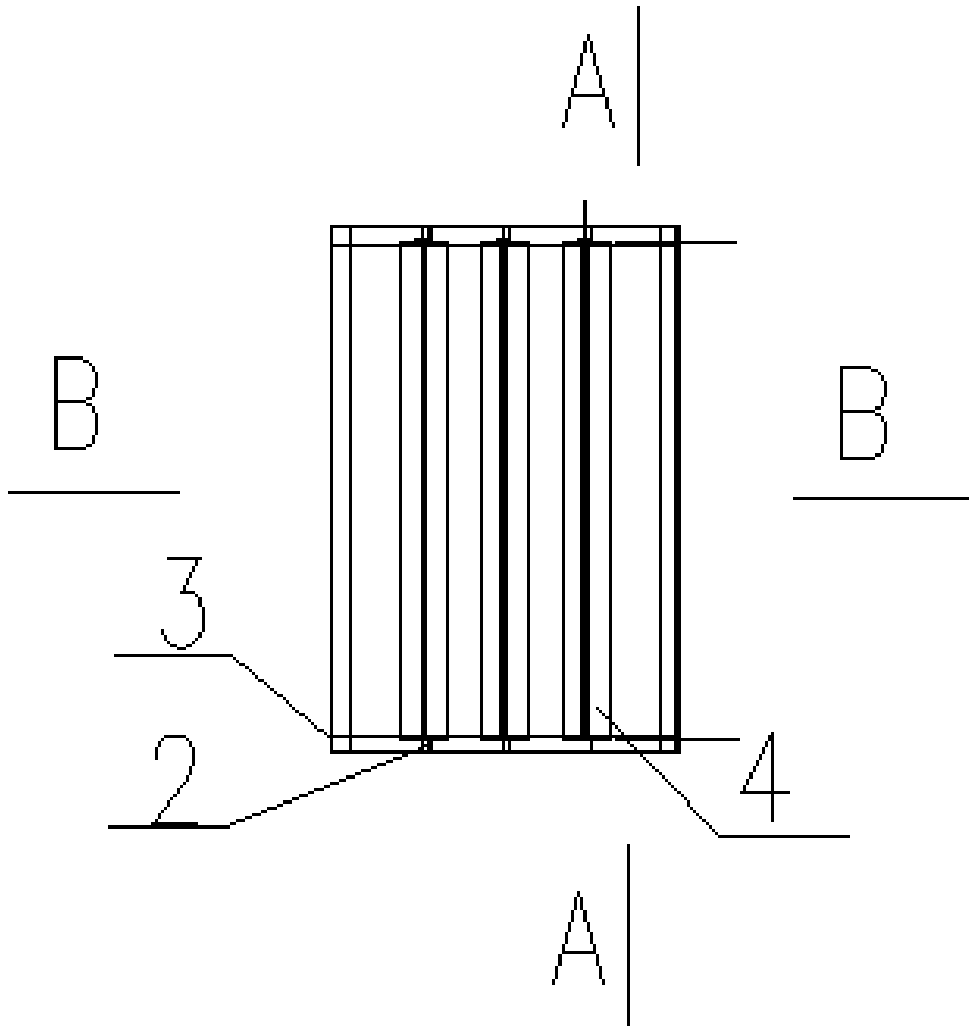

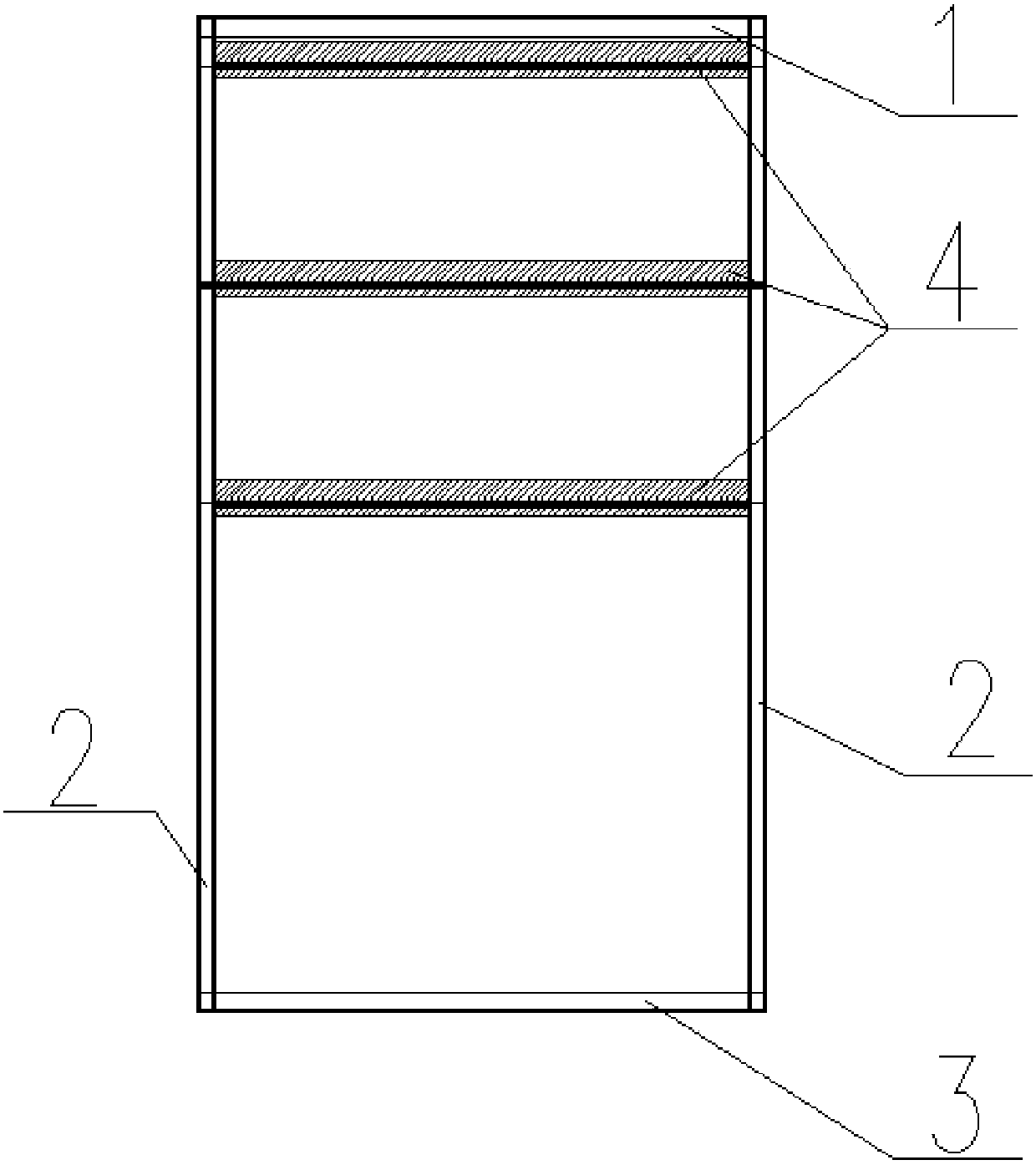

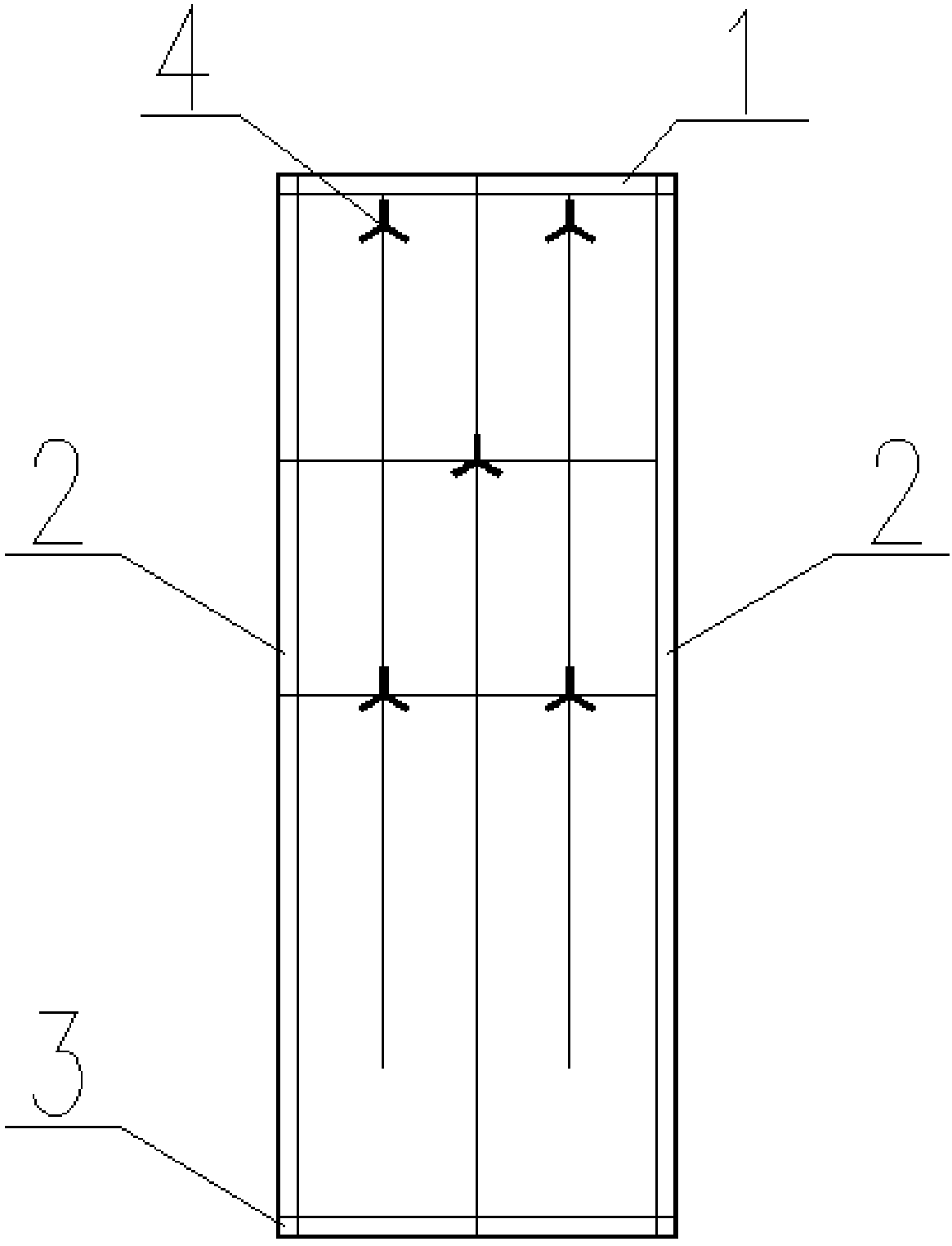

[0041] Such as figure 1 - Figure 4 As shown, the present embodiment provides a natural stirring mixing device, including a frame and a flocculation fin 4 arranged in the frame;

[0042] Sickle fins 6 are arranged on the floc fins 4 .

[0043] Most of the coagulation tanks in traditional high-density sedimentation tanks are equipped with agitators or mixers for mixing by means of mechanical agitation, which not only requires high equipment, troublesome construction and installation, but also requires frequent maintenance, high maintenance costs, time-consuming and laborious, and increases Reduced production costs and reduced production efficiency. In view of this, the present invention provides a natural agitation high-efficiency mixing device through hydraulic mixing, in which sewage and medicament / coagulant are mixed efficiently and fully. Hydraulic mixing is used instead of mechanical mixing, which reduces mechanical investment and has a very low failure rate. It can not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com