Soft coal step-by-step zooming hydraulic fracturing anatonosis device and method

A hydraulic fracturing and soft coal technology, applied in safety devices, earthwork drilling, gas discharge, etc., can solve problems such as long fracturing construction time, increased cost and difficulty of gas treatment, coal extrusion, etc., to achieve good economic and social benefits, effective control of gas disasters, and effective fracturing of coal and rock mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

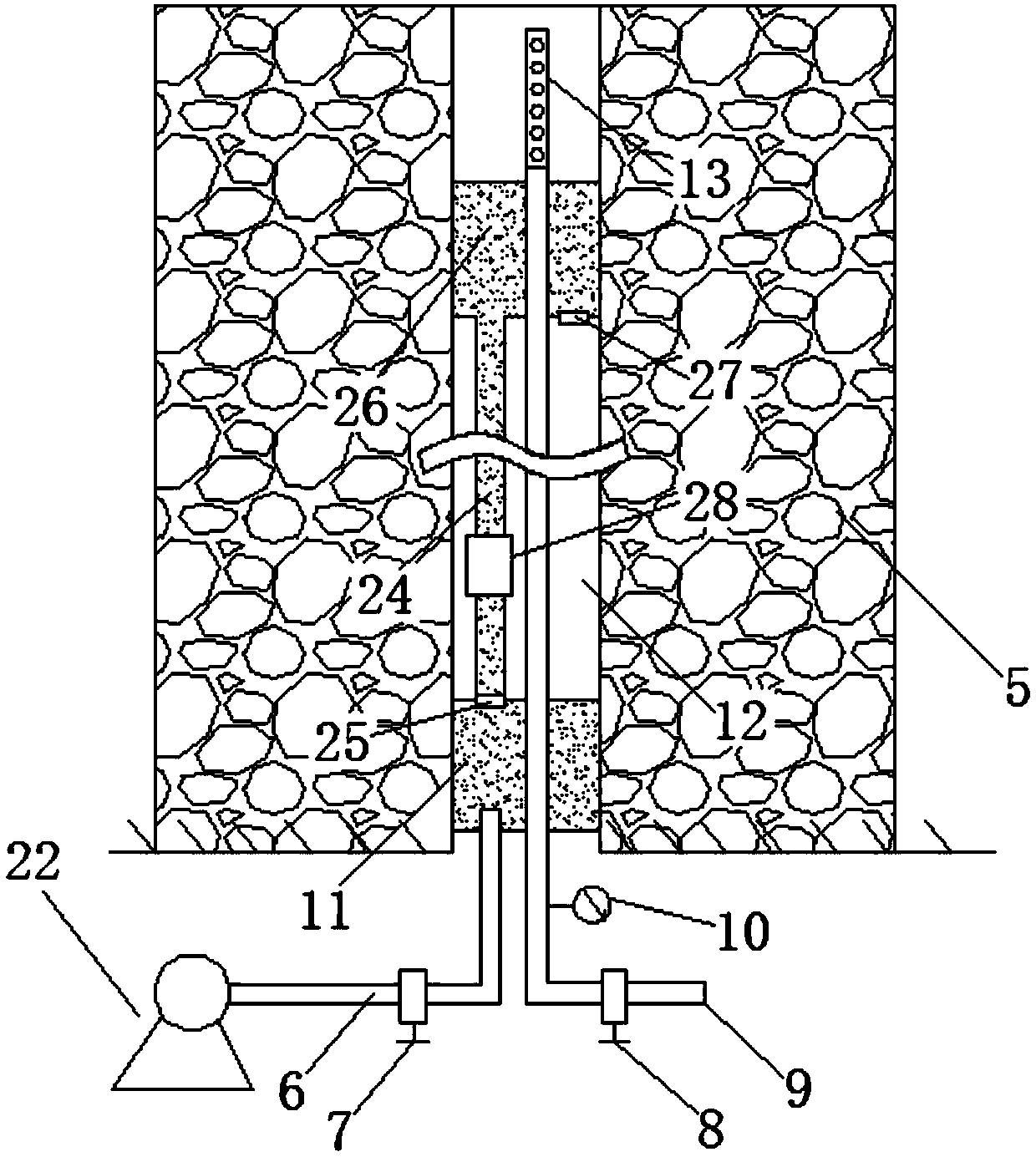

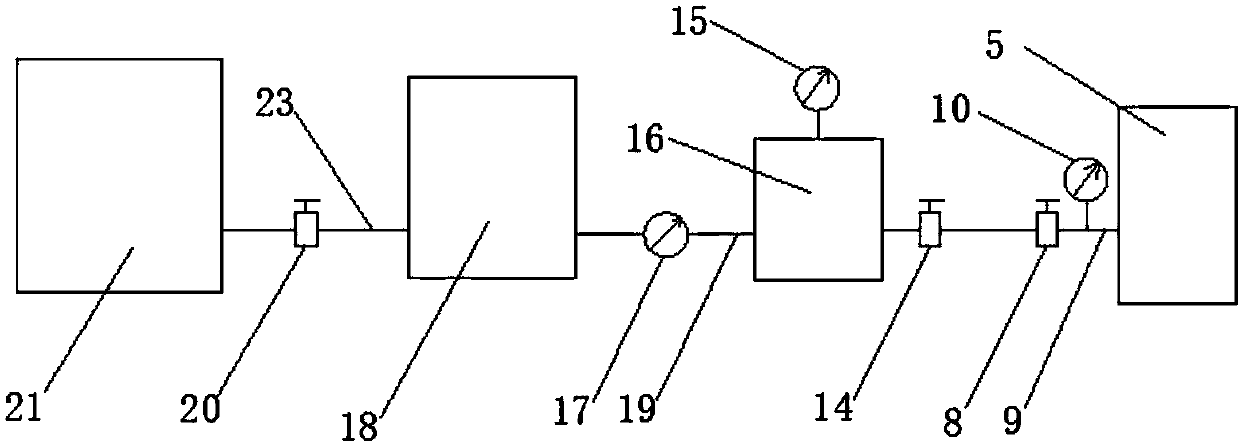

[0029] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

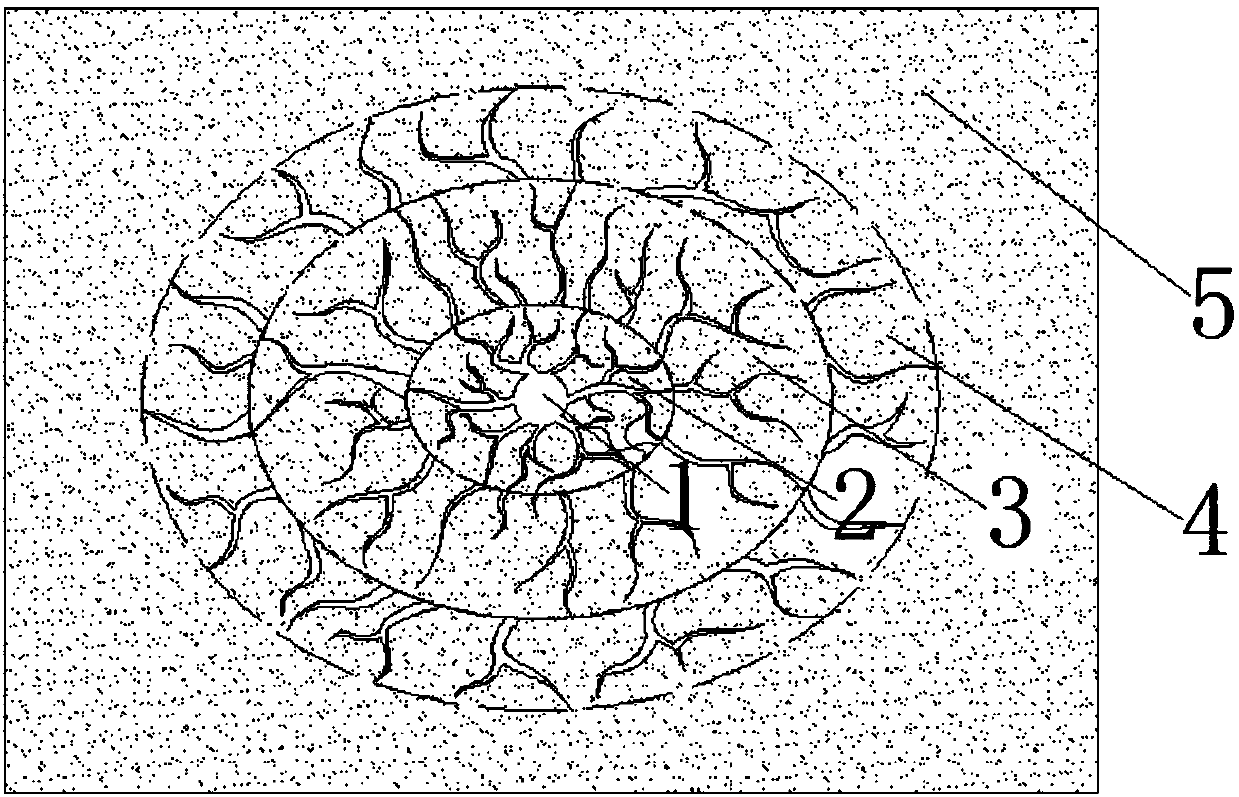

[0030] figure 1 It is a schematic diagram of step-by-step fracturing of gas drainage boreholes of the present invention, such as figure 1 Shown, the present invention comprises the steps:

[0031] 1. Accurately identify and divide underground geological structures based on the theory of transparent space physics, and accurately grasp the distribution of geological structures. Combining with modern testing technology, determine the coal seam joints, the development of pores and fissures, and the strength of the coal body. On this basis, the gas drainage fracturing drilling 1 is scientifically arranged.

[0032] 2. Efficient sealing of gas drainage fracturing borehole 1;

[0033] 3. Carry out step-by-step hydraulic fracturing to the gas drainage fracturing borehole 1 .

[0034] In step 1, when arranging gas drainage fracturing drilling 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com