Fuel gas air volume distributing joint control assembly for commercial cooking range

A stove and gas technology, which is applied in the field of gas air volume distribution joint control assembly, can solve the problems of large gas volume, and achieve the effects of avoiding environmental pollution, efficient use of energy, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

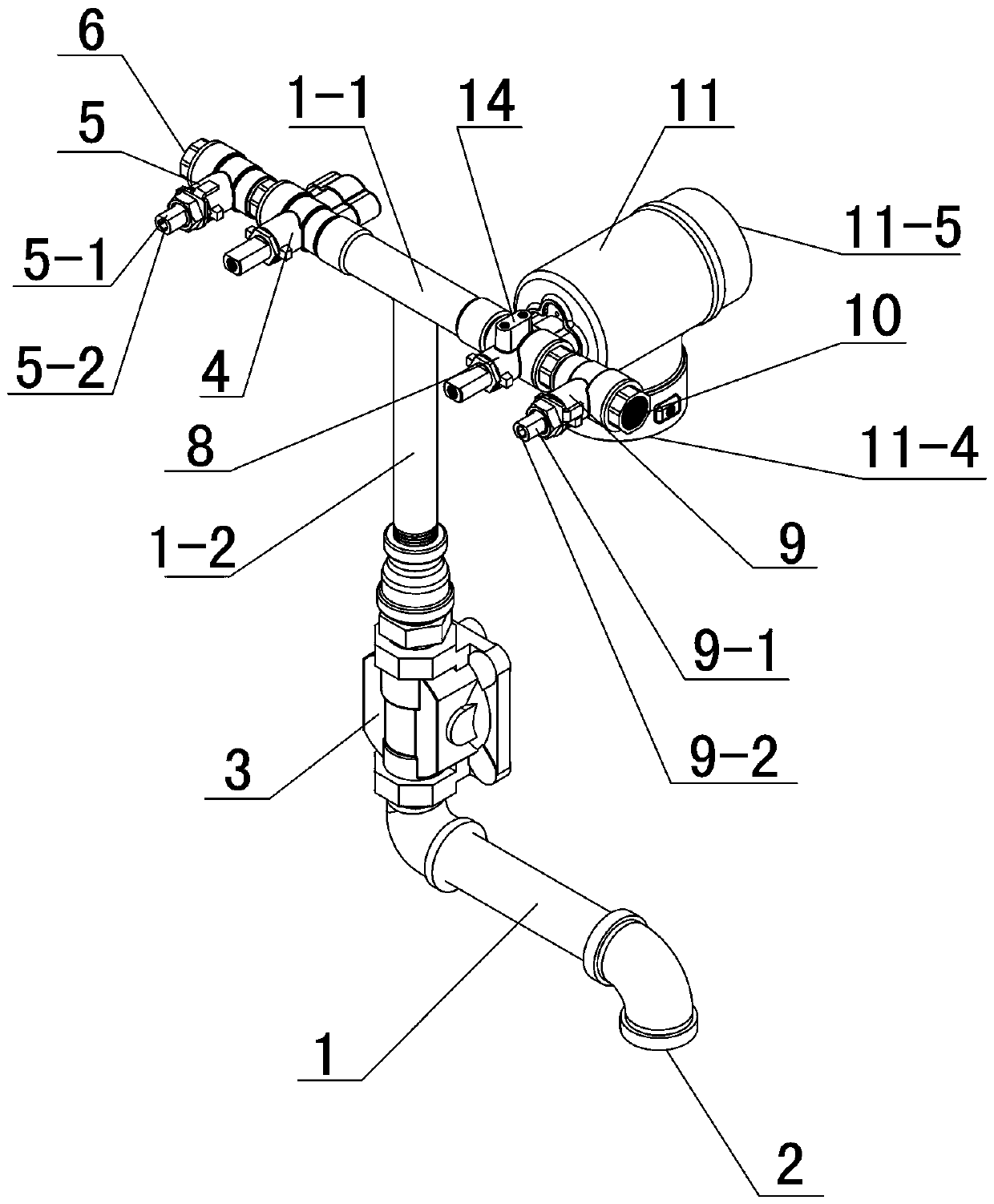

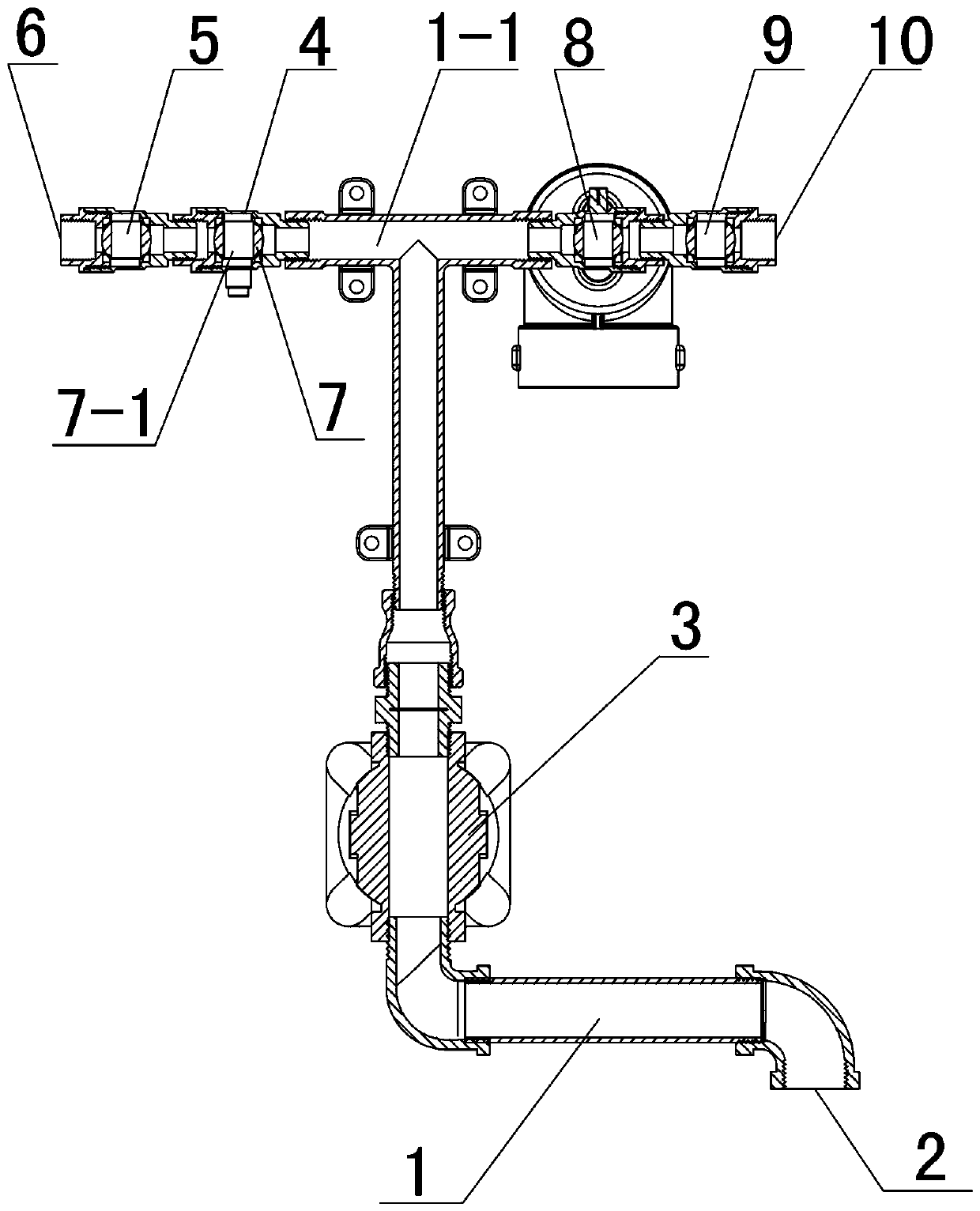

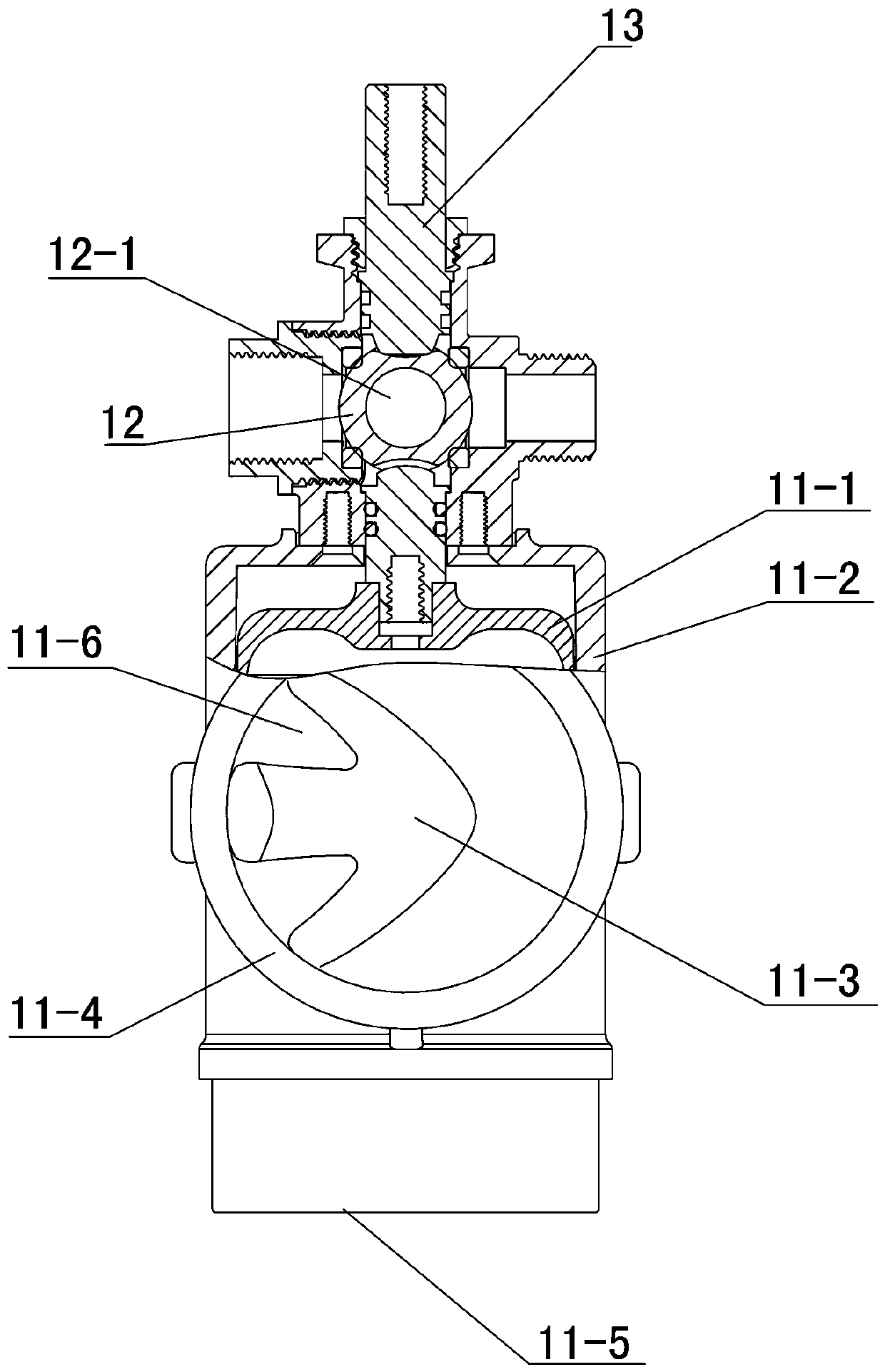

[0032] When using the stove for the first time, first use the hexagonal wrench to adjust the gas flow of the kindling gas limiting valve 5 and the main fire limiting valve 9, so that the gas flow in circulation can meet the needs of daily use. Then open the kindling ignition valve 4, the gas enters from the air inlet 2 and flows through the pressure stabilizing valve 3, the kindling ignition valve 4, the kindling gas limiting valve 5 successively, and flows out from the kindling gas outlet 6 to reach the burner. The air enters from the air cylinder inlet cylinder 11-4, enters the air cylinder inner cylinder 11-1 through the gap between the two horns 11-6 and the crescent hole 11-7, and then flows out from the air outlet 11-5 When it reaches the burner head, the gas and air are mixed and burned at the burner head to realize the ignition of an open flame.

[0033] When it is necessary to increase the firepower, turn the handle, and the handle will drive the linkage valve adjustm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com