An automatic simulation system for deformable cave filling

A simulation system and karst cave technology, which is applied in general control systems, control/regulation systems, instruments, etc., can solve the problems of lack of filling-type karst cave simulation experimental devices, and achieve energy saving, high analysis accuracy, and strong controllability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

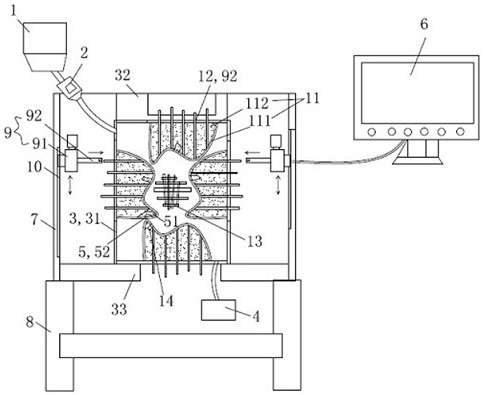

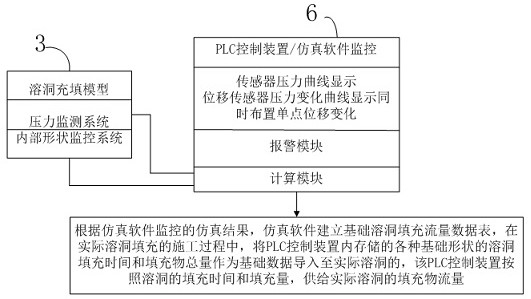

[0017] An automatic simulation system for deformable cave filling, such as figure 1 As shown, it includes a karst cave filling and watering device 1, a watering and filling metering device 2, a karst cave filling model 3 and a bottom mouth metering device 4 connected in sequence, wherein: the karst cave filling model 3 is provided with a pressure monitoring system 5 and a monitoring camera 14, and the watering and filling The metering device 2, the bottom metering device 4 and the bottom metering device 4 are all connected to the PLC control device 6;

[0018] The pressure monitoring system 5 and the monitoring camera 14 are connected to the PLC control device 6 through a number of pressure sensors 51 and displacement sensors 52 distributed in the cave filling model 3; and the PLC control device 6 includes a display module, an alarm module and a calculation module. The calculation module Obtain the pressure value of each pressure sensor, the flow rate of the watering and filli...

Embodiment 2

[0025] The polymorphic cave filling simulation method includes the following steps:

[0026] A. Establish a karst cave model that can be deformed arbitrarily, and set the relevant filler injection port and bottom water port on the karst cave model, and then connect the karst cave pouring port metering device and the bottom port metering device;

[0027] B. Arrange the simulation model of the karst cave, set up a pressure monitoring system and an internal shape monitoring system in the karst cave simulation model, and place pressure sensors and displacement sensors at the relevant inflection points and pressure points of the karst cave. The pressure point can be the location where the stress is concentrated in the cave, and these pressure sensors are connected to the PLC control device; in the specific operation, the inflection point and the pressure point can also be set in the same position, which is convenient for control and placement;

[0028] C. Establish simulation softwar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com