Mixed bonding method having metal wire, and mixed bonding structure

A metal connection and hybrid bond technology, which is applied in the field of hybrid bonding structure, can solve the problems of increasing process cost, use, and inability to metal connection, and achieves the effect of reducing the bonding metal layer and reducing the process cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

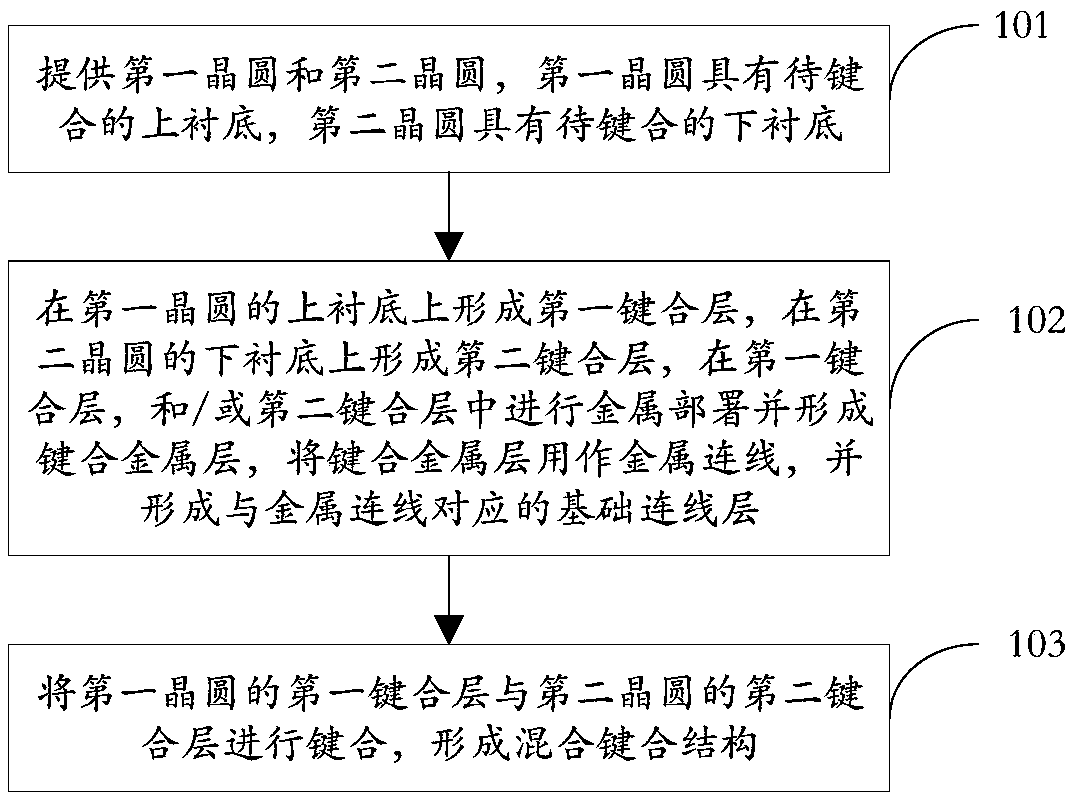

[0040] According to an embodiment of the present invention, a hybrid bonding method with metal wiring is provided, such as figure 1 shown, including:

[0041] providing a first wafer and a second wafer, the first wafer has an upper substrate to be bonded, and the second wafer has a lower substrate to be bonded;

[0042] Forming a first bonding layer on the upper substrate of the first wafer, forming a second bonding layer on the lower substrate of the second wafer, in the first bonding layer, and / or in the second bonding layer Performing metal deployment and forming a bonding metal layer, using the bonding metal layer as a metal connection, and forming a basic connection layer corresponding to the metal connection;

[0043] The first bonding layer of the first wafer is bonded to the second bonding layer of the second wafer to form a hybrid bonding structure.

[0044] According to an embodiment of the present invention, both the first bonding layer and the second bonding laye...

Embodiment approach

[0051] According to an embodiment of the present invention, the method further includes: forming a basic wiring layer corresponding to the switch metal layer;

[0052] Correspondingly, in the hybrid bonding structure formed by bonding, the switch metal layer is connected to the bonding metal contact and the corresponding basic wiring layer.

[0053] According to an embodiment of the present invention, forming a basic wiring layer corresponding to the metal wiring, specifically: forming a connection structure and a basic wiring layer corresponding to the metal wiring;

[0054] Correspondingly, in the hybrid bonding structure formed by bonding, the metal wiring is connected to the corresponding basic wiring layer through the connecting structure.

[0055] According to the embodiment of the present invention, it also includes: performing redundant filling (Dummy Filling) on the metal connection;

[0056] Further, the difference between the metal density of the redundant filled...

Embodiment 2

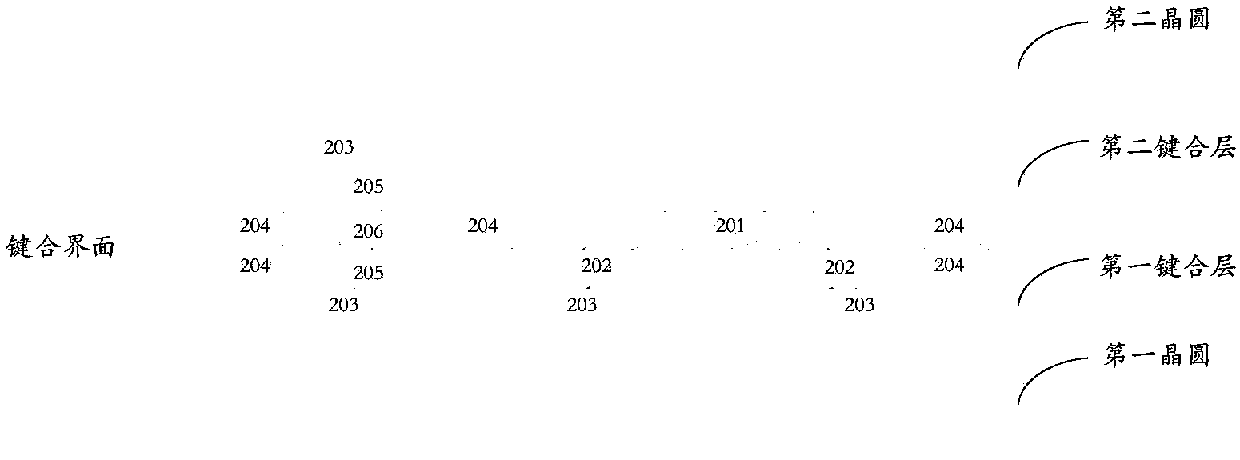

[0060] According to an embodiment of the present invention, a hybrid bonding structure with metal wiring is provided, including:

[0061] A first wafer and a second wafer arranged oppositely, the first wafer has an upper substrate for bonding, and the second wafer has a lower substrate for bonding;

[0062] a first bonding layer on the upper substrate of the first wafer, a second bonding layer on the lower substrate of the second wafer;

[0063] The metal arrangement located in the first bonding layer and / or the second bonding layer, the bonding metal layer as the metal wiring, and the basic wiring layer corresponding to the metal wiring.

[0064] According to an embodiment of the present invention, the metal layout located in the first bonding layer and / or in the second bonding layer specifically includes:

[0065] a plurality of metal blocks located in the first bonding layer, and / or in the second bonding layer;

[0066] a switch metal layer located in the first bonding la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com