Electrolyte and lithium metal battery

An electrolyte and lithium salt technology, applied in the field of electrolytes and lithium metal batteries, can solve the problems of lithium metal batteries such as low cycle performance and safety performance, poor mechanical properties, low conductivity, etc., achieve high mechanical modulus blocking, reduce flow properties, and the effect of improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention has no special restrictions on the preparation method of the electrolyte, and preferably includes the following steps: mixing the modified inorganic oxide particles, crosslinking agent, lithium salt, and non-aqueous solvent to obtain an electrolyte. Specifically, it is preferable to mix the lithium salt and the non-aqueous solvent uniformly to obtain a mixed solution; then, add the modified inorganic oxide particles to the mixed solution, and then add a crosslinking agent, and mix well to obtain an electrolyte.

[0034] Before the mixing of the lithium salt and the non-aqueous solvent, the present invention preferably further includes: removing water from the non-aqueous solvent. Specifically, it is preferable to remove water from the non-aqueous solvent with a dried molecular sieve.

[0035] After the removal of water, it preferably further includes: standing the non-aqueous solvent after removal of water.

[0036] The resting time is preferably 12 to 3...

Embodiment 1

[0051] First, use the dried molecular sieve to remove water from propylene carbonate (PC) and let it stand for 24 hours;

[0052] Silane modified aluminum oxide particles (AEROXIDE Alu805, Evonik Degussa Corporation, USA) dried at 130°C for 13h;

[0053] Weigh LiTFSI and PC with a mass ratio of LiTFSI:PC=3:7, mix them evenly to obtain a mixed solution; then, add the silane-modified aluminum oxide particles to the mixed solution, and then add the crosslinking agent polyacrylonitrile , After mixing, get electrolyte. Wherein, the mass of the silane-modified aluminum oxide particles accounts for 0.1% of the total mass of the LiTFSI and PC. The mass of the crosslinking agent polyacrylonitrile accounts for 3% of the total mass of the LiTFSI and PC.

[0054] Lithium sheets are used as positive and negative electrodes, respectively, and assembled with the above electrolyte and pp separator to form a lithium metal battery.

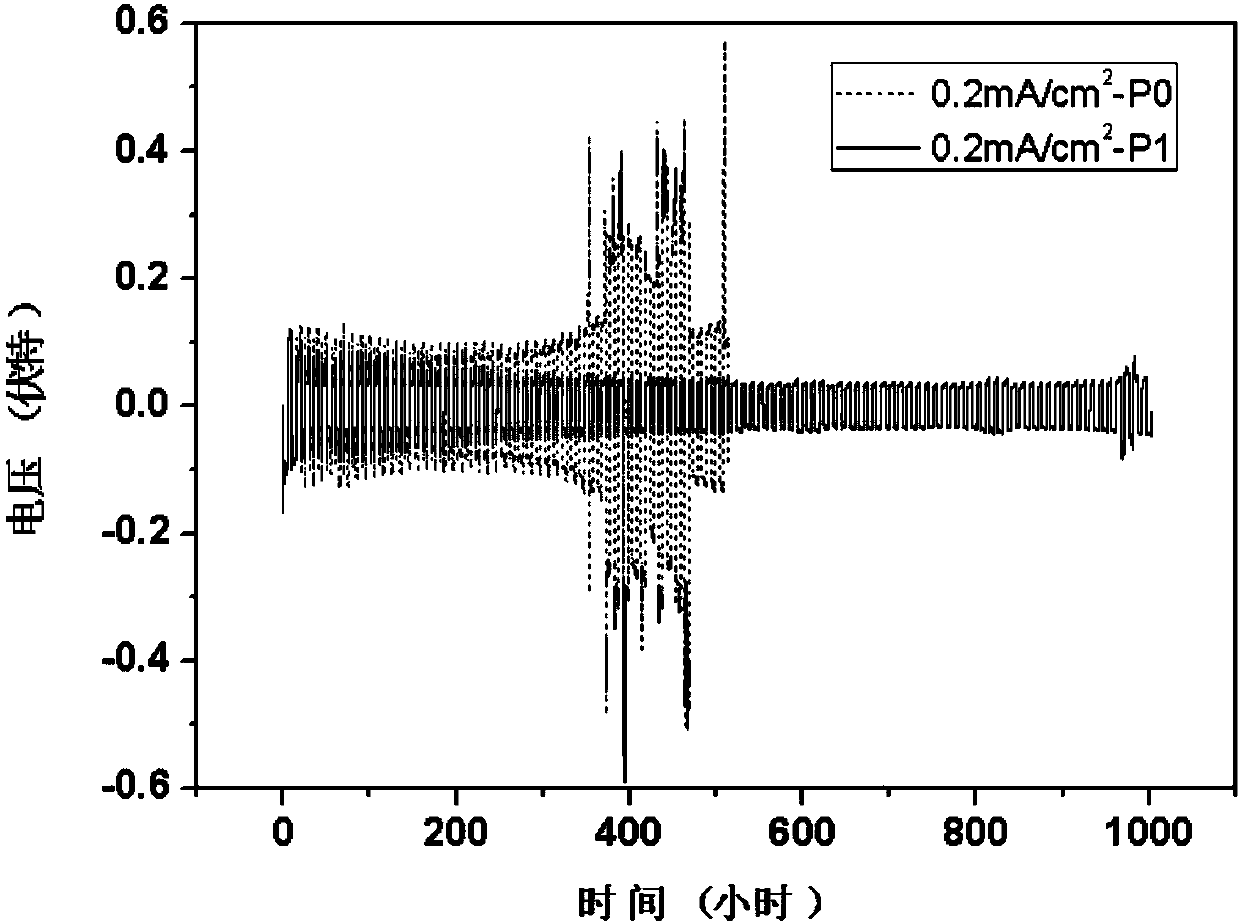

[0055] The lithium metal battery obtained above was subjected to l...

Embodiment 2

[0057] First, use the dried molecular sieve to remove water from propylene carbonate (PC) and let it stand for 24 hours;

[0058] Silane-modified aluminum oxide particles (AEROXIDE Alu805, Evonik Degussa Corporation, USA) dried at 130°C for 13h;

[0059] Weigh LiTFSI and PC with a mass ratio of LiTFSI:PC=3:7, mix them evenly to obtain a mixed solution; then, add the silane-modified aluminum oxide particles to the mixed solution, and then add the crosslinking agent polyacrylonitrile , After mixing, get electrolyte. Wherein, the mass of the silane-modified aluminum oxide particles accounts for 1% of the total mass of the LiTFSI and PC; the mass of the crosslinking agent polyacrylonitrile accounts for 5% of the total mass of the LiTFSI and PC.

[0060] Lithium sheets are used as positive and negative electrodes, respectively, and assembled with the electrolyte and pp separator to form a lithium metal battery.

[0061] The lithium metal battery obtained above was subjected to lithium-li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

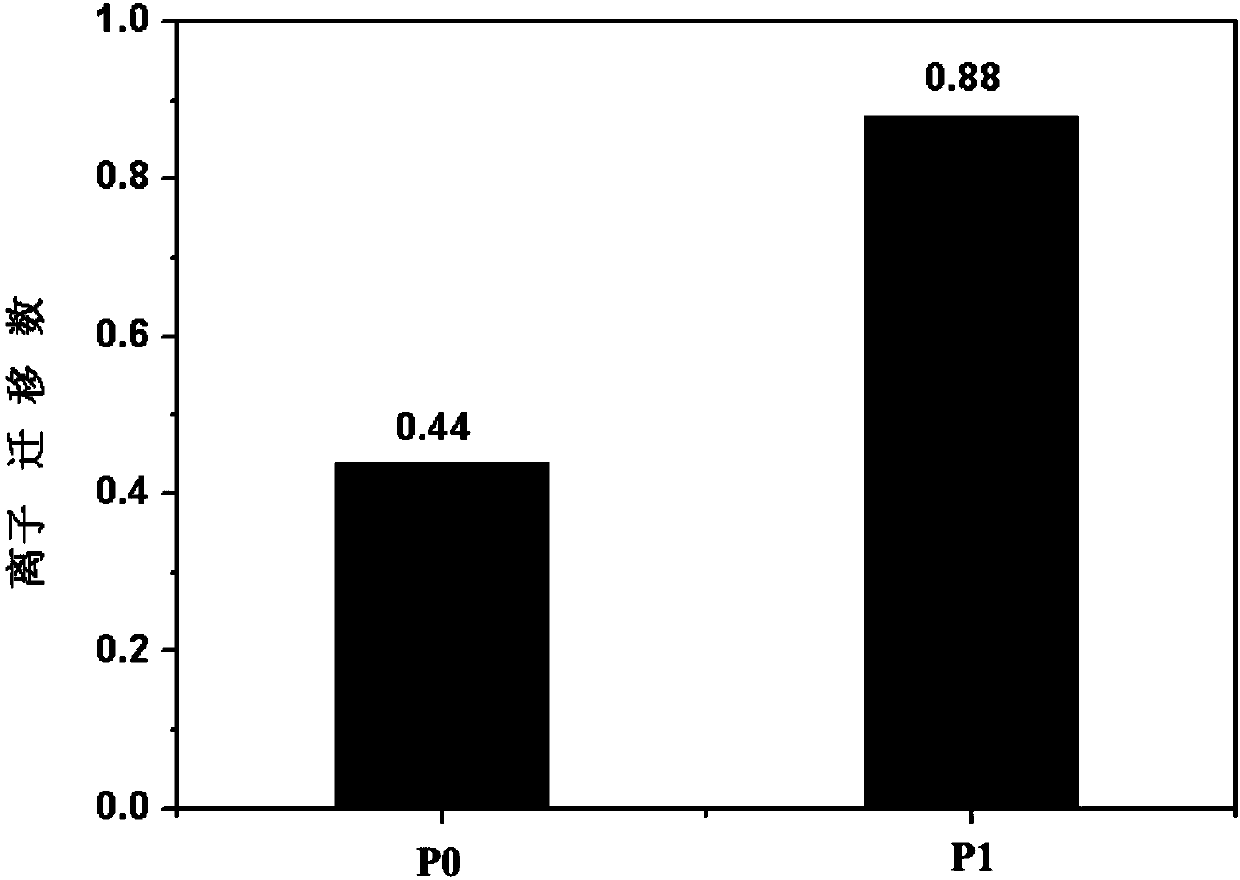

| transference number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com