Biomass circulating-fluidized-bed gasification device

A technology of circulating fluidized bed and fluidized bed gasifier, which is applied in gasification process, granular/powder fuel gasification, manufacture of combustible gas, etc., can solve the problem of lack of fly ash adsorption, alkali metal slagging tar corrosion, Blockage and other problems to achieve the effect of reducing condensation corrosion, reducing slagging, and improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

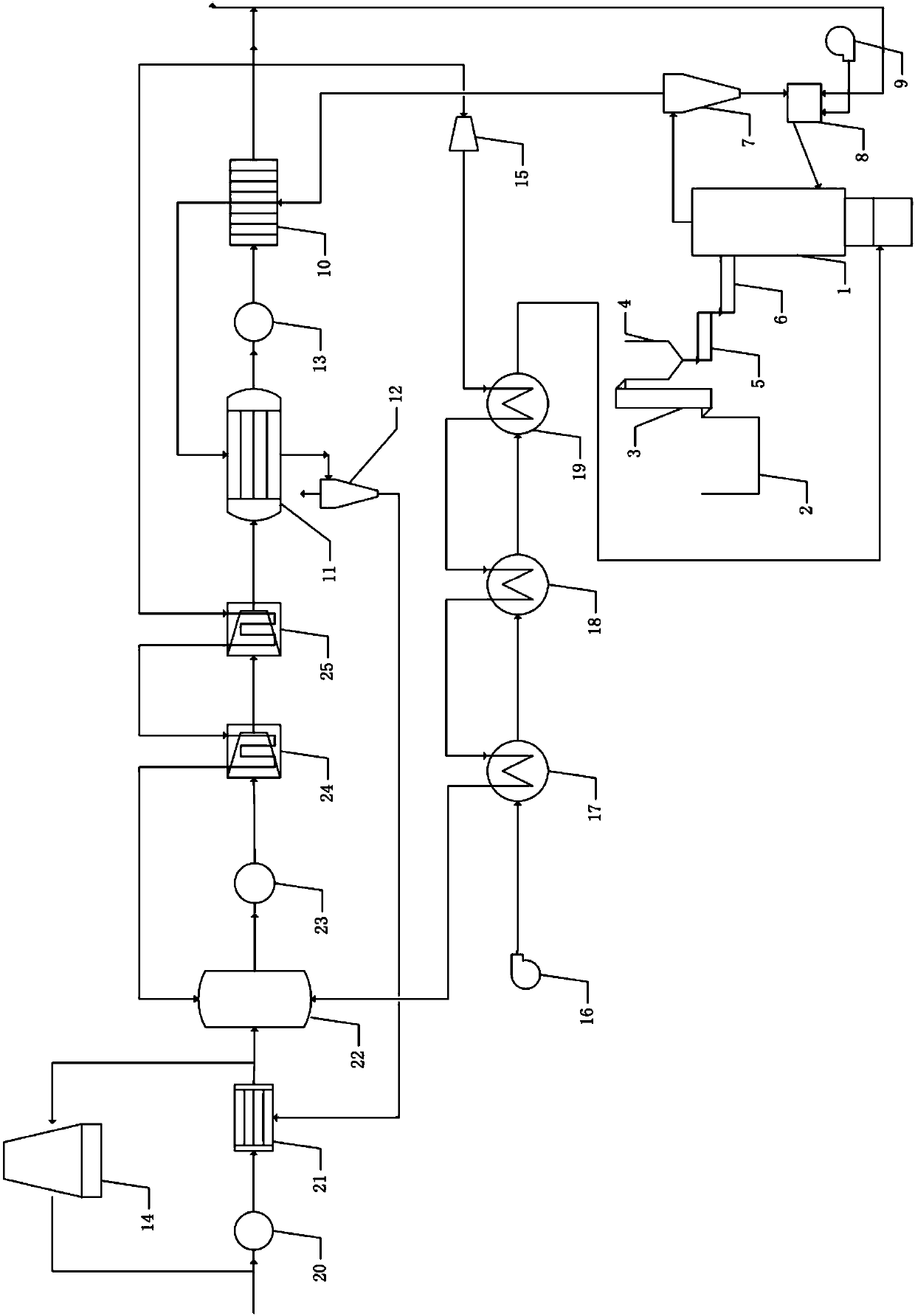

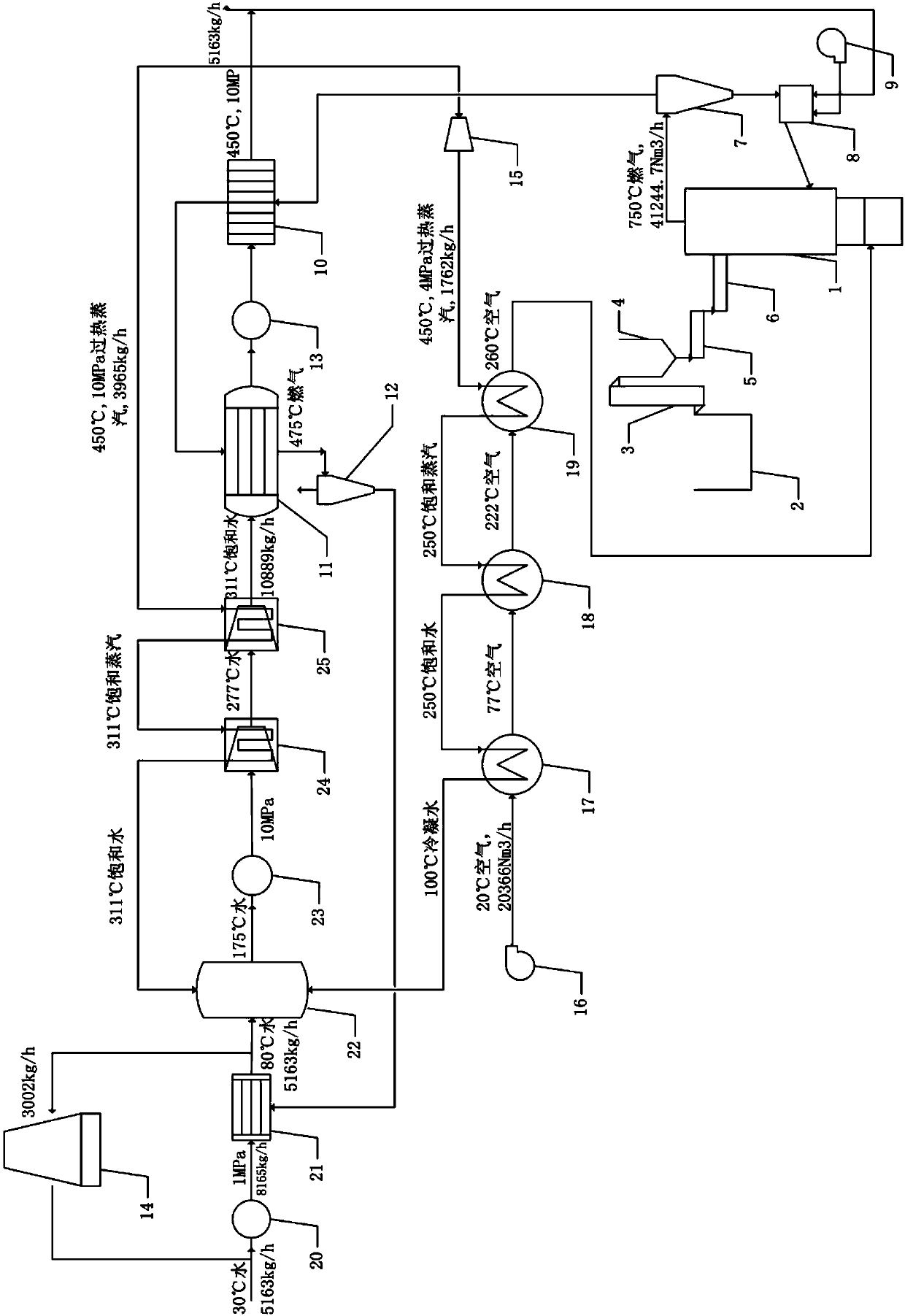

[0034] Such as figure 1 The biomass circulating fluidized bed gasification device shown includes a fluidized bed gasifier body 1, an air supply mechanism connected to the bottom end of the fluidized bed gasifier body 1, and an air supply mechanism arranged on the fluidized bed gasifier body 1. The feeding mechanism on the side, as well as the first-stage cyclone separator 7 and the feeder 8 forming a circulating fluidized structure with the fluidized bed gasifier body 1 .

[0035] The body 1 of the fluidized bed gasifier includes an upper dilute phase area, a lower dense phase area and a bottom air chamber. The side of the bottom air chamber of the fluidized bed gasifier body 1 is provided with a light oil burner and a fluidized bed gasifier body The 1 air chamber is connected, and the upper part of the fluidized bed gasifier body 1 air chamber is equipped with an air distribution plate and a wind cap.

[0036] The feeding mechanism includes a ground fabric bin 2, a hoist 3, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com