Flash spinning equipment and spinning method thereof

A technology of flash spinning and equipment, applied in the field of flash spinning equipment and spinning, can solve the problems of slow fiber condensation speed, difficult control of stability, difficult to control stability, etc., and achieve fast and uniform web formation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

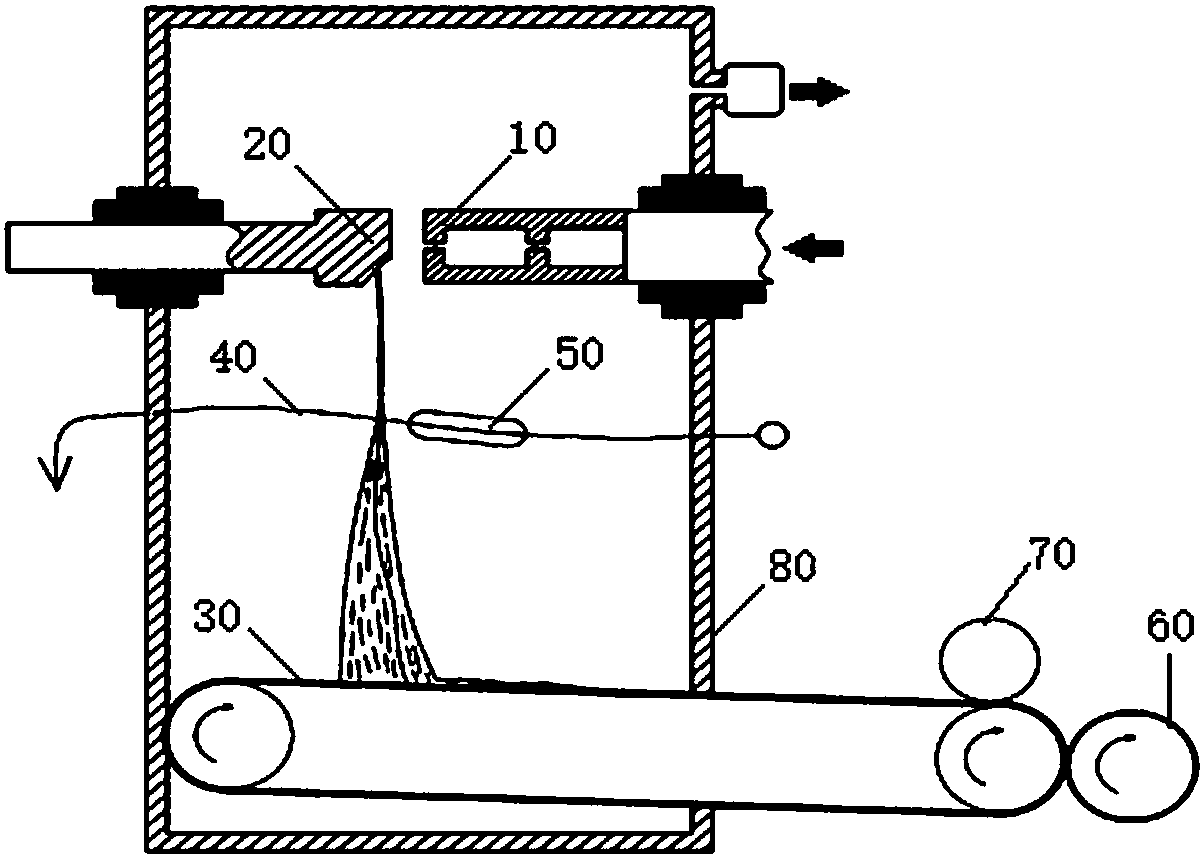

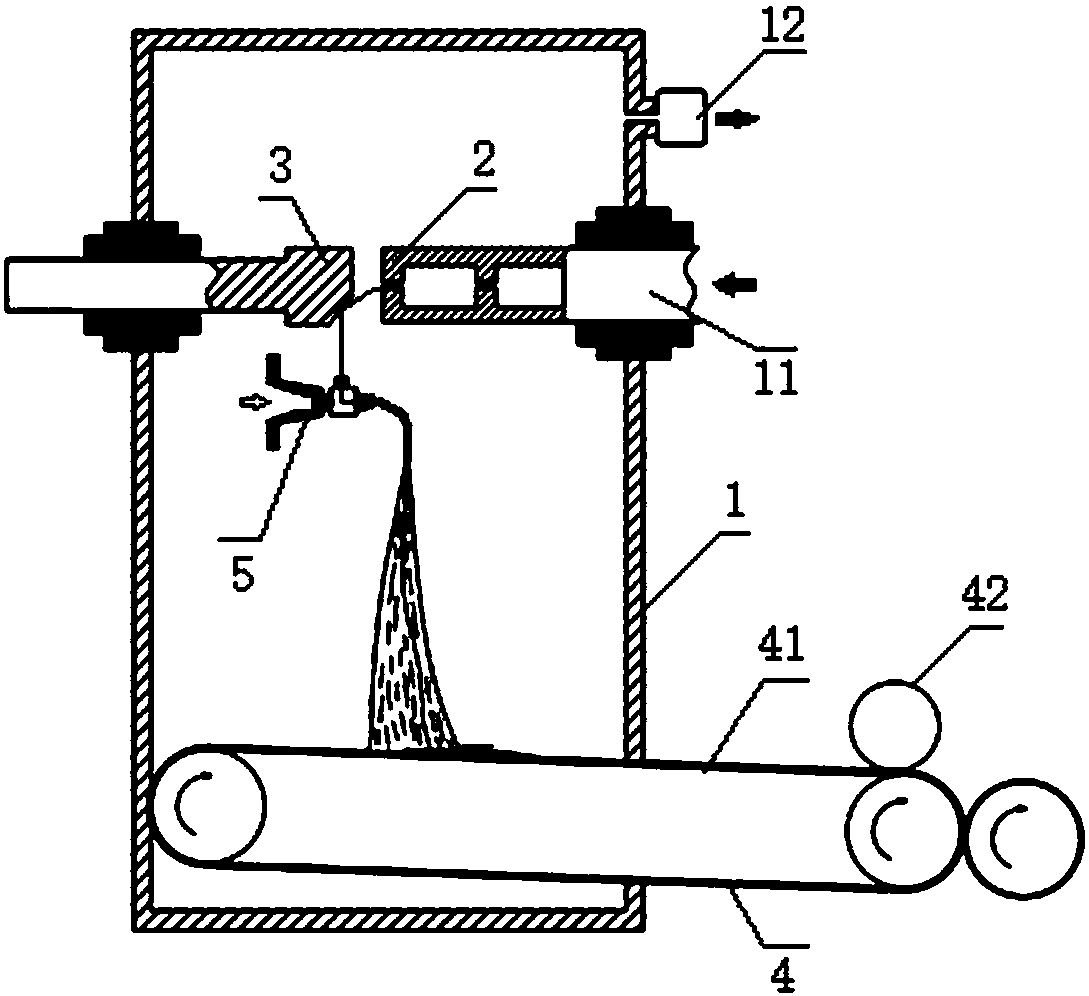

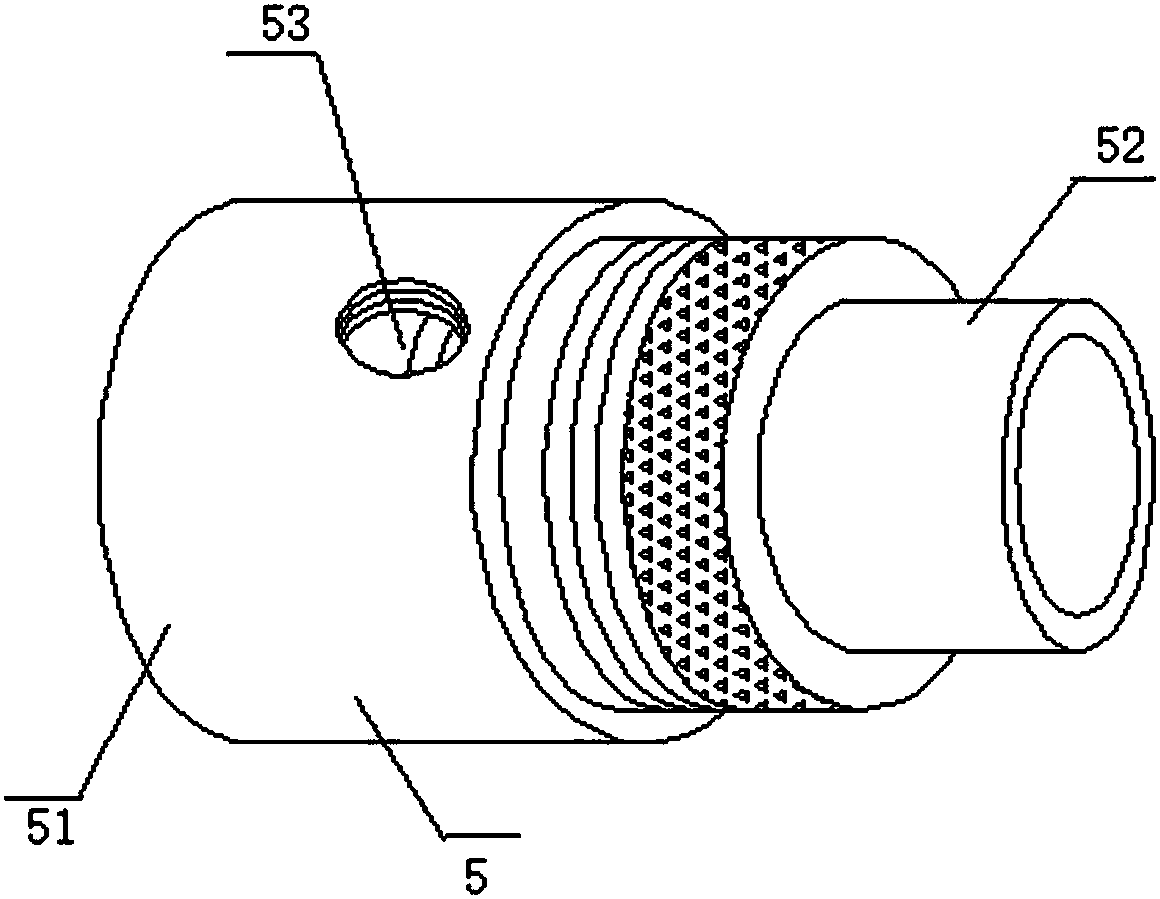

[0020] Such as figure 2 As shown, the present invention discloses a flash spinning equipment, comprising a box body 1, a spinneret 2, a turning plate 3 and a conveying device 4, and one side of the box body 1 is provided with a spinning stock solution inlet 11 and a spinning The material return port 12, the spinneret 2 is arranged on the inlet 11 of the spinning stock solution, and the spinning return port 12 is arranged on the top of the box body 1 for collecting the unused material blown out from the box body. spinning; the turning plate 3 is arranged on the other side of the box body 1 and is opposite to the spinneret 2, and the conveying device 4 for conveying the spun fiber web is arranged at the bottom of the box body 1, Also comprises air amplifier 5, and described air amplifier 5 is arranged between described turning plate 3 and described conveying device 4, and is arranged close to described turning plate 3, and the high-pressure air with fiber bundle that is drawn o...

Embodiment 2

[0023] The invention discloses a spinning method for flash spinning equipment, which comprises the steps of spraying the spinning stock solution from the spinneret, instantaneously evaporating the solvent of the spinning stock solution, rapidly cooling and solidifying the polymer in the spinning stock solution, forming fiber bundles, and The high-pressure air with fiber bundles is led to the air amplifier by the turning plate. The airflow velocity of the high-pressure air with fiber bundles is 6000-8000m / min. After passing through the compressed air inlet of the air amplifier, the annular cavity and the gap, the airflow generated by the air amplifier The speed is 12000-15000m / min; the airflow will carry out secondary drafting of the fiber bundles, and evenly open the fibers to form a fluffy network structure. After the fiber bundles settle on the accumulation belt to form a fiber web, the fiber web passes through the roller Hot rolled to form thin sheets.

Embodiment 3

[0025] The fiber fineness and fiber strength were tested for the fiber webs (experimental group) prepared by the present invention and the fiber webs (comparison groups 1 and 2) prepared by using the flash spinning equipment as described in the background technology, and the results are shown in Table 1.

[0026] Table 1 Fiber performance test of fiber web

[0027]

[0028] It can be seen that the fiber web prepared by the present invention has fine fibers and high strength. The fine fiber of the fiber net is beneficial to the filtration and waterproof of the product non-woven fabric, and the high fiber strength is conducive to the direct formation of the fiber net without compounding with other textiles, thus greatly expanding the use of the non-woven fabric prepared by the present invention.

[0029] In a word, the present invention adopts the air amplifier as the fiber opening element of the flash spinning equipment for the first time, and utilizes the principle of high-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com