A self-pressurizing wave energy device energy extraction system

A technology of energy extraction and wave energy, applied in accumulator devices, fluid pressure actuation devices, ocean energy power generation, etc., can solve the problem of large friction loss of hydraulic oil, low pressure of hydraulic oil, and installed capacity of only a few hundred watts and other problems, to achieve the effect of wide application range, not easy to be corroded and damaged, and important use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

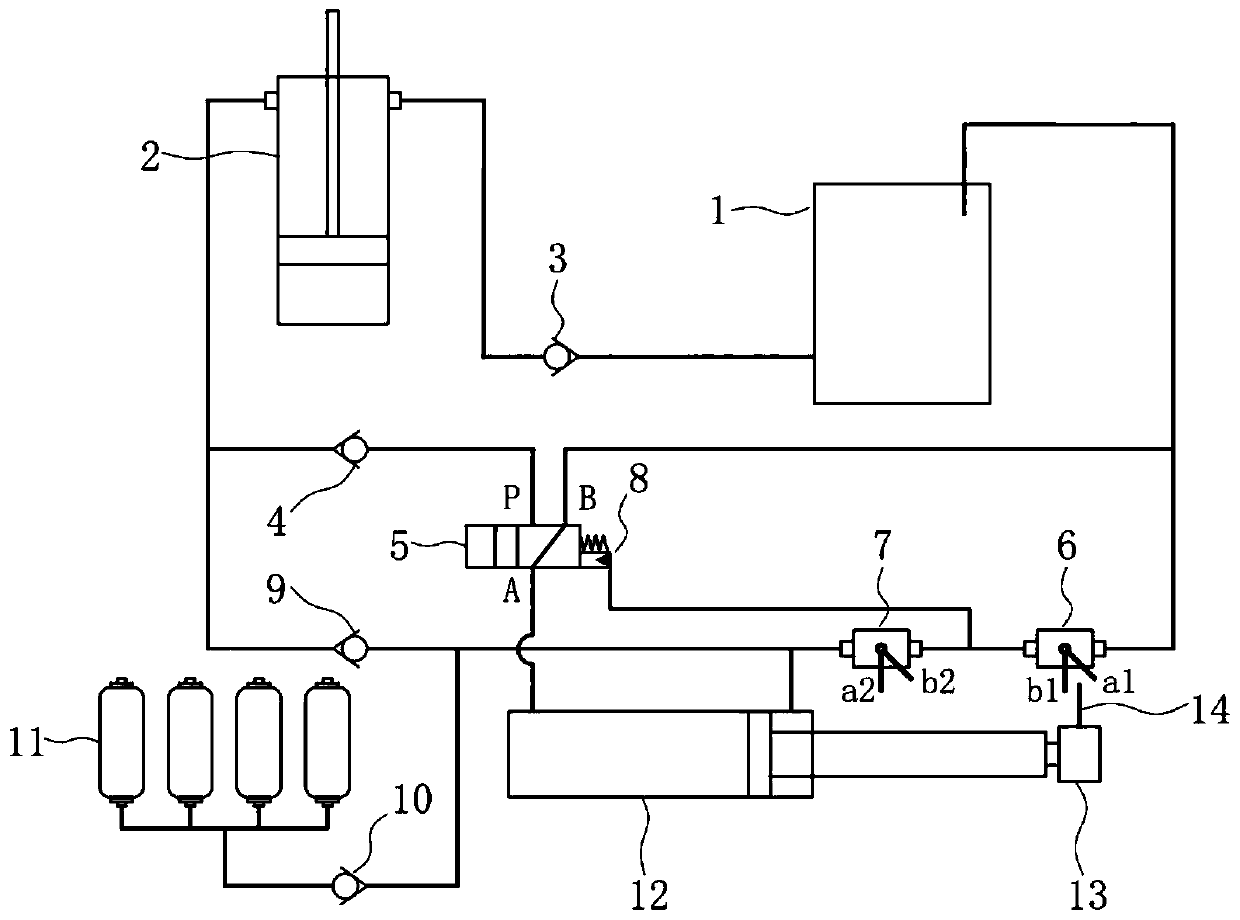

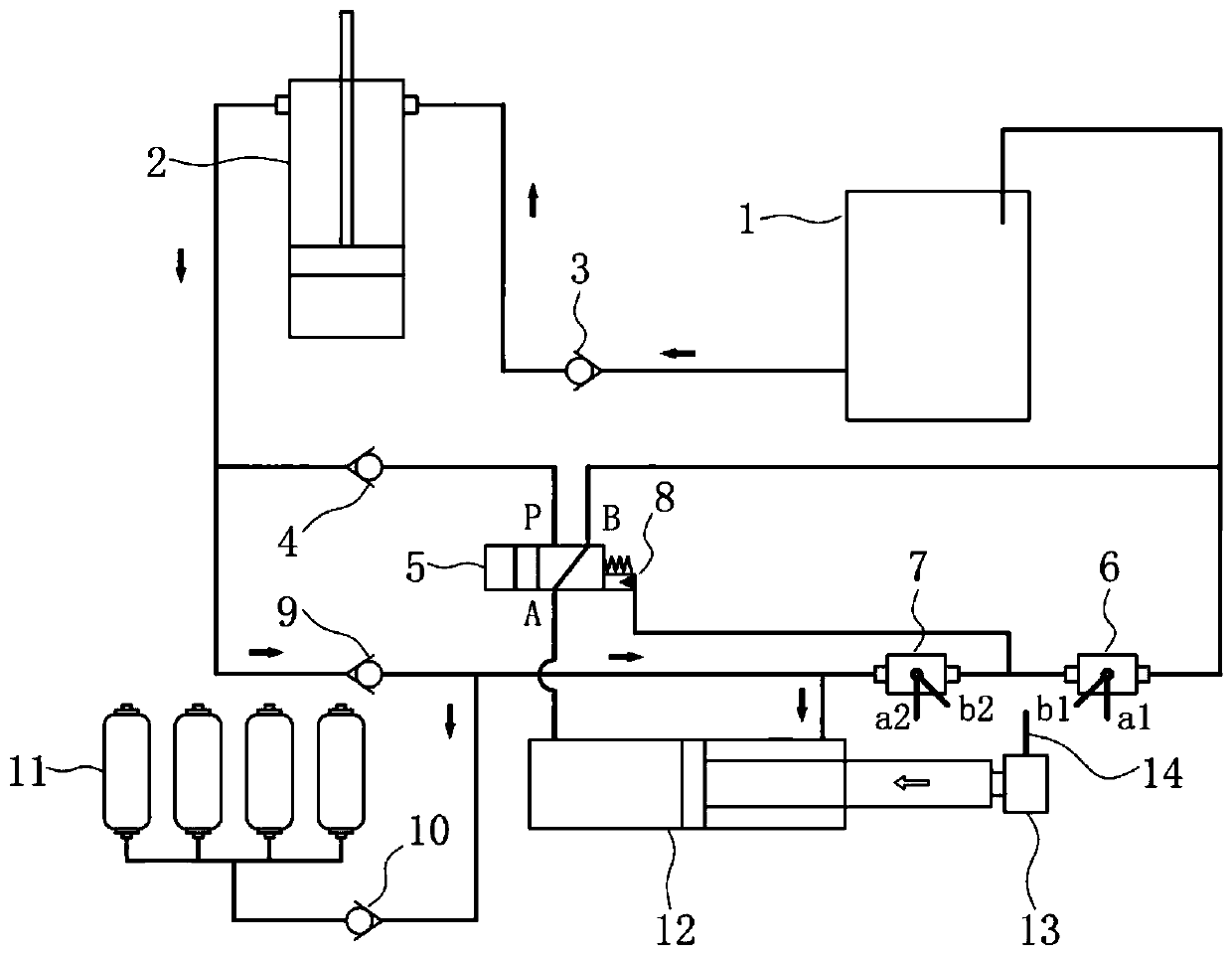

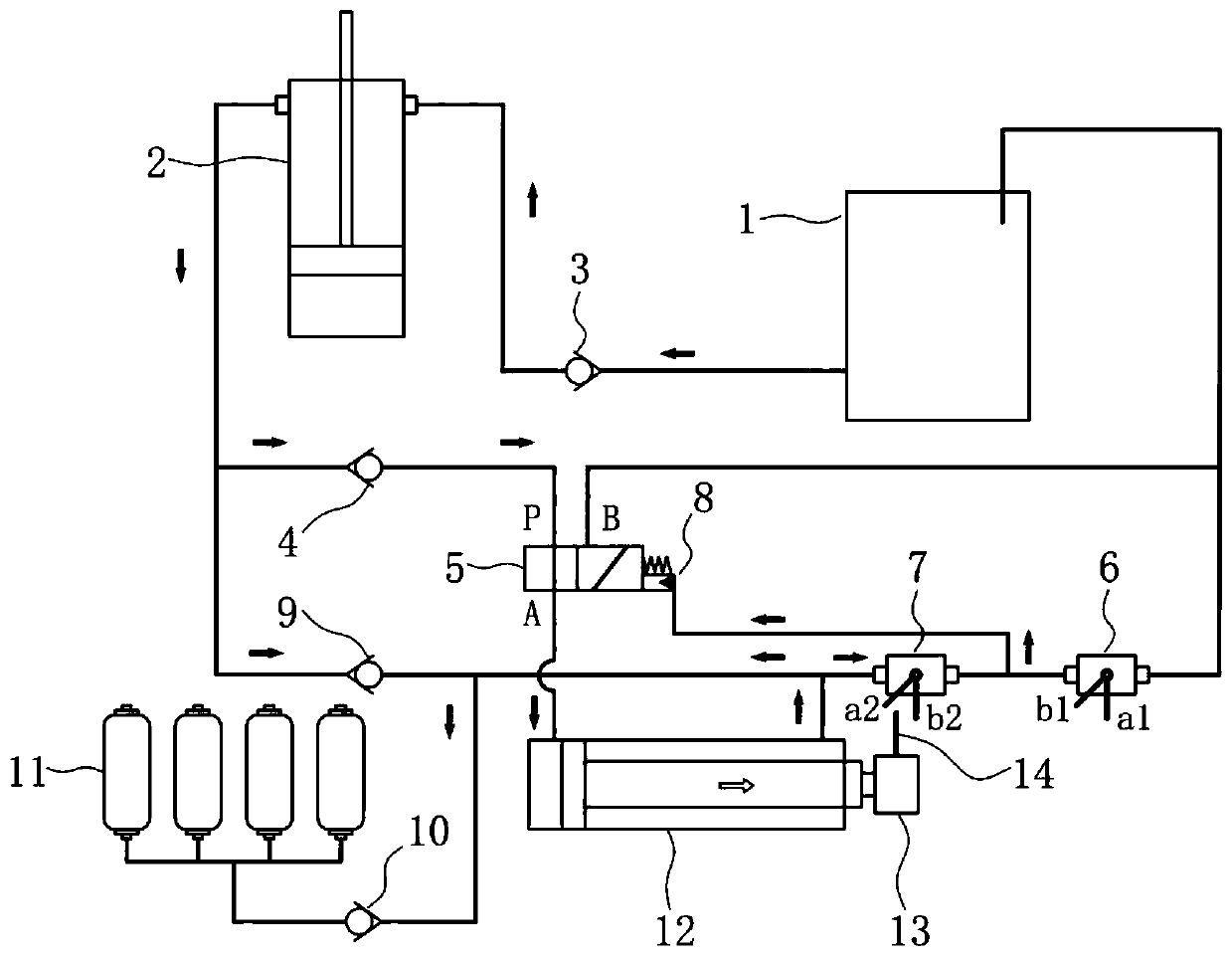

[0022] Such as figure 1 As shown, the automatically pressurized wave energy device energy extraction system of the present invention includes a fuel tank 1, a main hydraulic cylinder 2, a first one-way valve 3, a second one-way valve 4, a hydraulic reversing valve 5, a first ball valve 6. The second ball valve 7, the third one-way valve 9, the fourth one-way valve 10, the accumulator group 11 and the pressurized hydraulic cylinder 12.

[0023] The piston rod of the main hydraulic cylinder 2 is connected to the wave-absorbing floating body of the wave energy device. The outlet of the oil tank 1 is connected to the inlet of the rod chamber of the main hydraulic cylinder 2 through the first one-way valve 3, and the outlet of the rod chamber of the main hydraulic cylinder 2 passes through the second one-way valve. Valve 4, oil port P of hydraulic reversing valve 5, and oil port A of hydraulic reversing valve 5 communicate with the rodless chamber of pressurized hydraulic cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com