A kind of circuit board processing method

A processing method and circuit board technology, applied in the direction of printed circuit, printed circuit manufacturing, electrical components, etc., can solve the problem of excessive metal debris or glass fiber cloth debris, reduce the efficiency of cutting and edging copper clad laminates, and increase the processing cycle of copper clad laminates and other problems, to achieve the effect of improving cutting and edging efficiency, facilitating movement and cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Further detailed explanation through specific implementation mode below:

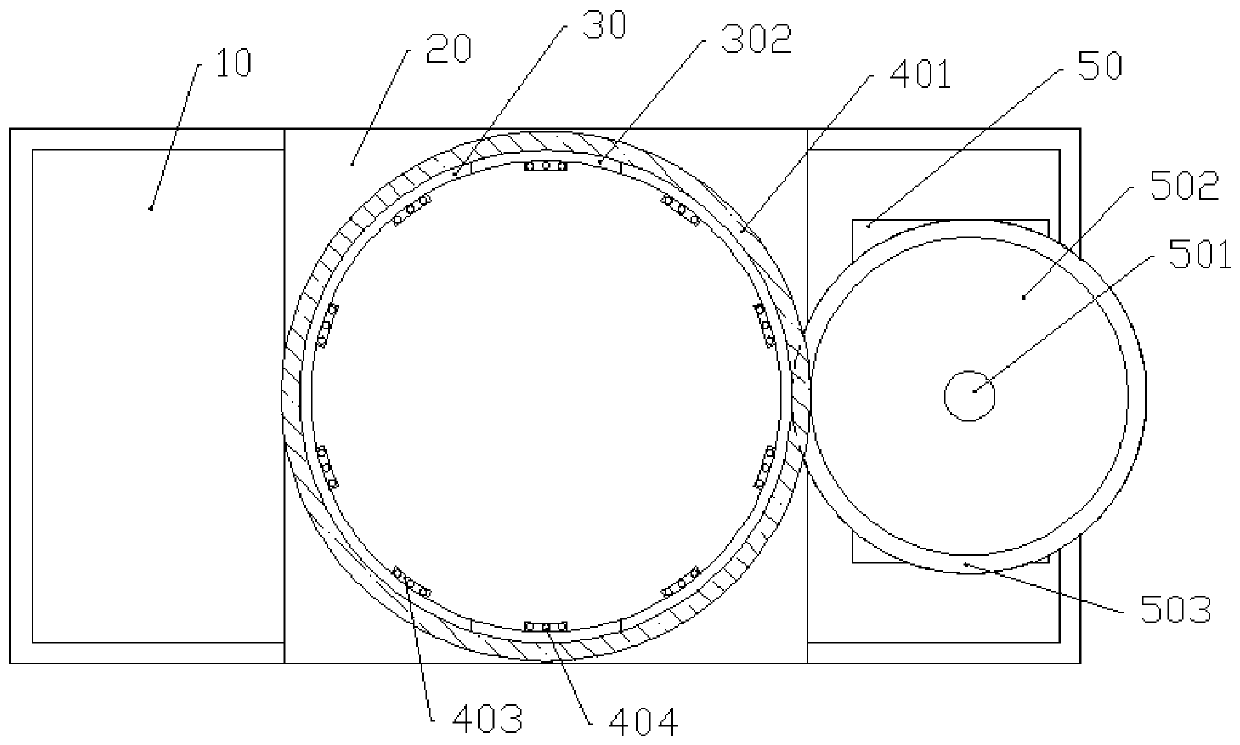

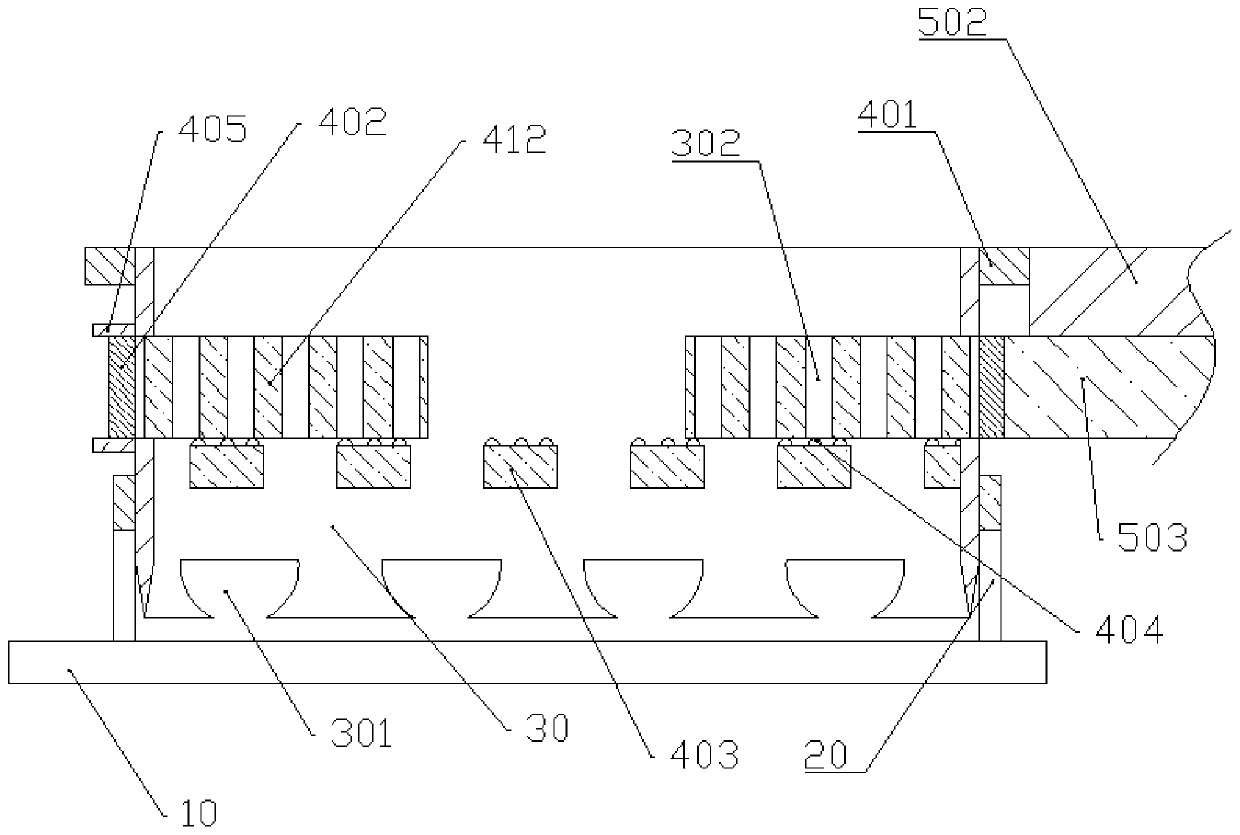

[0022] The reference numerals in the accompanying drawings include: cutting table 10, bracket 20, cutter 30, incision 301, grinding through groove 302, first ring gear 401, second ring gear 402, grinding teeth 412, wedge 403, ball 404 , the limit ring 405 , the motor 50 , the transmission shaft 501 , the first driving gear 502 , and the second driving gear 503 .

[0023] The cutting device in the embodiment is basically as attached figure 1 And attached figure 2 Shown: including cutting table 10, cutting mechanism and grinding mechanism.

[0024] Cutting mechanism comprises annular cutting knife 30 and support 20, and support 20 is welded on the cutting table 10, and cutting knife 30 is vertically slidably installed on the support 20, and the lower end of cutting knife 30 is provided with blade, and one end of cutting knife 30 blade Opposite to the upper surface of the cutting table 10 , a pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com