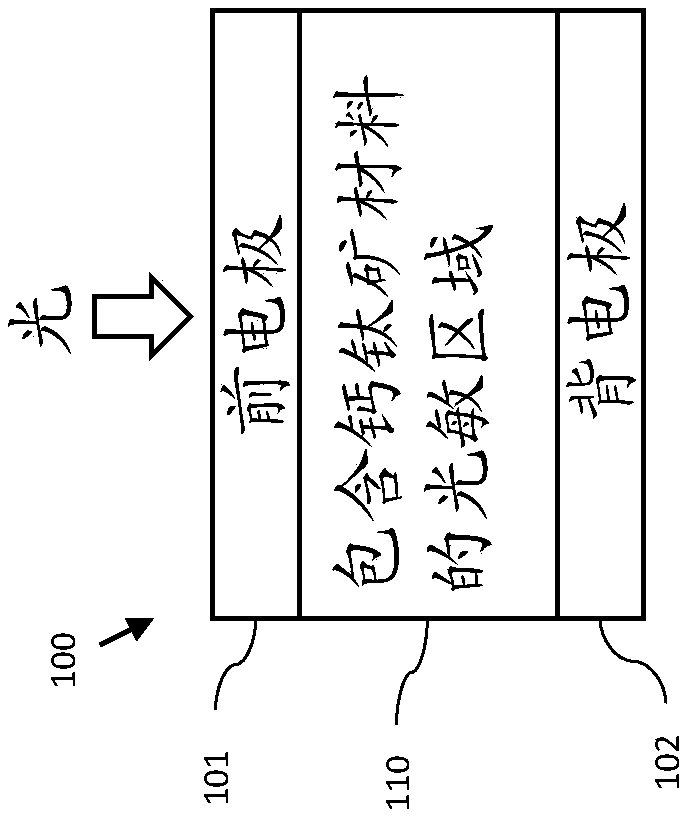

Method of depositing a perovskite material

A technology of perovskite materials and inorganic materials, applied in metal material coating technology, liquid chemical plating, electrolytic capacitors, etc., can solve the problems of reducing the efficiency of silicon cells and increasing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] definition

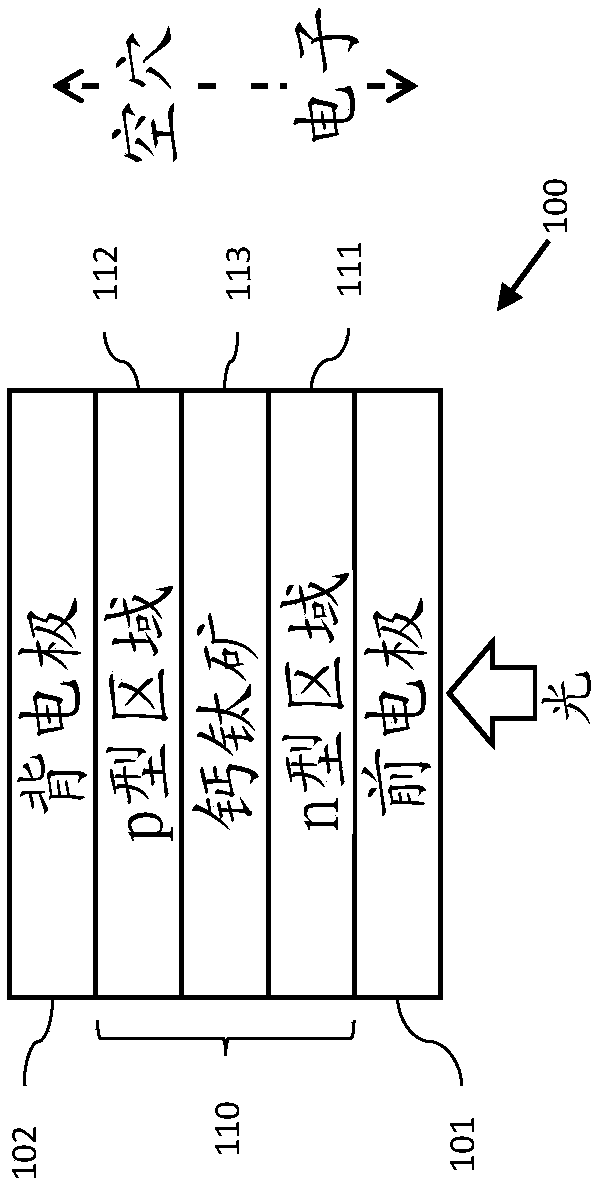

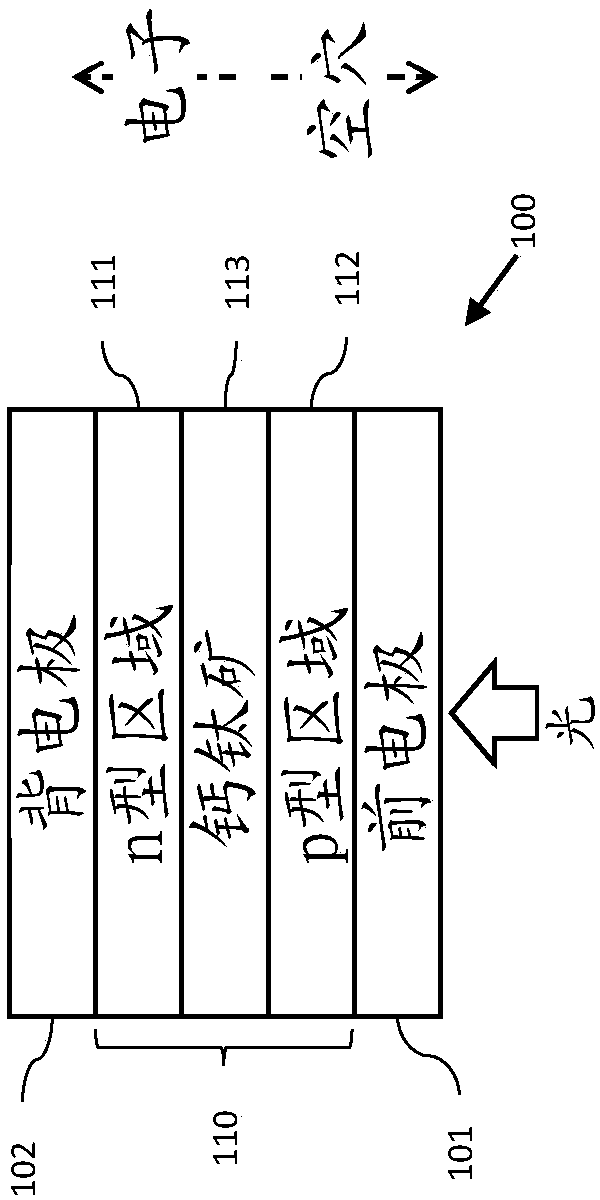

[0076] The term "photosensitive" as used herein refers to a region, layer or material capable of photoelectrically responding to light. A photosensitive region, layer or material is thus capable of absorbing energy carried by photons of light, which subsequently leads to the generation of electricity (for example by generating electron-hole pairs or excitons).

[0077] The term "conformable" as used herein refers to an object that is substantially the same in form or shape as another object. Thus, "conformal layer" as used herein refers to a layer of material that conforms to the contours of the surface on which it is formed. In other words, the morphology of the layer is such that the thickness of the layer is approximately constant over most of the interface between the layer and the surface on which the layer is formed.

[0078] The term "perovskite" as used herein refers to a 3A material with a structurally related three-dimensional crystal structure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com