High-efficiency red tea fermenting machine

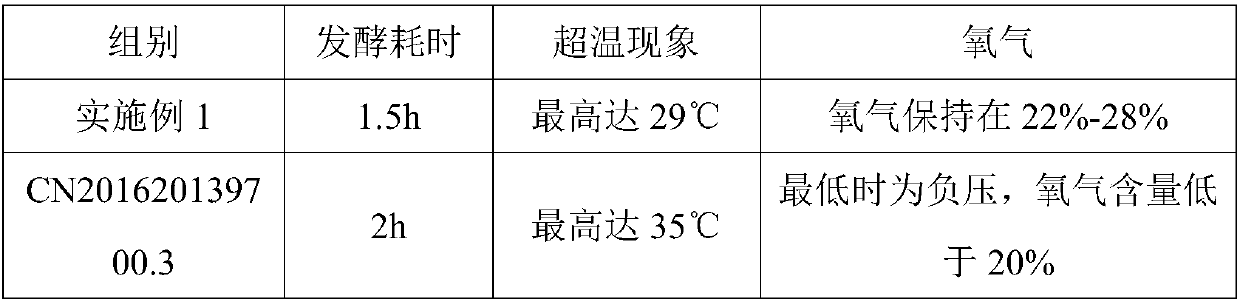

A fermentation machine and high-efficiency technology are applied in the field of high-efficiency black tea fermentation machines, which can solve the problems of lack of air circulation, inability to ensure the uniformity of black tea fermentation quality, and difficulty in achieving overall balance and unity, and achieve the effect of ensuring quality and improving fermentation quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

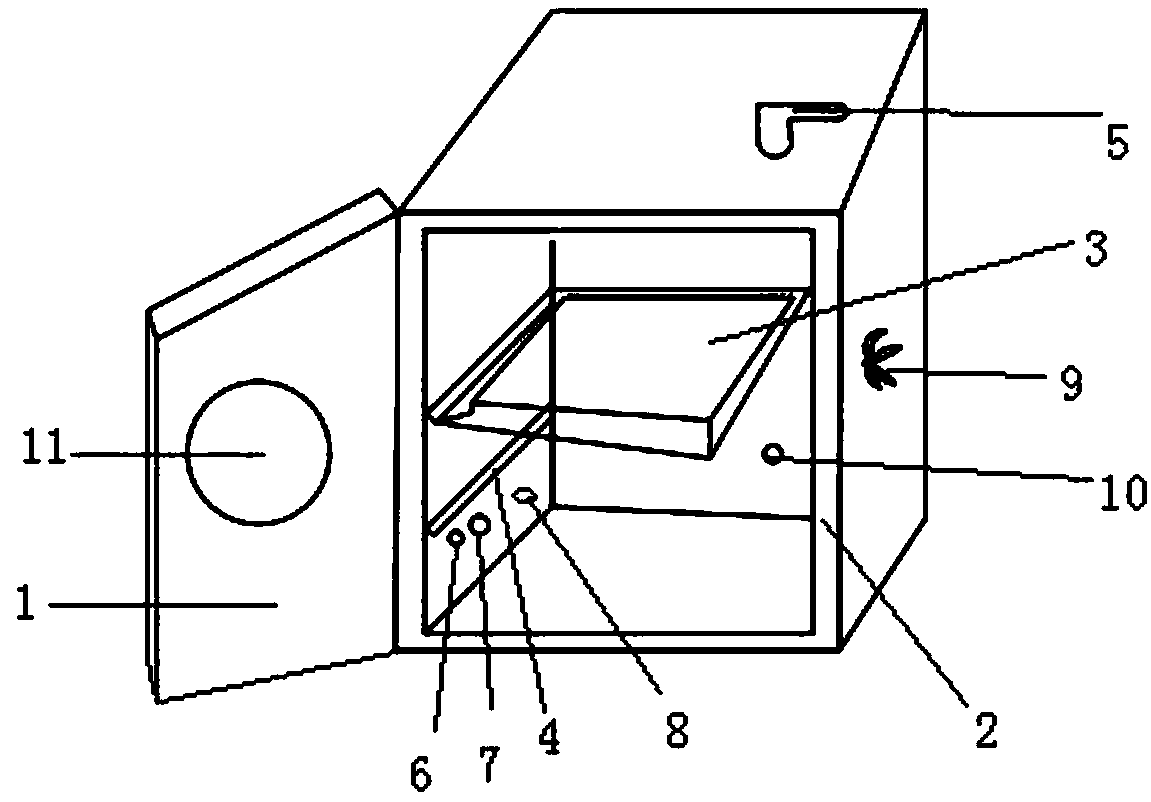

[0022] Black tea high-efficiency fermentation machine, including box body 2 and box door 1, and also includes moisture adjustment module 6, ozone adjustment module 8, oxygen adjustment module 7, exhaust channel 5, exhaust fan 9, observation lamp, glass viewing cup, and multiple horizontal pipes , pallet, 6 pieces of the moisture adjustment module, 8 ozone adjustment modules, and 7 oxygen adjustment modules are located under the box body 1 and installed in sequence, the exhaust fan 9 is located on the box body opposite the moisture adjustment module 6, and the exhaust channel 5 One end passes through the top of the box body 1, the other end is outside the box body 1, the observation lamp 10 is below the box body 2 corresponding to the box door 1, the glass sight cup 11 is located in the center of the box door 1, and the multiple horizontal lines The tubes 4 are arranged symmetrically and evenly on the box body 2 on both sides of the box door 1 , and the tray 3 is located on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com