Environment-friendly smoke collecting, adjusting and control device and application thereof

A technology of regulating control and flue gas collection, which is applied in the direction of removing smoke and dust, cleaning methods and utensils, cleaning hollow objects, etc., can solve the problems of inability to differentiate the control of charcoal kilns, etc., and achieve a clever and scientific structure design. , to avoid the effect of smoke leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

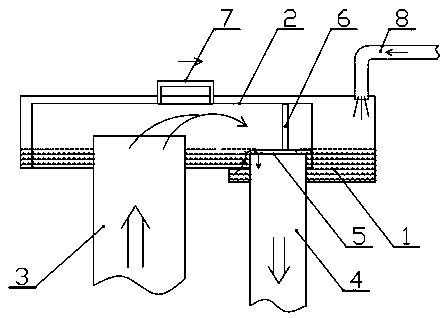

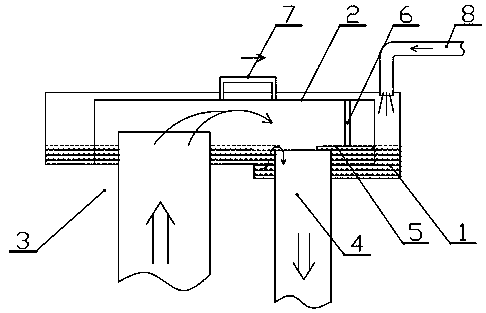

[0018] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

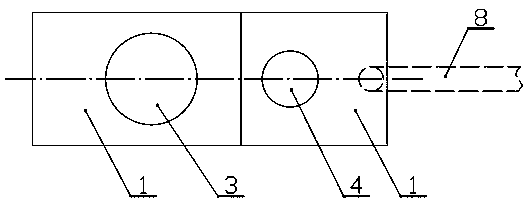

[0019] see Figure 1 to Figure 5 , the environment-friendly flue gas collection adjustment control device of the present invention includes a tank body 1 and a cover body 2 buckled inside the tank body 1. In this embodiment, the length and width of the cover body 2 are smaller than the tank body 1, that is, The cover body 2 can move left and right along the tank body 1 .

[0020] The bottom of the tank body 1 is pierced with a flue gas inlet pipe 3 and a flue gas discharge pipe 4, the upper ends of the flue gas inlet pipe 3 and the flue gas discharge pipe 4 are located in the cover body 2, and the flue gas The nozzle height of the air inlet pipe 3 is higher than that of the smoke discharge pipe 4, so that the smoke discharge pipe 4 also f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com