Method of additively manufacturing metal composite board with built-in circuit

A metal composite plate and additive manufacturing technology, applied in the field of additive manufacturing, can solve problems such as increasing processing costs and reducing mechanical properties of composite plates, and achieves the effects of improving forming efficiency, improving mechanical properties, and expanding application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

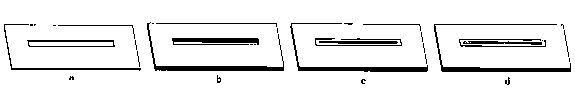

Image

Examples

Embodiment 1

[0030] Example 1: A method for additively manufacturing iron-aluminum composite panels with built-in circuits

[0031] (1) Model the iron-aluminum composite board that needs a built-in circuit, set the circuit path and position in the iron-aluminum composite board, repair the model with Magic software, and then slice the model with Autofab software, the thickness of the slice is iron foil The thickness of the material, in which the thickness of the iron foil material is the same as that of the aluminum foil material. The forming accuracy is controlled at 1mm;

[0032] (2) Cut out the circuit path on the iron foil material according to the set circuit path. The thickness of the iron foil is 0.5mm, the rotation speed of the cutter is 50r / s, the moving speed of the cutter is 0.5m / s, and the chamfering of the edge of the cutter is 0.5mm; after cutting, clean the iron foil with alcohol and dry it;

[0033] (3) The iron foil material is consolidated and formed by an ultrasonic con...

Embodiment 2

[0040] A method for additively manufacturing titanium-aluminum composite board with built-in circuit

[0041] (1) Model the titanium-aluminum composite board that needs a built-in circuit, set the circuit path and position in the titanium-aluminum composite board, repair the model with Magic software, and then slice the model with Autofab software, the thickness of the slice is titanium foil The thickness of the material, in which the thickness of the titanium foil is the same as that of the aluminum foil. The forming accuracy is controlled at 1mm;

[0042] (2) Cut out the circuit path on the titanium foil according to the set circuit path. The thickness of the titanium foil is 0.2mm, the rotation speed of the cutter is 80r / s, the moving speed of the cutter is 0.8m / s, and the chamfering of the cutter boundary is 0.8mm; after cutting, clean the iron foil with alcohol and dry it;

[0043] (3) Consolidate the titanium foil into shape through an ultrasonic consolidation device. ...

Embodiment 3

[0050] A method for additively manufacturing titanium-iron composite board with built-in circuit

[0051] (1) Model the titanium-iron composite board that needs a built-in circuit, set the circuit path and position in the titanium-iron composite board, use Magic software to repair the model, and then use Autofab software to slice the model, and the thickness of the slice is titanium foil The thickness of the material, in which the thickness of the titanium foil is the same as that of the iron foil. The forming accuracy is controlled at 0.5mm;

[0052](2) Cut out the circuit path on the titanium foil according to the set circuit path. The thickness of the titanium foil is 0.3mm, the rotation speed of the cutter is 90r / s, the moving speed of the cutter is 0.75m / s, and the chamfering of the cutter boundary is 0.5mm; after cutting, clean the iron foil with alcohol and dry it;

[0053] (3) Consolidate the titanium foil into shape through an ultrasonic consolidation device. The u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com