Electro-hydraulic control system of sugarcane harvester

An electro-hydraulic control system and control system technology, applied in the field of machinery, can solve problems such as low driving speed, high power consumption for walking, frequent load changes of sugarcane harvesters, etc., and achieve the goal of increasing operating speed, smooth operation, and improving work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with drawings and embodiments.

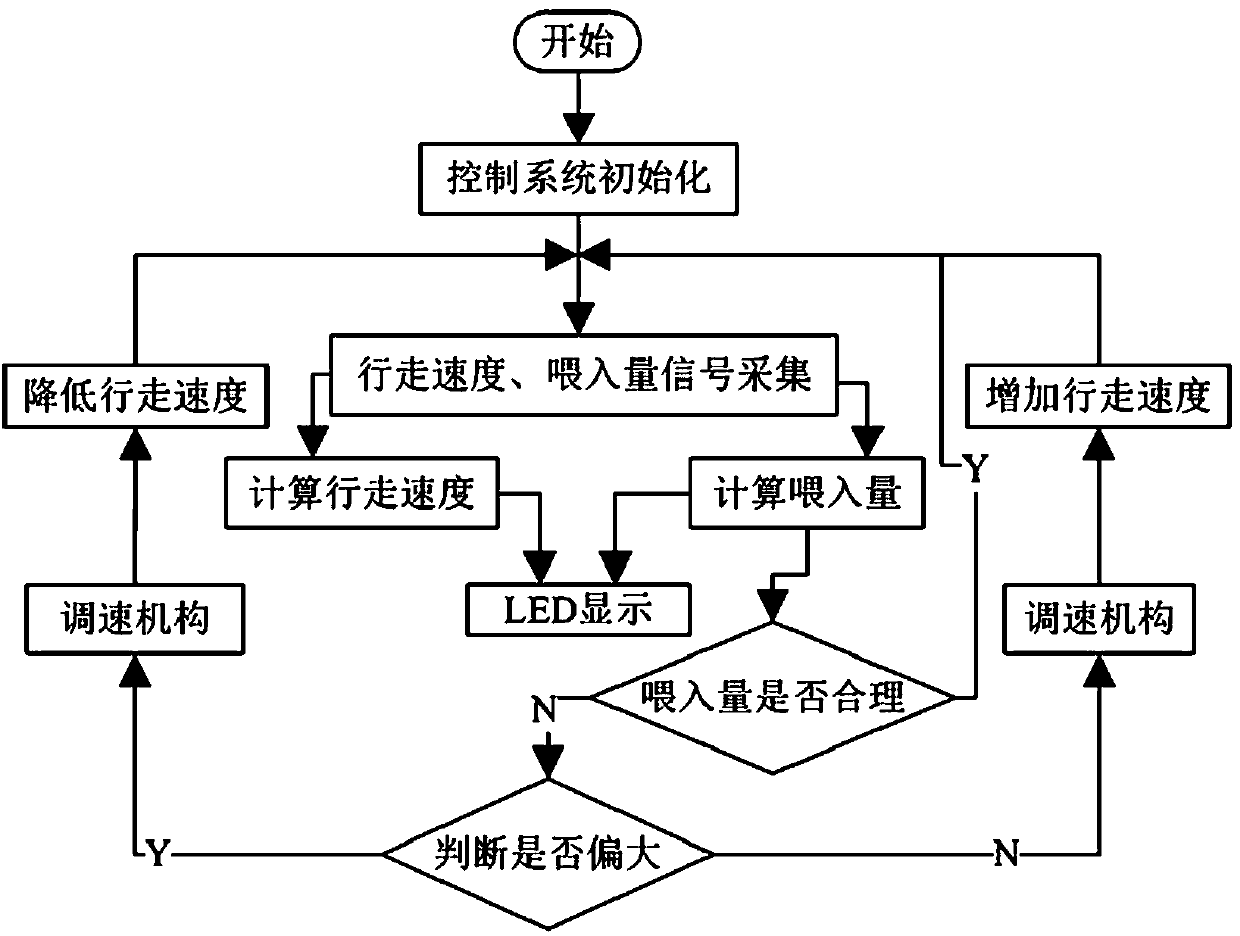

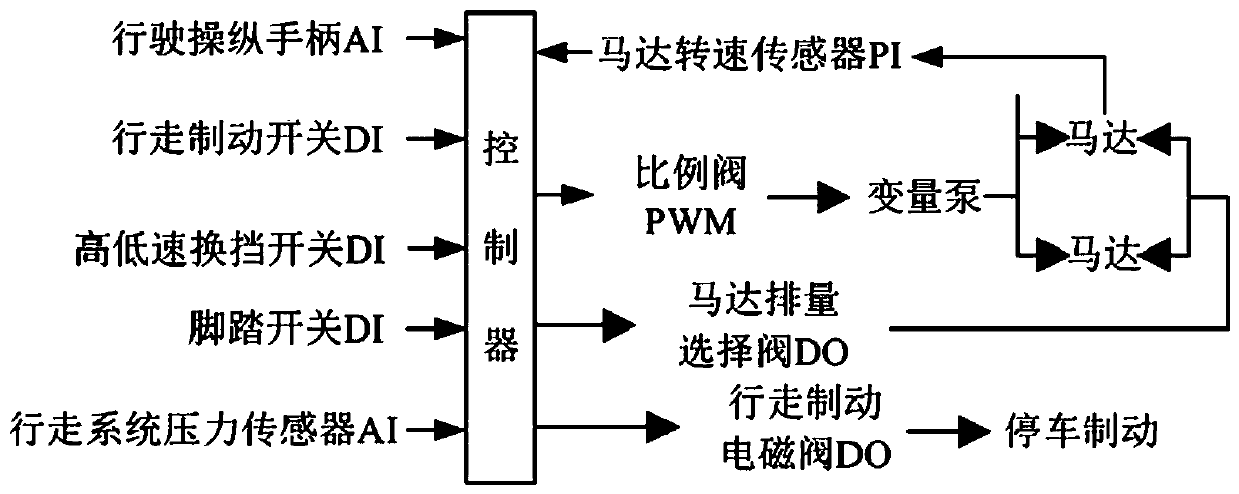

[0026] Such as figure 1 , the value of the feeding amount is obtained by summarizing the lower roller motor speed, root cutting motor speed, coil motor speed, root cutting circuit pressure, conveying circuit pressure and walking hydraulic system pressure into the controller through comprehensive analysis in the control system from. The rated feeding amount of this type of sugarcane harvester can be defined through the specific test method, and the rated feeding amount is set when the controller is programmed, and the rest of the parameters are preset according to the working conditions of the rated feeding amount, when each When there is a difference between the parameter and the preset parameter, the controller will output the corresponding PWM signal for adjustment, so that it returns to the preset parameter range. When the harvester is working normally, press the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com