Manufacturing method of home decoration door plank

A manufacturing method and door panel technology, applied in the manufacture of tools, wood processing appliances, etc., can solve the problems of low strength and poor nail-holding ability, achieve stable performance, increase strength, and avoid poor nail-holding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Referring to the accompanying drawings, a method for making a home improvement door panel according to the present invention will be described in detail below.

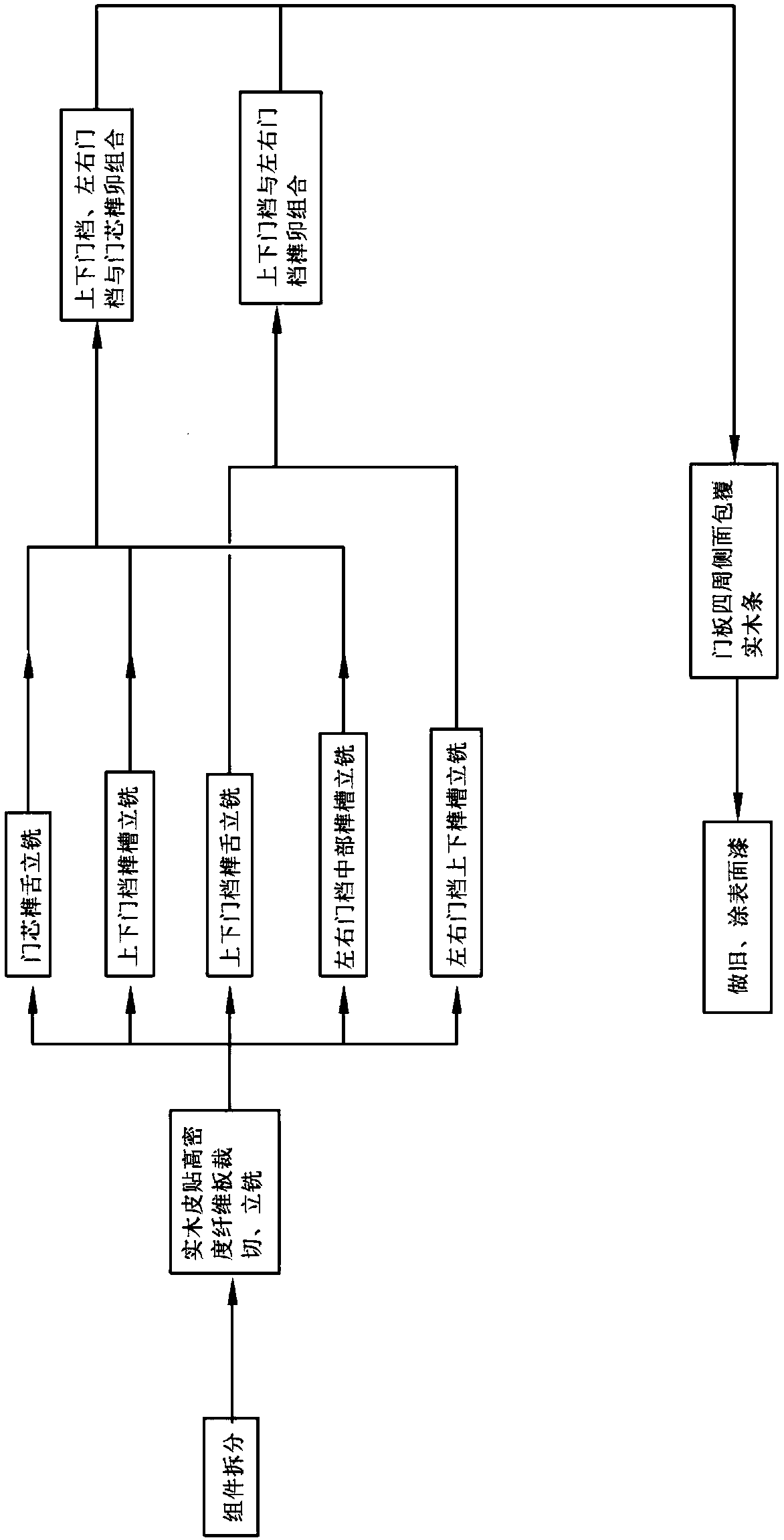

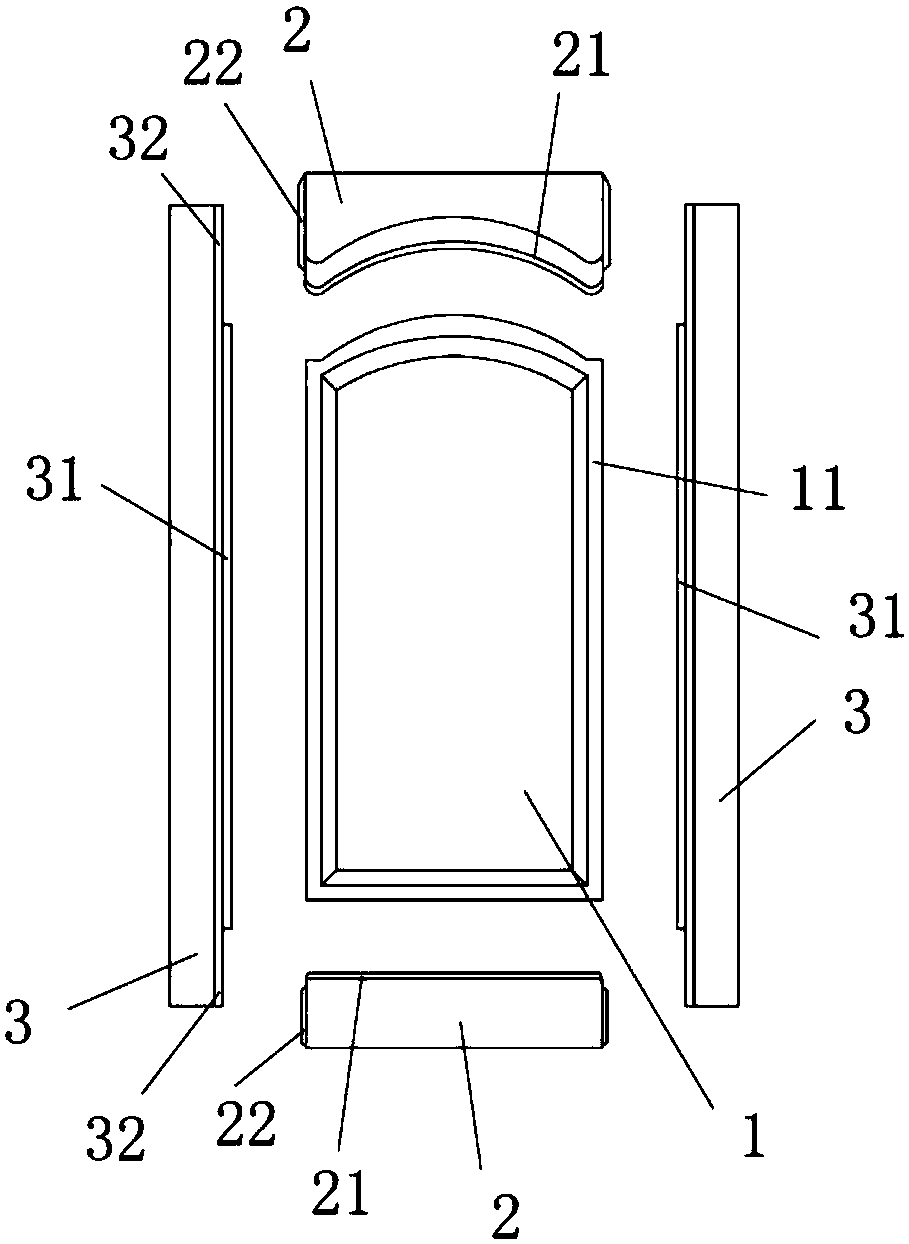

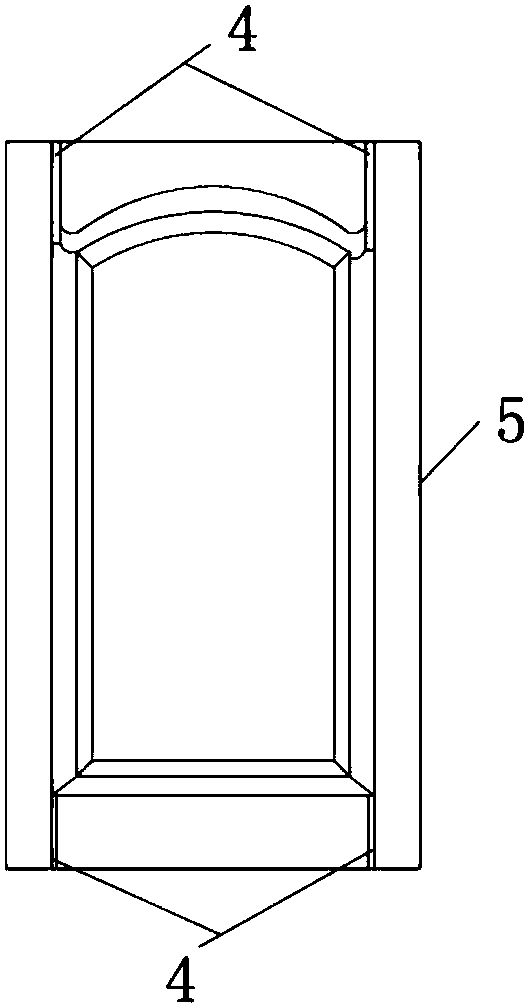

[0019] Such as figure 1 , 2 , 3, a method for making a home improvement door panel, comprising the following steps: (1) splitting the door panel into five components: door core 1, upper and lower door rails 2, left and right door edges 3, according to the size and shape of the components, Use hot-pressed high-density fiberboard pasted with solid wood veneer to cut and end-mill the upper and lower door stops 2 and the left and right door sides 3; end-mill the inner side of the upper and lower door stops 2 to form a tenon and groove 21, and end-mill the inner side of the left and right door sides 3 to form a tenon and groove 31, corresponding to the tongue 11 that is milled around the door core 1; the tongue 22 that is milled on the left and right sides of the upper and lower door stops 2, corresponding to the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap