UV printing machine printing mechanism with simple structure

A technology with a simple structure and a printing mechanism, which is applied in the direction of printing machines, rotary printing machines, general parts of printing machinery, etc., can solve problems such as blurred pictures, complex structures, troublesome maintenance, etc., and achieve the effect of ensuring the printing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

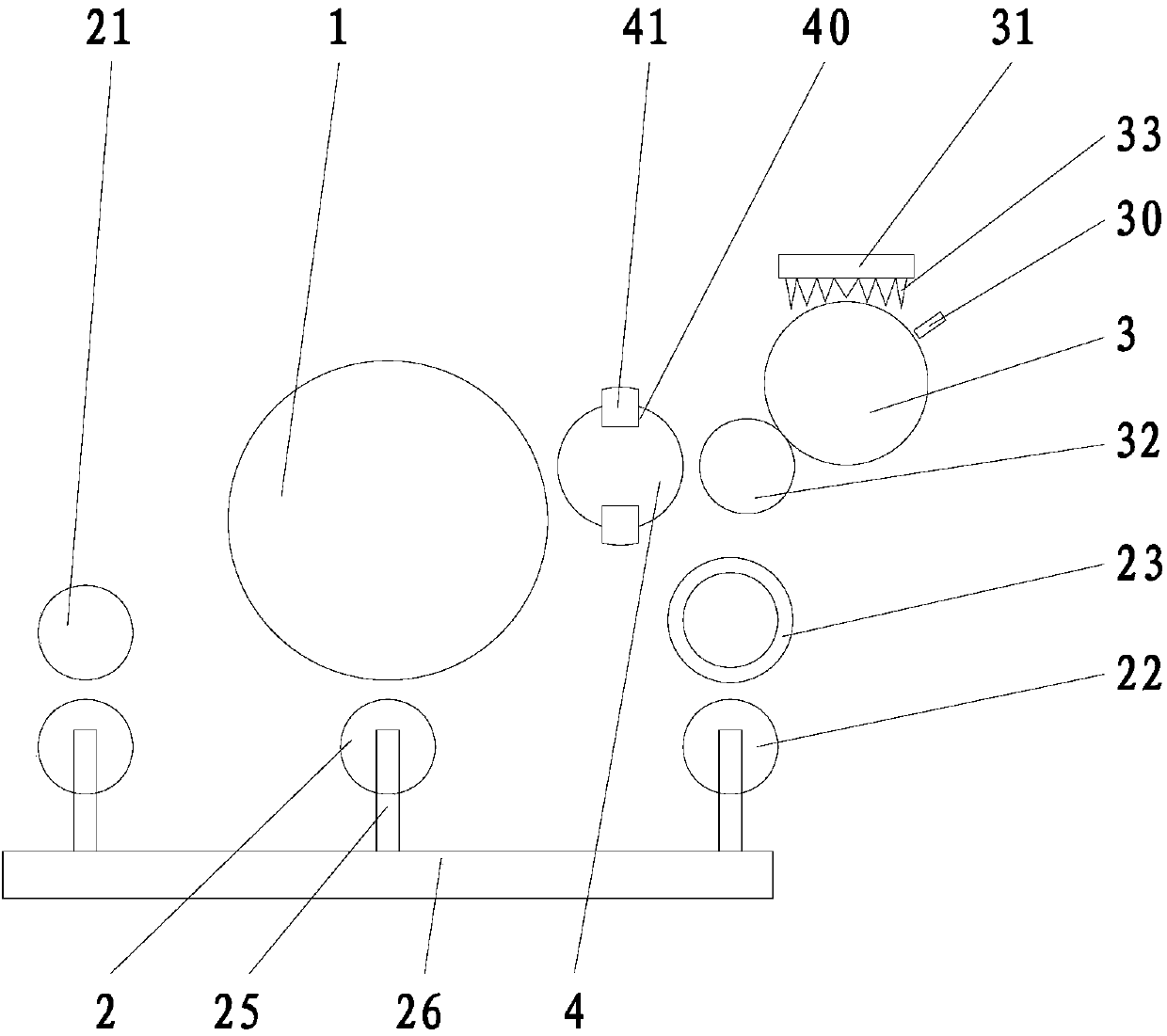

[0015] refer to figure 1 , a UV printer printing mechanism with simple structure in the present invention, including inkjet head 30, scraper 31, ink equalizing stick 3, ink sticking stick 32, plate stick 4, ink transfer stick 1, support 25, along the direction of cardboard running The feeding rollers 21, printing support rollers 2, and discharging rollers 22 arranged in sequence, the number of the feeding rollers 21 and the discharging rollers 22 is 2, the two feeding rollers 21 are distributed up and down, and the two discharging rollers 22 are distributed up and down, the feed roller 21 below, the printing support roller 2 and the discharge roller 22 below all correspond to a bracket 25, the bracket 25 is U-shaped, the feed roller 21 below, the printing support roller 2 and the The discharge stick 22 below is all installed on the support 25, and all supports 25 are all connected with the same lifting device 26, and the periphery of the described ink stick 3 is provided with ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap