Surface treatment method for inhibiting overplating of electronic ceramic element and electronic ceramic element

An electronic ceramic component and surface treatment technology, applied in the field of electronic ceramics, can solve the problems of easy plating of nickel layer and tin layer on the surface of the product, poor appearance of the product, conduction and short circuit of the surface layer, etc. The effect of increasing surface resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

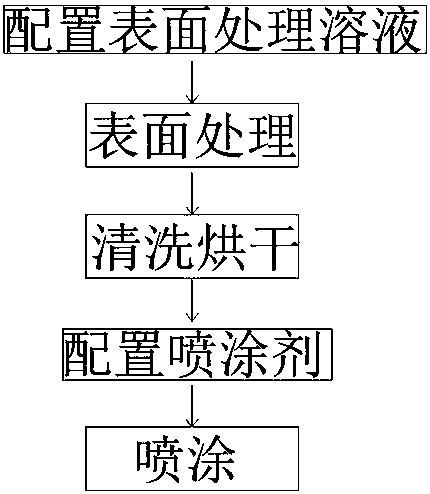

[0033] refer to figure 1 A surface treatment method for suppressing creep plating of electronic ceramic components, comprising the following steps:

[0034] S1: Prepare a surface treatment solution: mix the mixed material with water evenly to obtain a surface treatment solution. The mixed material includes perchloric acid and a catalyst;

[0035] S2: Surface treatment: soak the electronic ceramic components in the surface treatment solution to form a spray coating on the surface of the electronic ceramic components;

[0036] S3: Cleaning and drying: cleaning the surface residues of the electronic ceramic components treated in step S2, and drying the electronic ceramic components;

[0037] S4: Prepare spraying agent: Propionaldehyde, propane, propylene and ethylene are selected as raw materials and mixed. %, ethylene 15% to 25%;

[0038] S5: Spraying: Spraying is carried out by thermal spraying method, and the temperature is lowered after spraying.

[0039] The time of soak...

Embodiment 2

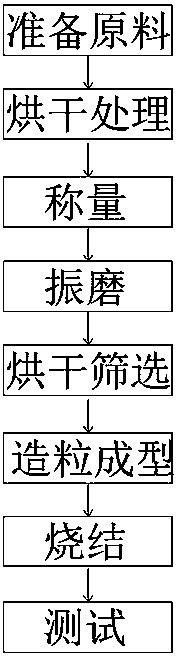

[0051] S1: Prepare a surface treatment solution: mix the mixed material with water evenly to obtain a surface treatment solution. The mixed material includes perchloric acid and a catalyst;

[0052] S2: Surface treatment: soak the electronic ceramic components in the surface treatment solution to form a spray coating on the surface of the electronic ceramic components;

[0053] S3: Cleaning and drying: cleaning the surface residues of the electronic ceramic components treated in step S2, and drying the electronic ceramic components;

[0054] S4: Prepare spraying agent: a-cyanoacrylate, propionaldehyde, propane, propylene and ethylene are used as raw materials to mix and make, and the components and the concentration of each component are 20% to 40% of propionaldehyde and 20% to 30% of propane. %, 5% to 10% of propylene, 10% to 20% of ethylene, 10% to 30% of a-cyanoacrylate;

[0055] S5: Spraying: Spraying is carried out by thermal spraying method, and the temperature is lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com