Compound, colorant composition comprising the same and resin composition comprising the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

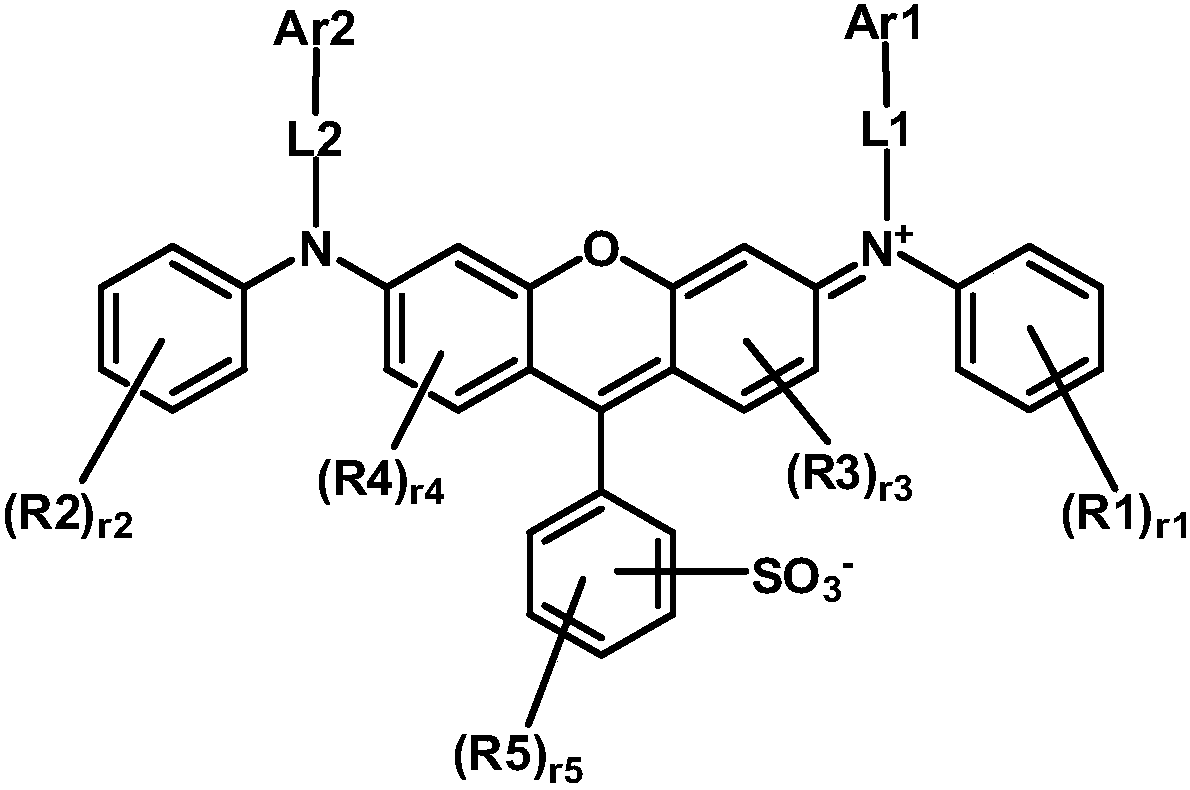

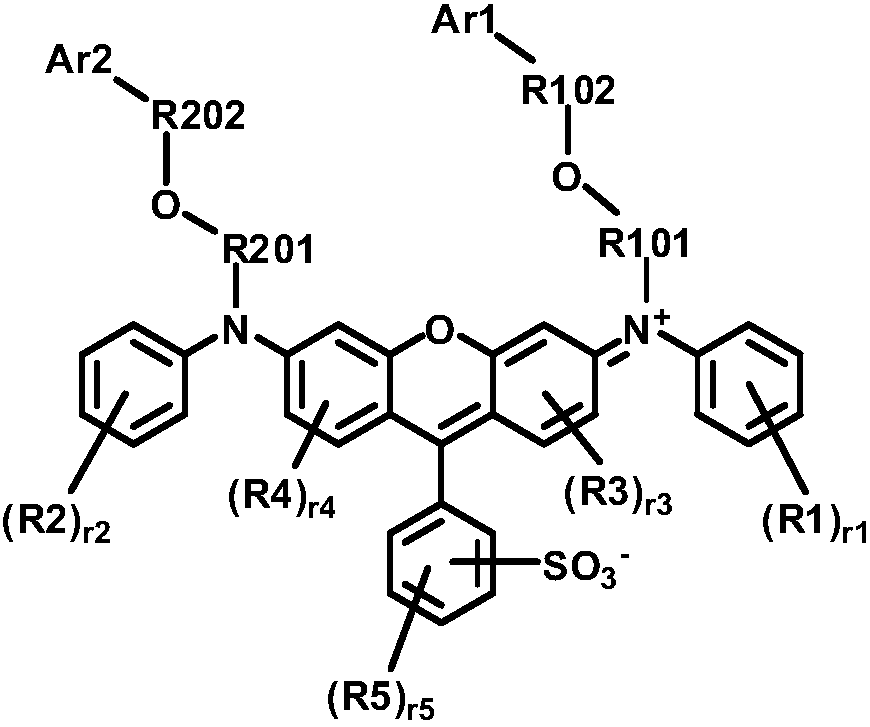

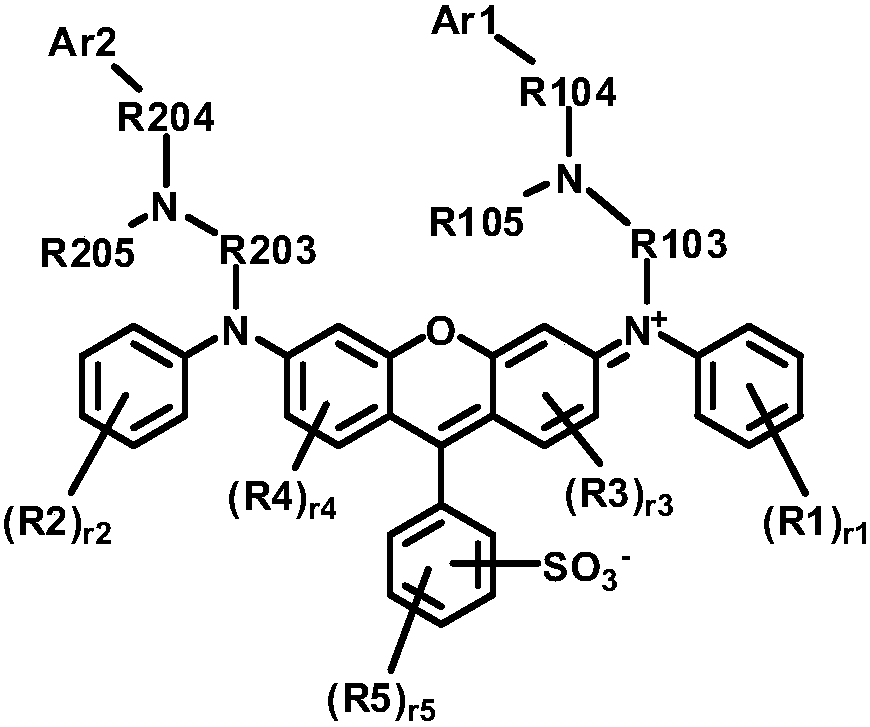

Image

Examples

manufacture example 1

[0202] Production Example 1. Production of Compound 1

[0203]

[0204] 11.59 g (15.23 mmol) of B-1 and 2.5 g (15.23 mmol) of A-1 were added to 700 g of pyridine, and stirred at room temperature for 24 hours. The reaction was added to DI water and stirred for 1 hour. Under reduced pressure, the precipitate was filtered, washed with water, and dried at 80° C. for 12 hours. Thereafter, compound 1 was obtained by subjecting the dried precipitate to column chromatography.

[0205] Ionization mode =: APCI+: m / z=928[M+H]+, Exact Mass: 927

manufacture example 2

[0206] Production Example 2. Production of Compound 2

[0207]

[0208] In the above-mentioned Production Example 1, except that C-1 was used instead of B-1, Compound 2 was produced in the same manner.

[0209]Ionization mode =: APCI+: m / z=984[M+H]+, Exact Mass: 983

manufacture example 3

[0210] Production Example 3. Production of Compound 3

[0211]

[0212] In the above-mentioned Production Example 1, except that D-1 was used instead of B-1, Compound 3 was produced in the same manner.

[0213] Ionization mode =: APCI+: m / z=1040[M+H]+, Exact Mass: 1039

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com