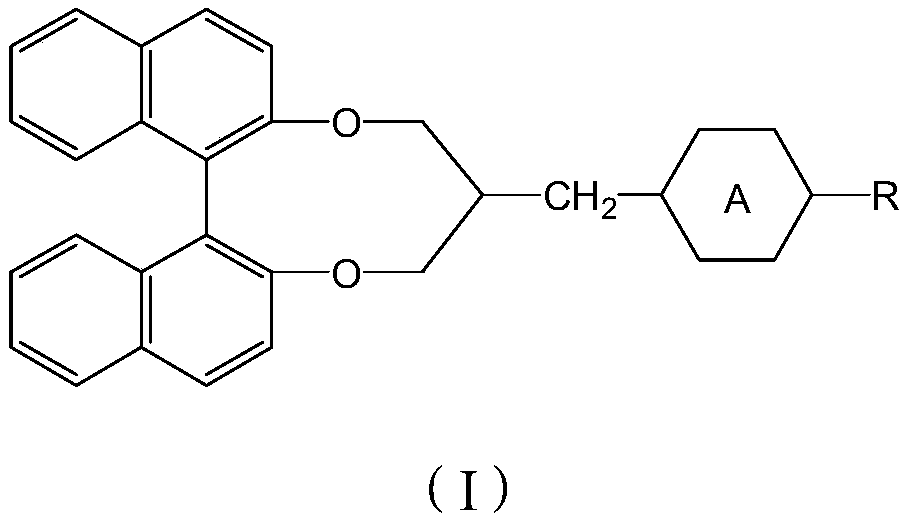

A kind of binaphthyl diol chiral compound and its preparation method and application

A chiral compound, binaphthol technology, applied in the field of liquid crystals, can solve problems such as low HTP value, poor solubility, easy crystal precipitation, etc., and achieve the effect of reducing negative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The structural formula of embodiment 1 chiral compound is:

[0050]

[0051] The synthetic route for preparing compound BYLC-01 is as follows:

[0052]

[0053] Specific steps are as follows:

[0054] (1) Synthesis of compound BYLC-01-1:

[0055] Add 44.8g of potassium tert-butoxide and 300ml of N,N-dimethylformamide into the reaction flask, control the temperature below 50°C, add 64g of diethyl malonate dropwise, and stir naturally for 1 hour. Control the temperature at 50°C to 60°C, add 69.6g of 4-n-propylcyclohexylmethyl chloride dropwise, and react at 60°C for 3 hours after dropping. The reaction was quenched with 300ml of 2M hydrochloric acid aqueous solution, followed by conventional post-treatment, and high vacuum and reduced pressure distillation to obtain 73.9g of a colorless transparent liquid (compound BYLC-01-1), GC: 96.7%, yield 62%;

[0056] (2) Synthesis of compound BYLC-01-2:

[0057]Under the protection of nitrogen, add 200ml tetrahydrofuran a...

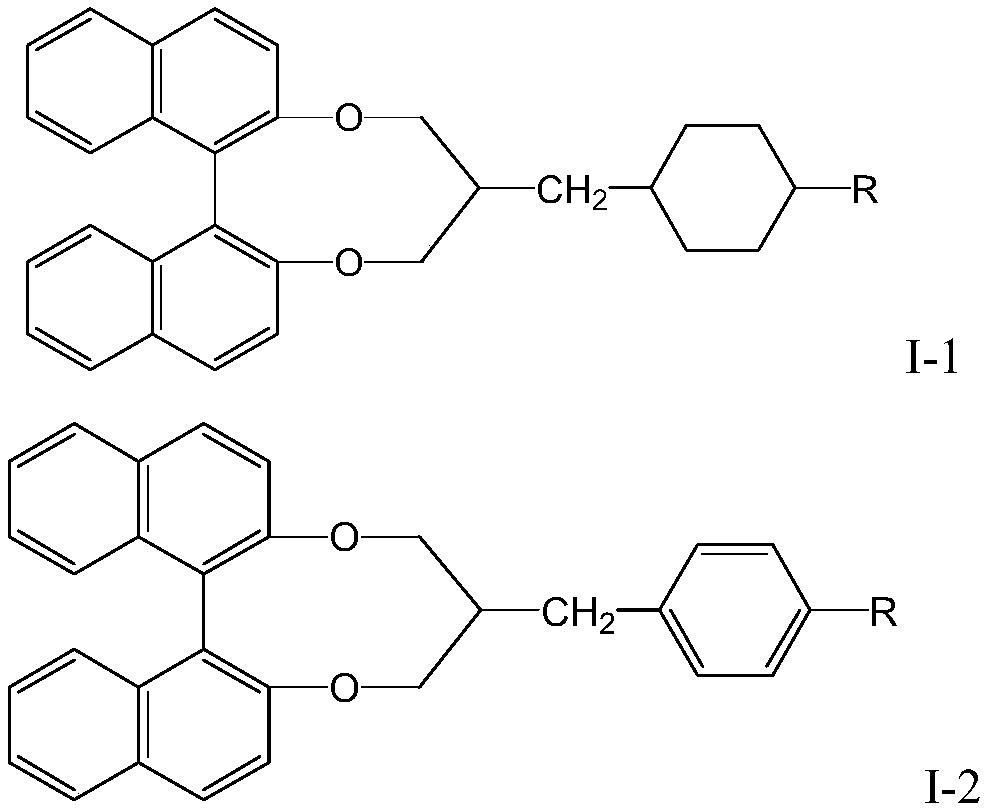

Embodiment 2

[0064] According to the technical scheme of Example 1, the following chiral compounds can be synthesized by simply replacing the corresponding raw materials without changing any substantive operations. The HTP value of each compound was detected by the same method as in Example 1, and the results showed that the HTP value was substantially the same as in Example 1.

[0065]

[0066]

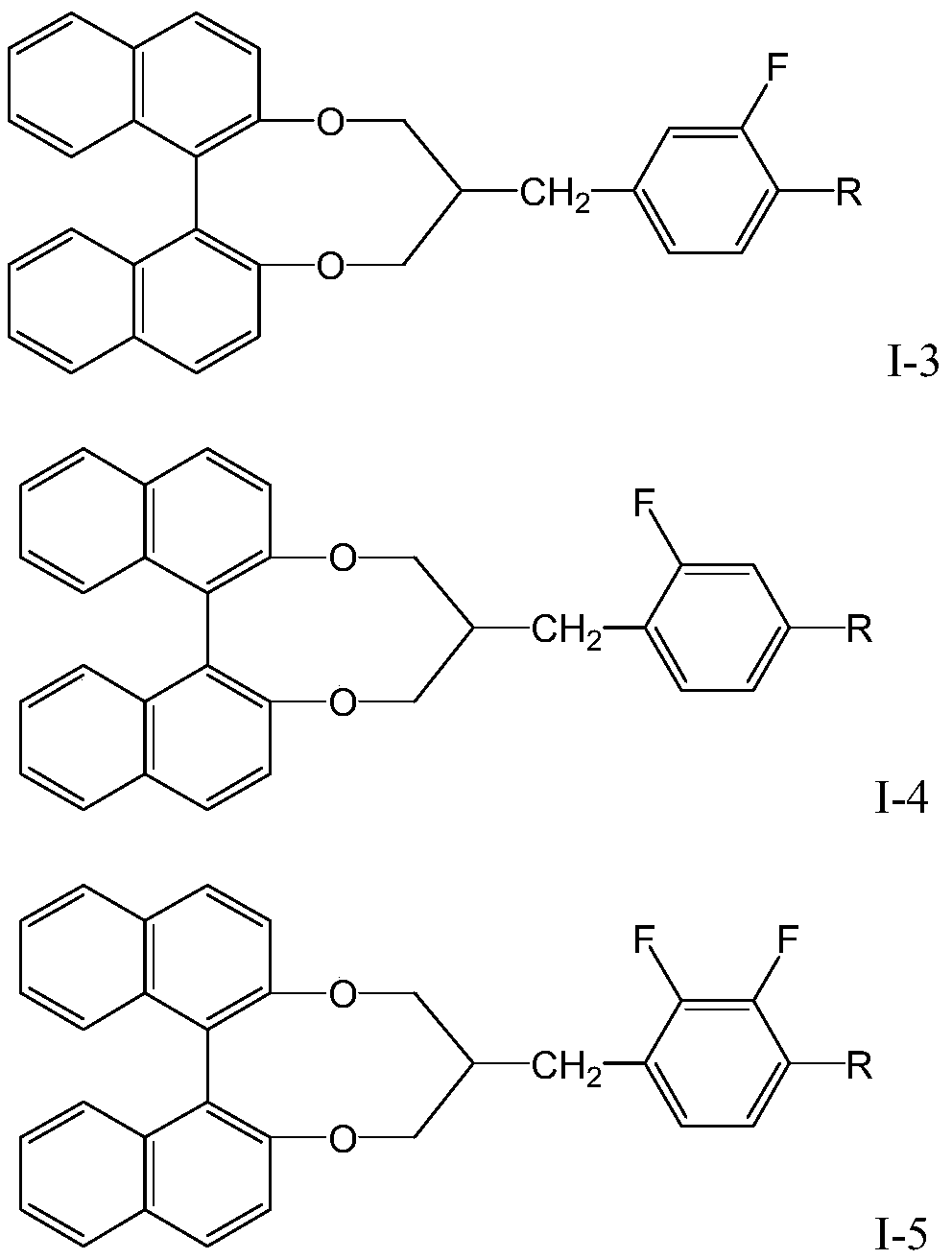

Embodiment 3

[0068] The structural formula of a chiral compound is:

[0069]

[0070] The synthetic route for preparing compound BYLC-03 is as follows:

[0071]

[0072] Specific steps are as follows:

[0073] (1) Synthesis of compound BYLC-03-1:

[0074] Add 44.8g of potassium tert-butoxide and 300ml of N,N-dimethylformamide into the reaction flask, control the temperature below 50°C, add 64g of diethyl malonate dropwise, and stir naturally for 1 hour. Control the temperature at 50°C to 60°C, add 82.4g of 3,4-difluorobenzyl bromide dropwise, and react at 60°C for 3 hours after dropping. Quench the reaction with 300ml of 2M hydrochloric acid aqueous solution, perform conventional post-treatment, and distill under high vacuum to obtain 75.5g of a colorless transparent liquid (compound BYLC-03-1), GC: 94.1%, yield 66%;

[0075] (2) Synthesis of compound BYLC-03-2:

[0076] Under the protection of nitrogen, add 300ml tetrahydrofuran and 9.6g lithium aluminum tetrahydrogen to the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com