Method for testing corrosion resistance of coating and application thereof

A technology of corrosion resistance and test method, applied in the direction of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve the problems of small acceleration magnification, unfavorable coating protection performance, long test period and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

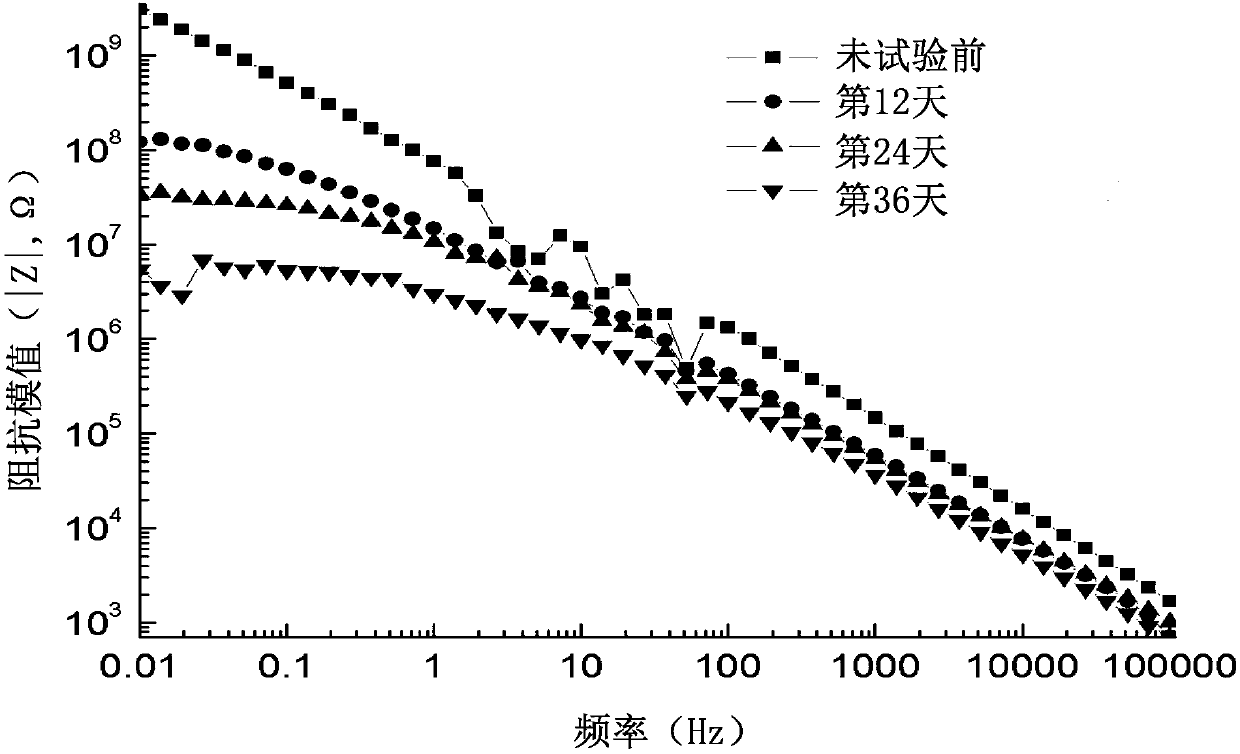

Embodiment 1

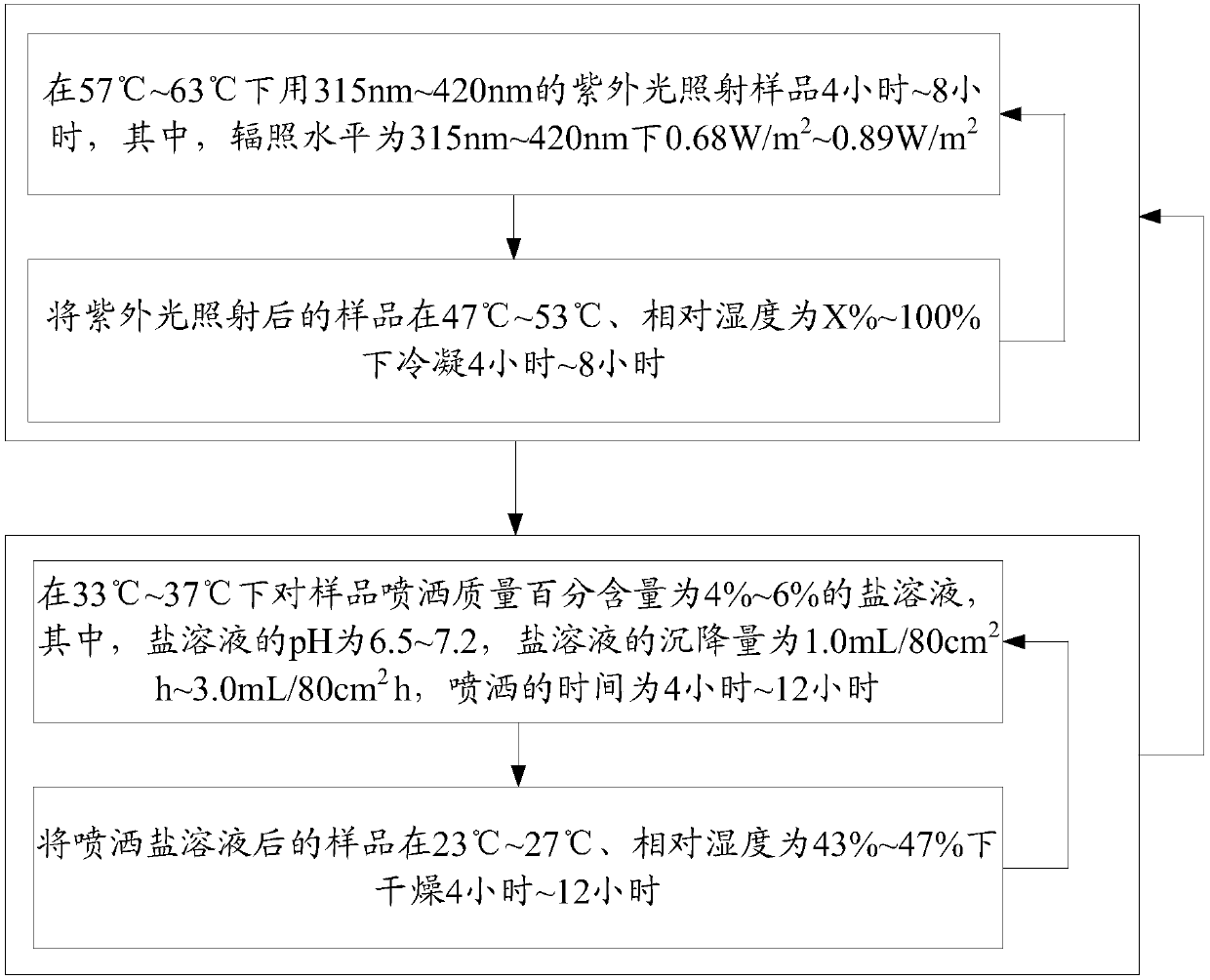

[0059] The specific process of the corrosion resistance test method of the coating of the present embodiment is as follows:

[0060] 1. Test object: The primer on the surface of the substrate is LS083 polyurethane, and the topcoat is H06-3 zinc yellow epoxy polyamide. Among them, the substrate is 2A12 aluminum plate, the dry film thickness of the primer is 20 μm, and the dry film thickness of the topcoat is 20 μm. 60 μm.

[0061] 2. Test arrangement: Alternately conduct UV aging test and salt spray test on the samples, and conduct the UV aging test and salt spray test 6 times each. The irradiation test and the condensation test were carried out 6 times each, and the salt spray test included alternately performing the salt spray test and the drying test on the samples, and the salt spray test and the drying test were carried out 3 times each.

[0062] 3. Specific operation of the test:

[0063] (1) The specific operation of the ultraviolet irradiation test is: at 63°C, the ir...

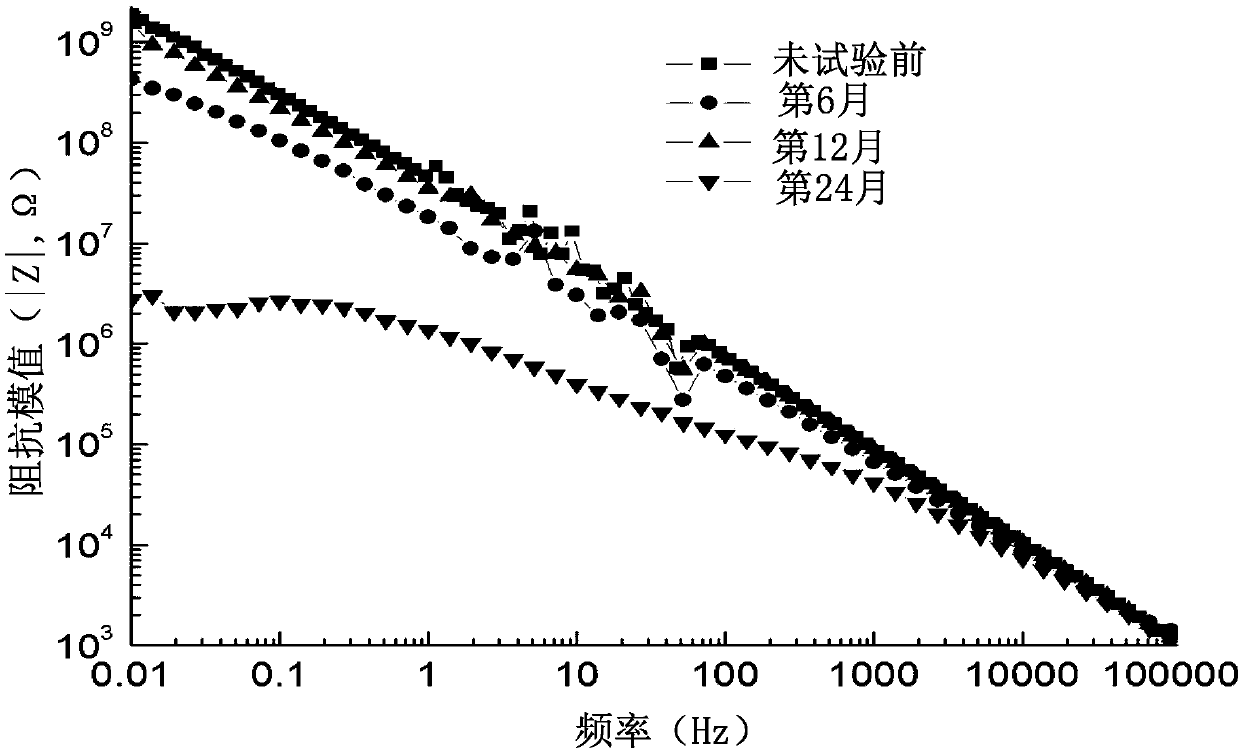

Embodiment 2

[0068] The specific process of the corrosion resistance test method of the coating of the present embodiment is as follows:

[0069] 1. Test object: The primer on the surface of the substrate is acrylic polyurethane, and the topcoat is a sample of fluorine-containing polyamide. Among them, the substrate is a 5A06 aluminum plate, the thickness of the primer is 20 μm, and the thickness of the topcoat is 50 μm.

[0070] 2. Test arrangement: Alternately conduct UV aging test and salt spray test on the samples, and conduct the UV aging test and salt spray test 6 times each. The irradiation test and the condensation test were carried out 6 times each, and the salt spray test included alternately performing the salt spray test and the drying test on the samples, and the salt spray test and the drying test were carried out 9 times each.

[0071] 3. Specific operation of the test:

[0072] (1) The specific operation of the ultraviolet irradiation test is: at 60°C, the irradiation leve...

Embodiment 3

[0077] The specific process of the corrosion resistance test method of the coating of the present embodiment is as follows:

[0078] 1. Test object: The primer on the surface of the substrate is iron red epoxy polyamide paint and the topcoat is polyurethane paint. Among them, the substrate is A3 steel plate, the thickness of the primer is 25 μm, and the thickness of the topcoat is 80 μm.

[0079]2. Test arrangement: Alternately conduct UV aging test and salt spray test on the samples, and conduct the UV aging test and salt spray test 6 times each. The irradiation test and the condensation test were carried out 6 times each, and the salt spray test included alternately performing the salt spray test and the drying test on the samples, and the salt spray test and the drying test were carried out 6 times each.

[0080] 3. Specific operation of the test:

[0081] (1) The specific operation of the ultraviolet irradiation test is: at 57°C, the irradiation level is 0.89W / m at 340nm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com