Magnesium alloy material with high corrosion resistance and preparation method of magnesium alloy material

A corrosion-resistant, magnesium alloy technology, applied in the field of high corrosion-resistant magnesium alloy materials and their preparation, can solve the problems of corrosion, magnesium alloy corrosion resistance is not too ideal, affecting the effect or life of the application, etc., to achieve a wide range of sources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

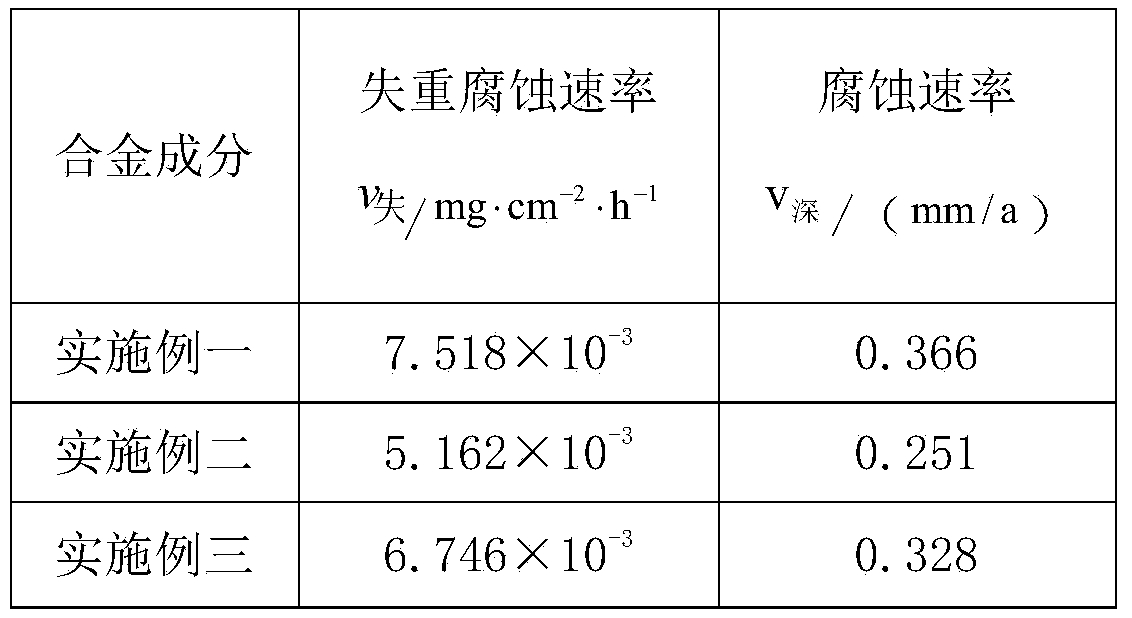

Embodiment 1

[0015] In this example, the composition and mass percentage of the high corrosion-resistant magnesium-aluminum alloy are: Al: 4.5%, Zn: 1.5%, Mn: 0.1%, Y: 0.1%; content of impurity elements: Fe: 0.008%, Ni: 0.001%, Cu: 0.0004%, Si: 0.02%, Ca: 0.0019%, and the balance is magnesium.

[0016] Weigh the material according to the ratio, preheat the pure magnesium ingot to 250°C and put it into a 45# steel crucible with a preheating temperature of 500°C to melt it, and pass it into SF 6 +CO 2 +N 2 Protective gas (mixed gas ratio / V%: 50N 2 +50CO 2 +0.3SF 6 ), and the temperature was raised to 700°C. After the magnesium ingot is completely melted, raise the temperature to 720°C, add pure aluminum preheated to 250°C, stir for 2-3 minutes after adding until it is completely melted, then follow the method of adding pure aluminum to keep the temperature at 720°C and add in sequence Pure zinc, Al-10%Mn master alloy, Mg-30%Y master alloy. After it is all melted, skim off the surface ...

Embodiment 2

[0018] In this example, the composition and mass percentage of the high corrosion-resistant magnesium-aluminum alloy are: Al: 5.0%, Zn: 1.8%, Mn: 0.2%, Y: 0.3%; content of impurity elements: Fe: 0.0063%, Ni: 0.0026%, Cu: 0.0004%, Si: 0.026%, Ca: 0.0023%, and the balance is magnesium.

[0019] Weigh the material according to the ratio, preheat the pure magnesium ingot to 250°C and put it into a 45# steel crucible with a preheating temperature of 500°C to melt it, and pass it into SF 6 +CO 2 +N 2 Protective gas (mixed gas ratio / V%: 50N 2 +50CO 2 +0.3SF 6 ), and the temperature was raised to 700°C. After the magnesium ingot is completely melted, raise the temperature to 720°C, add pure aluminum preheated to 250°C, stir for 2-3 minutes after adding until it is completely melted, then follow the method of adding pure aluminum to keep the temperature at 720°C and add in sequence Pure zinc, Al-10%Mn master alloy, Mg-30%Y master alloy. After it is all melted, skim off the surfa...

Embodiment 3

[0021] In this example, the composition and mass percentage of the high corrosion-resistant magnesium-aluminum alloy are: Al: 5.5%, Zn: 2.0%, Mn: 0.3%, Y: 0.5%; content of impurity elements: Fe: 0.0033%, Ni: 0.0011%, Cu<0.0004%, Si: 0.013%, Ca: 0.0020%, and the balance is magnesium.

[0022] Weigh the material according to the ratio, preheat the pure magnesium ingot to 250°C and put it into a 45# steel crucible with a preheating temperature of 500°C to melt it, and pass it into SF 6 +CO 2 +N 2 Protective gas (mixed gas ratio / V%: 50N 2 +50CO 2 +0.3SF 6 ), and the temperature was raised to 700°C. After the magnesium ingot is completely melted, raise the temperature to 720°C, add pure aluminum preheated to 250°C, stir for 2-3 minutes after adding until it is completely melted, then follow the method of adding pure aluminum to keep the temperature at 720°C and add in sequence Pure zinc, Al-10%Mn master alloy, Mg-30%Y master alloy. After it is all melted, skim off the surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com