Intelligent fully-mechanized coal mining face spray control system based on wireless sensor

A wireless sensor and fully mechanized mining face technology, applied in the field of machinery, can solve the problems of short dust-proof cycle intervals, inability to effectively prevent dust accumulation, and not cure the root cause, and achieve the effect of improving the level of refined management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with drawings and embodiments.

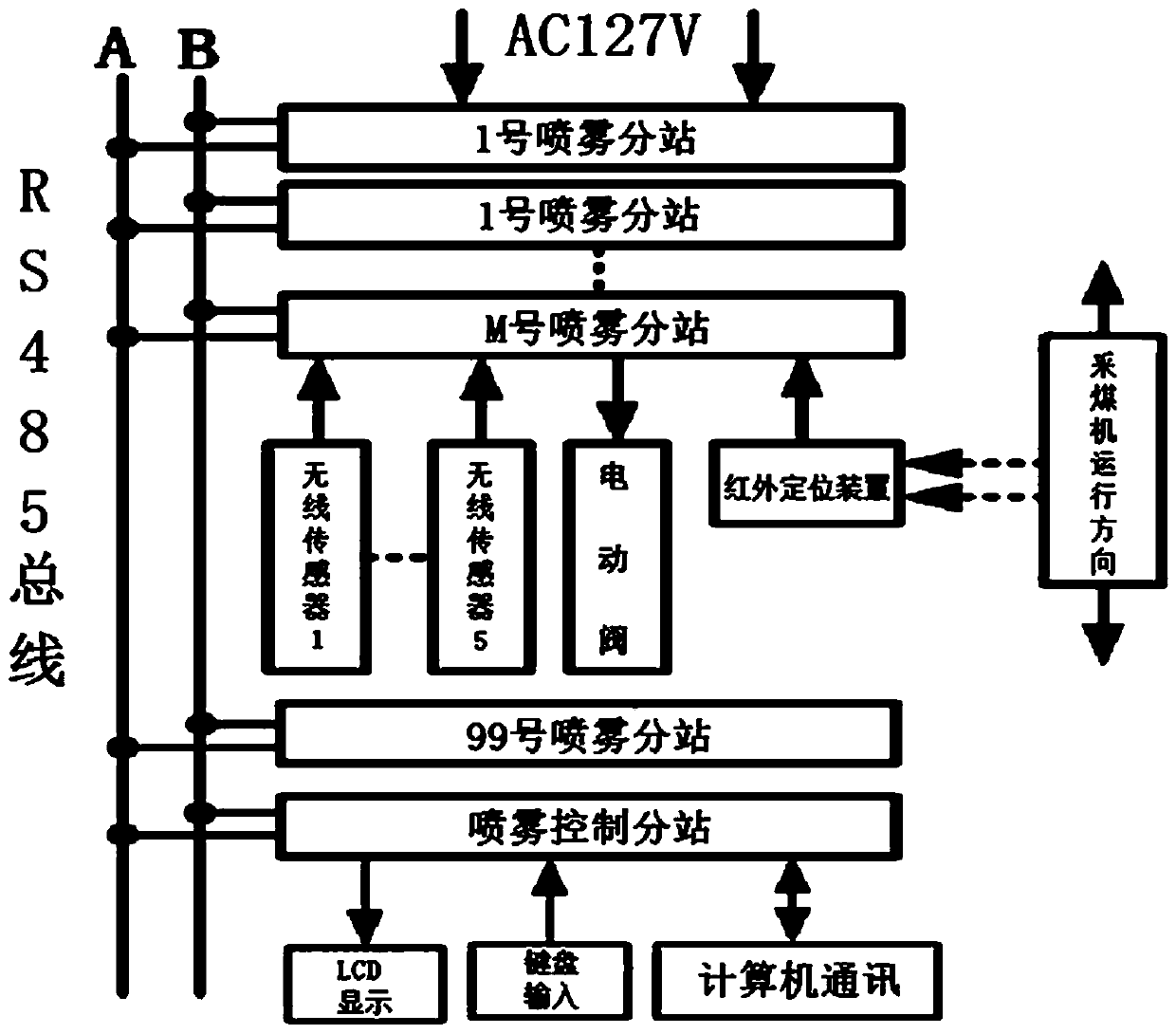

[0015] Such as figure 1 , The composition of the control system is divided into four parts from the physical structure: wireless sensor end, wireless collector end (substation), host computer and computer end. The four parts are closely connected; the combination of the four provides a powerful spray scheduling function, which can be set up for on-site needs to achieve the optimal spray dust reduction mode.

[0016] The spray master station uses dual single-chip microcomputers to work. The first single-chip microcomputer with dual serial ports STCI2CSA60S2 is responsible for collecting the data of the downlink spray sub-station, displaying the running status and settings, and storing the downlink data in the dual-port RAM. The second single-chip microcomputer STC11L16 The downlink data collection in RAM is transmitted to the computer. The system adopts 64K dual-port R...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap