Power battery cooling plate and cooling device

A cooling plate and power technology, applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problems of safety accidents, burning, damage to batteries, etc., and achieve the effects of not easy to leak, less parts, and sufficient heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

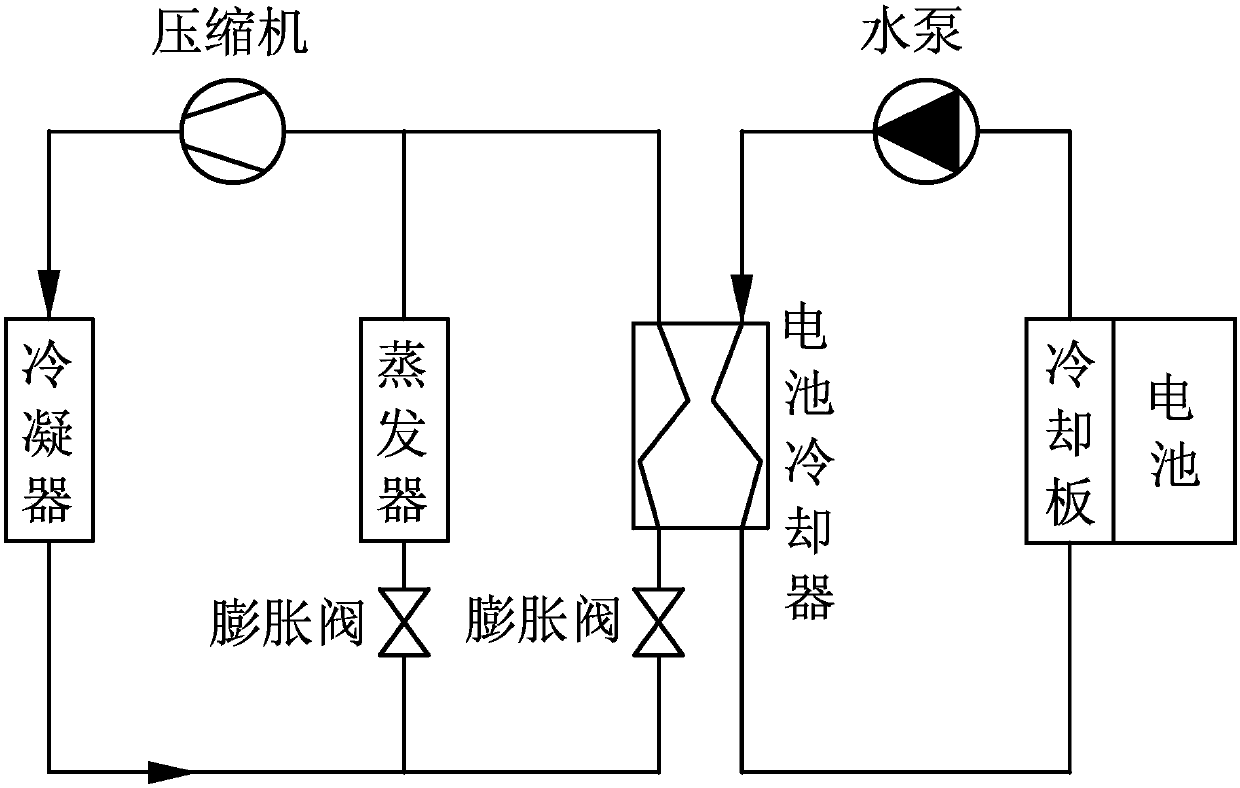

[0032] refer to figure 1 , the battery cooling device in the prior art has a refrigerant circuit and a cooling liquid circuit, the defects of which have been described above and will not be repeated here.

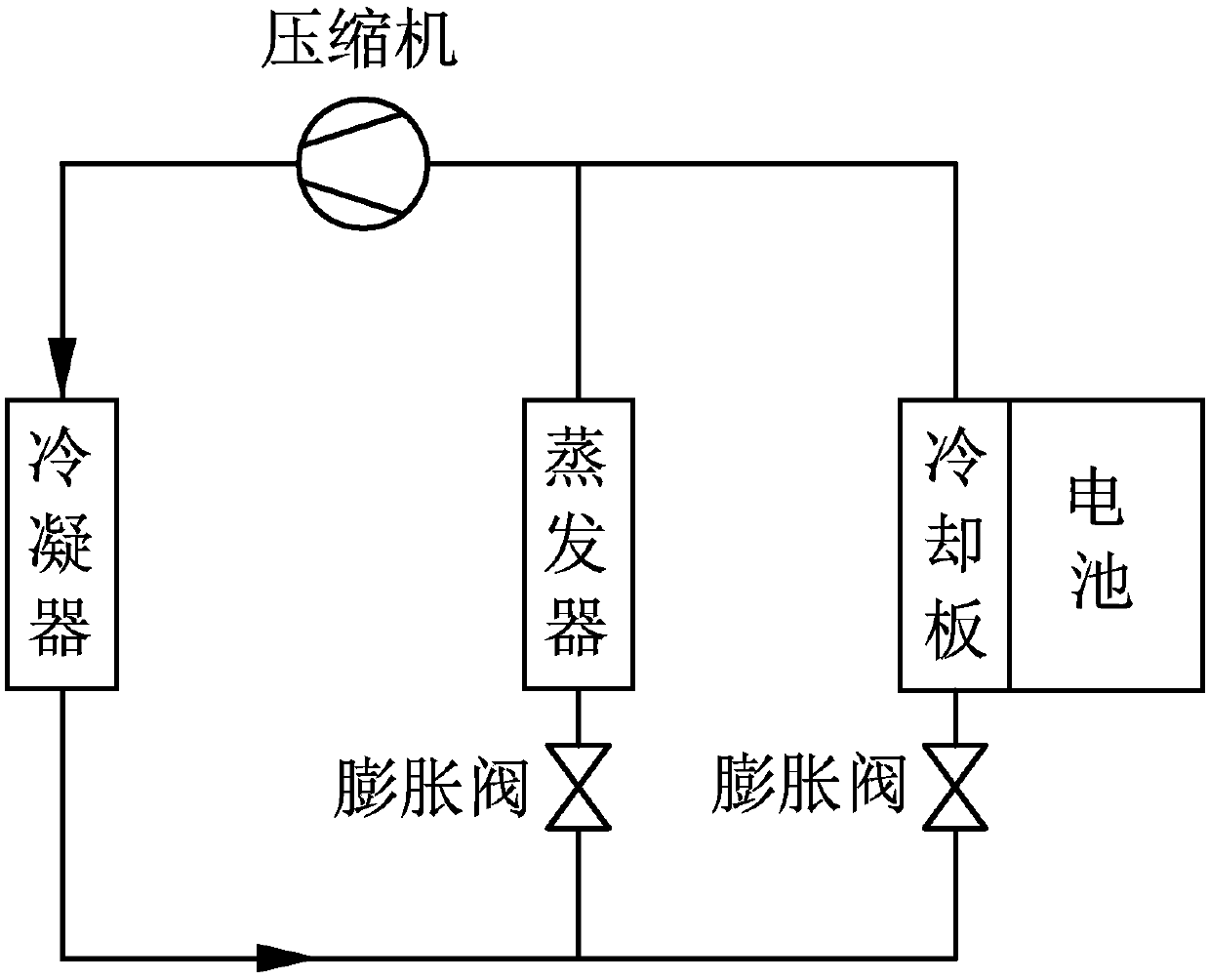

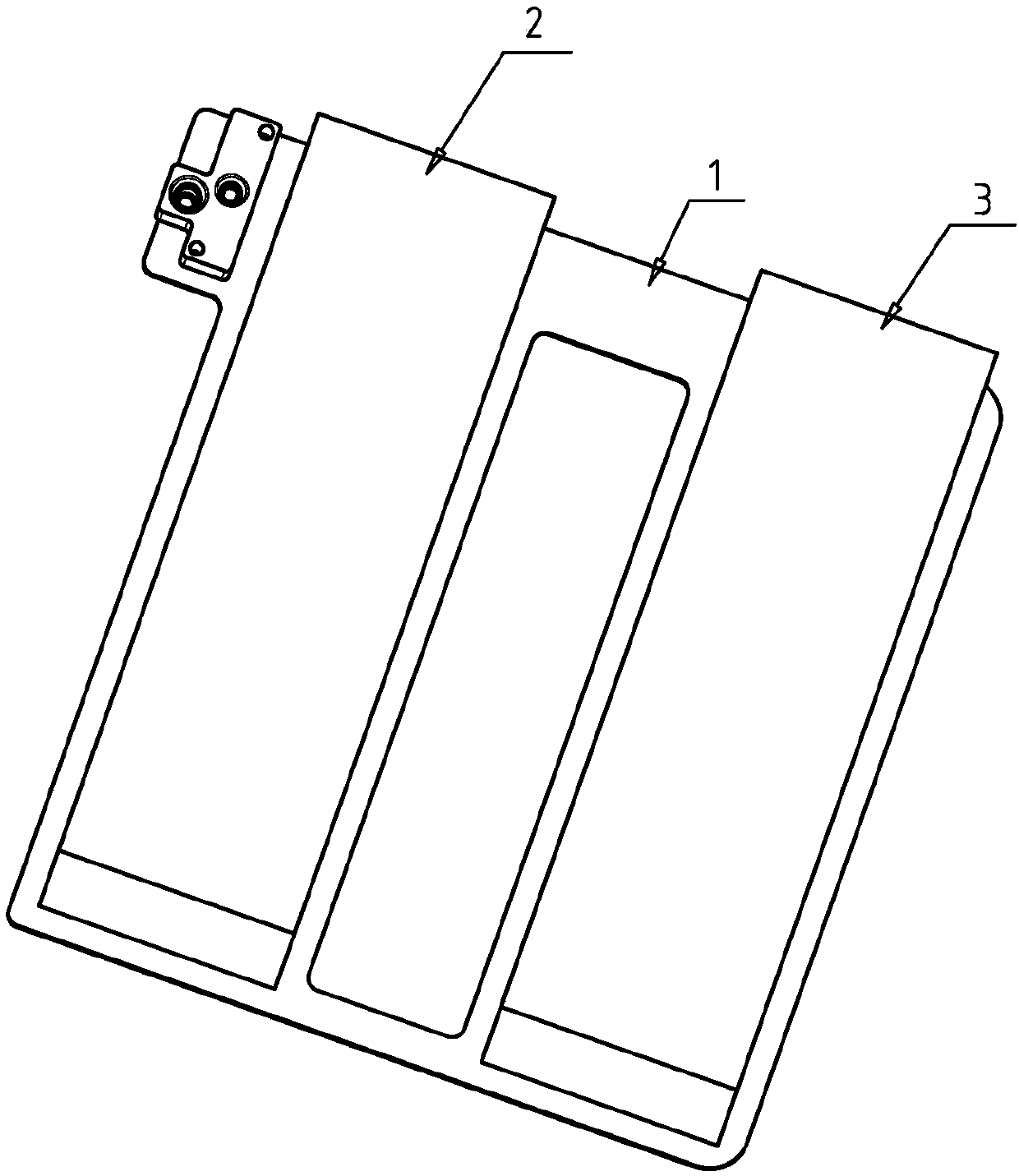

[0033] refer to figure 2 , a kind of power lithium battery cooling device of the present invention, comprises the second branch circuit that is made of cooling plate and the second expansion valve at the front end of cooling plate, described second branch circuit and the evaporator of automobile refrigeration system and the evaporator The first branch formed by the first expansion valve at the front end is connected in parallel, and the cooling plate is attached to the battery.

[0034] In the cooling device of a power lithium battery of the present invention, the liquid refrigerant coming out of the condenser is divided into two paths: one path enters the evaporator after throttling and depressurizing through the first expansion valve, where it vaporizes and absorbs heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com