Horizontal motor

A technology of horizontal motor and motor shaft, which is applied in the direction of electrical components, electromechanical devices, electric components, etc. It can solve the problems affecting the service life and performance of the motor, the motor is not equipped with a waterproof structure, and enters the inside of the motor, so as to facilitate disassembly and assembly. The effect of controlling production, avoiding adverse effects, and meeting waterproof requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

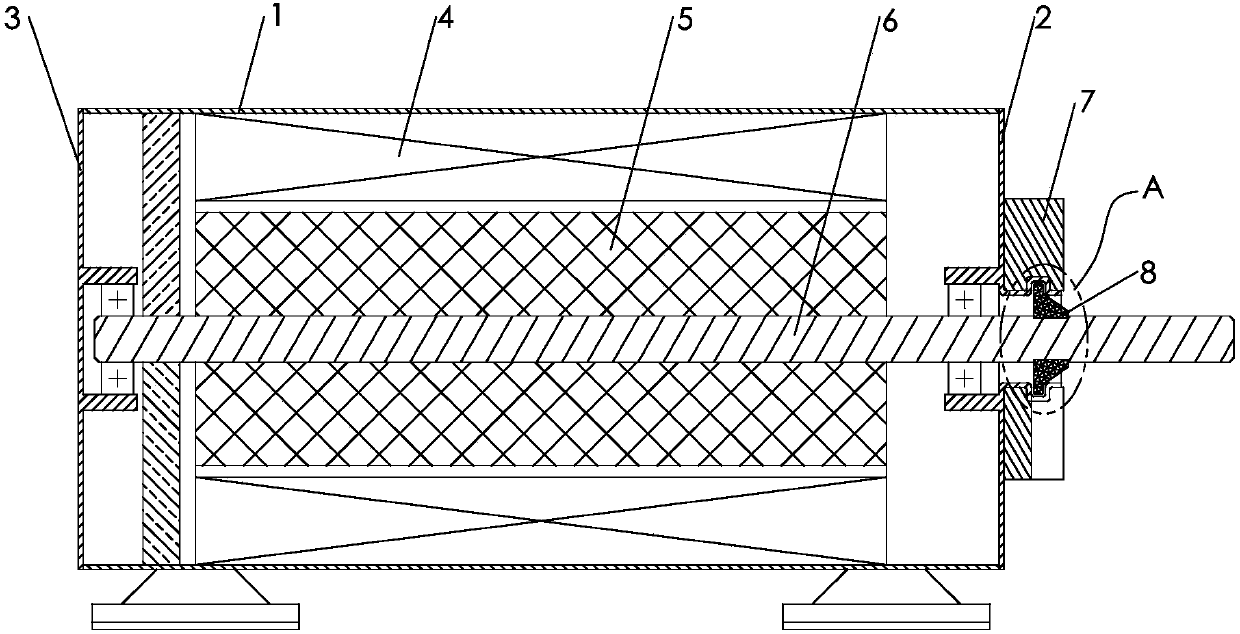

[0027] Such as figure 1 , figure 2 As shown, the transverse motor provided by Embodiment 1 of the present invention includes a casing 1, a front cover 2 arranged at the front end of the casing, a rear end cover 3 arranged at the rear end of the casing, a stator 4 arranged inside the casing, and a The rotor 5 and the motor shaft 6 arranged at the center of the rotor, the motor shaft is arranged horizontally, and the rotor 5 drives the motor shaft 6 to rotate under the action of the stator 4 to realize power output.

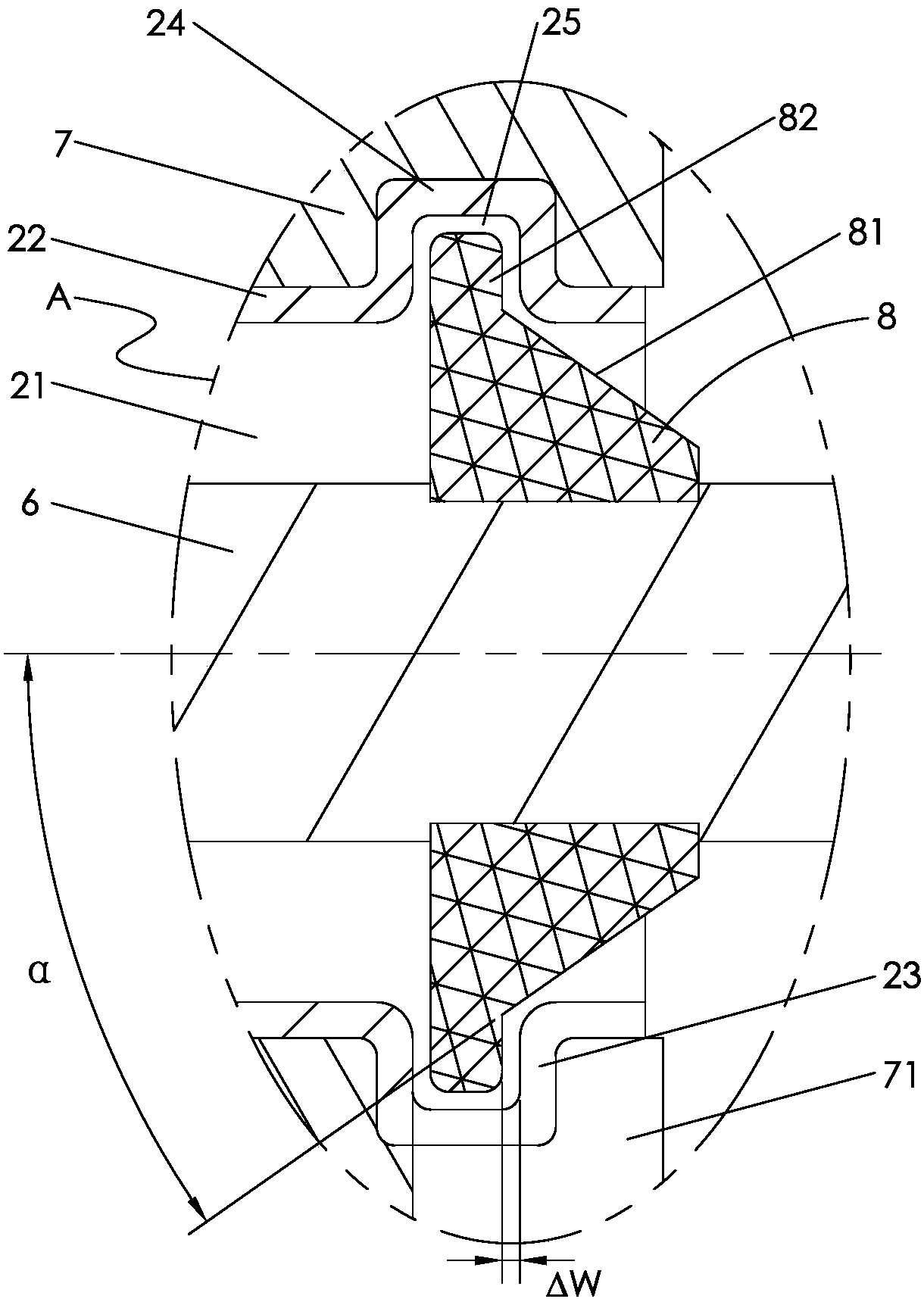

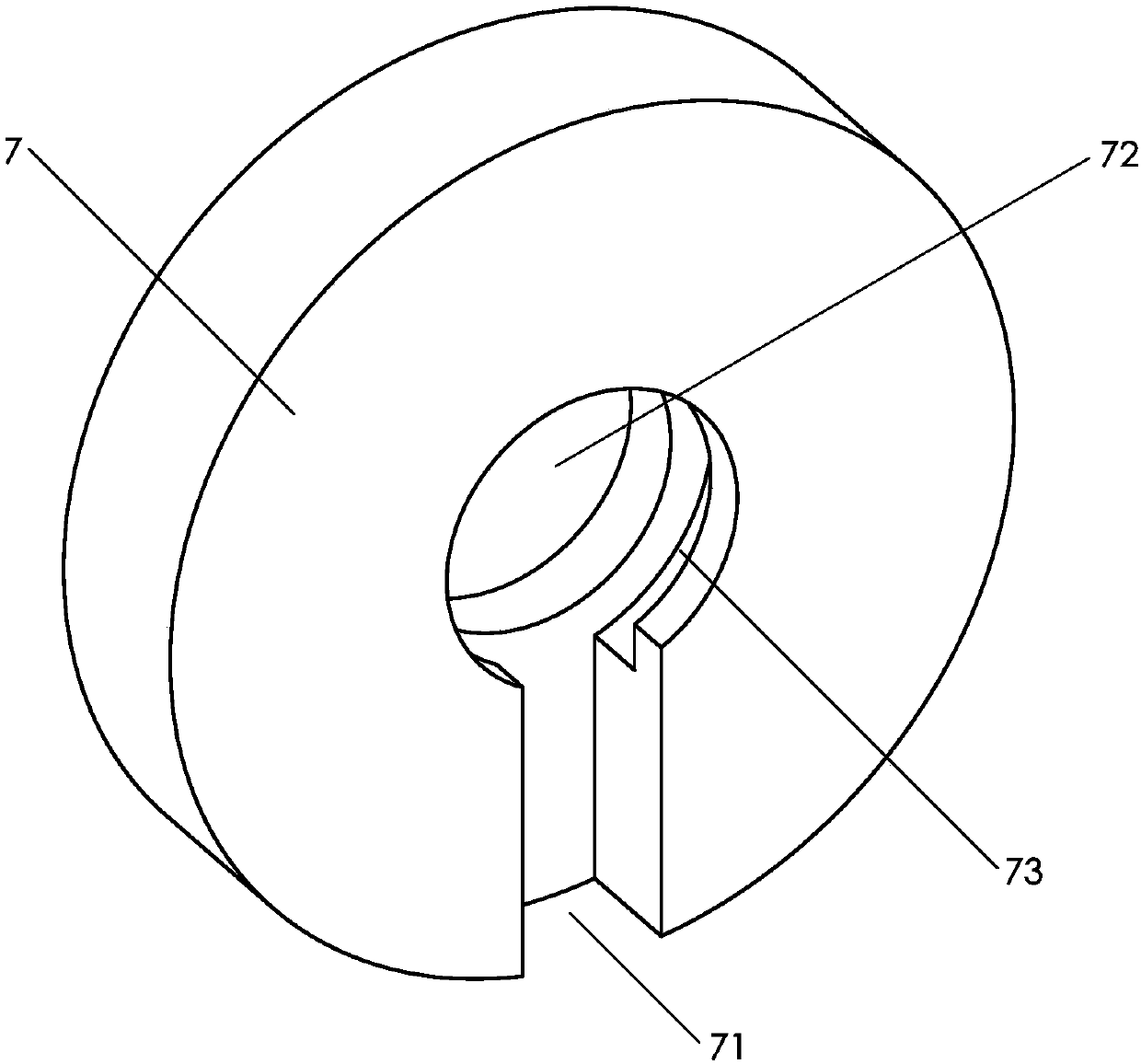

[0028] The center of the front end cover 2 is provided with a shaft hole 21 through which the power supply shaft 6 protrudes from the housing. The front end surface of the front end cover 2 is provided with an annular boss 22 protruding forward around the shaft hole. The annular boss is sleeved with Elastic shockproof ring 7. The front end of the motor shaft 6 is covered with an elastic waterproof ring 8 , the waterproof ring is accommodated in the shaft hole 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com