Disc type axial magnetic flux electric motor

An axial magnetic flux and motor technology, applied in the field of electric motors, can solve the problems of the failure of further development of axial permanent magnet motors, low utilization rate of iron cores, low power density, etc., to improve power, improve product performance, improve The effect of power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

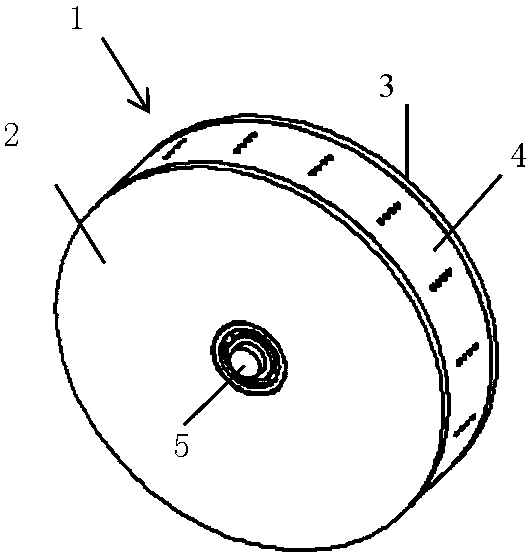

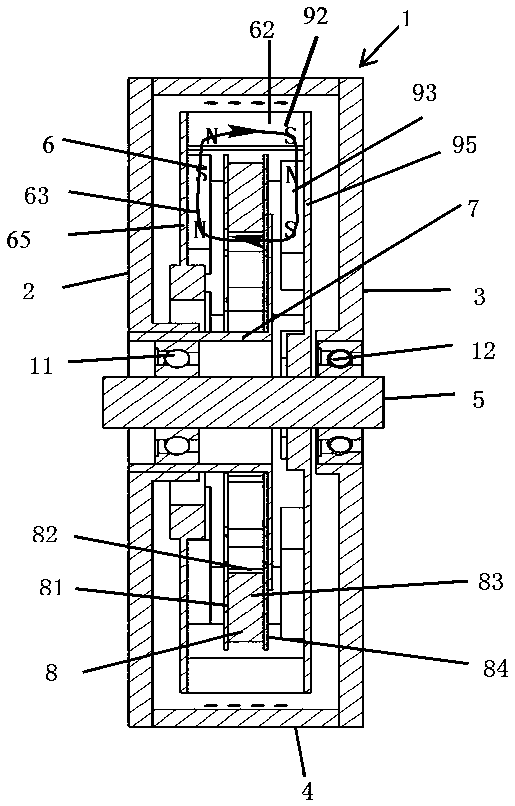

[0038] see figure 1 and figure 2 , a disk-type axial flux motor includes an annular casing 4, a stator 8, a first rotor 6, a second rotor 9 and a rotating shaft 5; the rotating shaft 5 passes through the axial middle of the stator 8, and the two ends rotate at The casing 4 , the first rotor 6 , and the second rotor 9 are mirror-symmetrically arranged on the rotating shaft 5 on both sides of the stator 8 and rotate with the rotating shaft 5 .

[0039] The specific structural improvements are as follows:

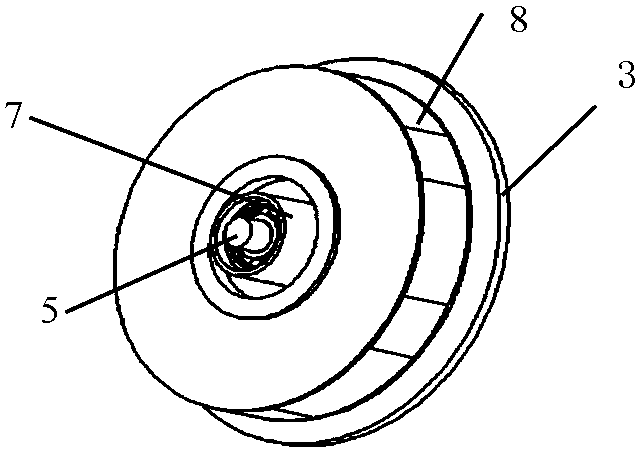

[0040] see Figure 6 , the stator 8 is a segmented structure without a yoke and consists of twelve stator units. Each stator unit includes a stator core 82 , which is a fan-shaped flat block; the first pole piece 81 and the second pole piece 84 have the same shape and are both fan-shaped. The first pole piece 81 and the second pole piece 84 are installed on both axial sides of the stator core 82 respectively, and the coil winding 83 is wound on the stator core 82 . Among...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com