A kind of potato bubble processing method with stable transmission

A processing method and stable technology, applied in food science and other directions, can solve the problem of ineffectiveness of soft conveyor belts, and achieve the effects of high quality, aroma and nutrients, and unique taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

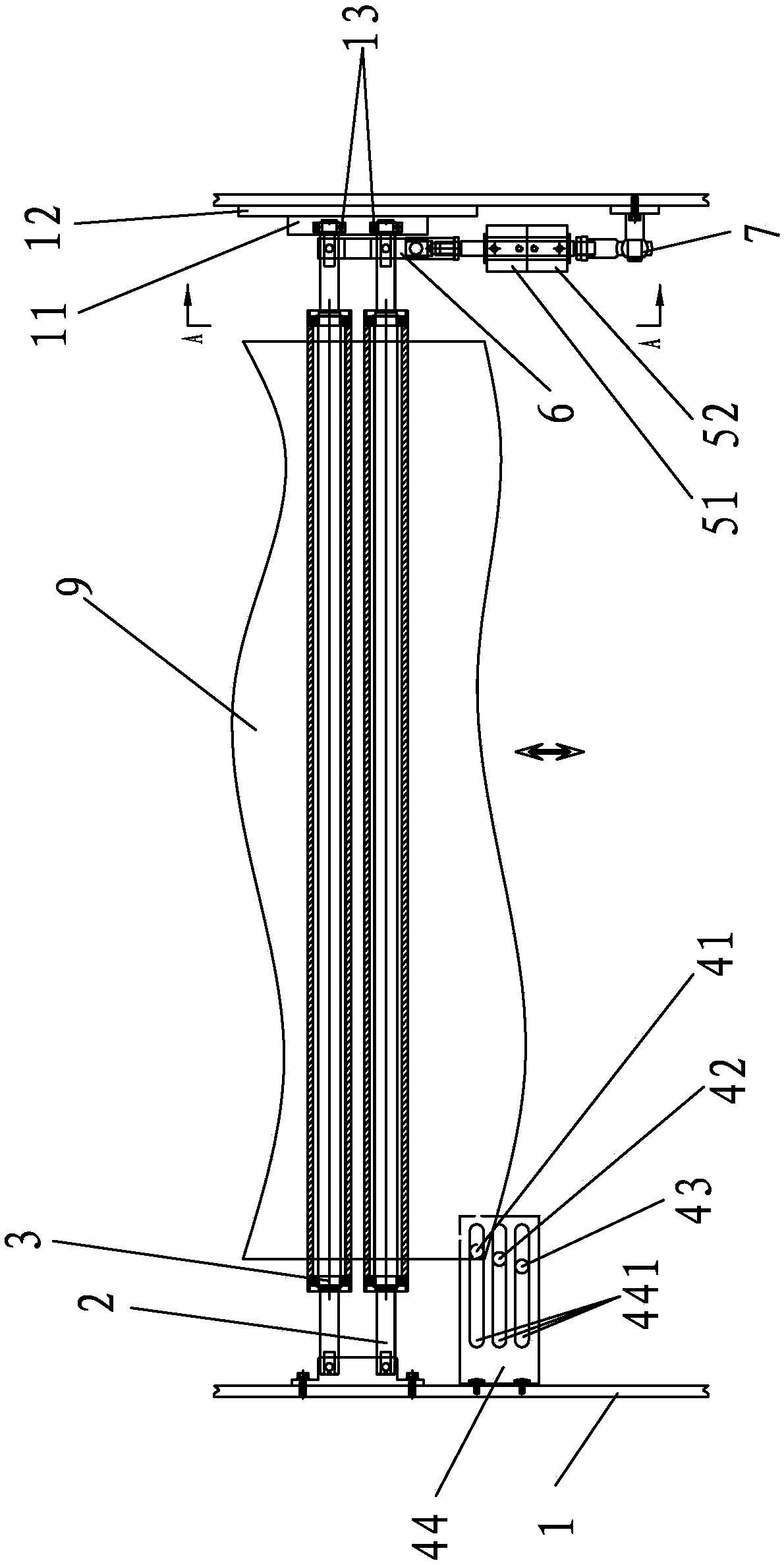

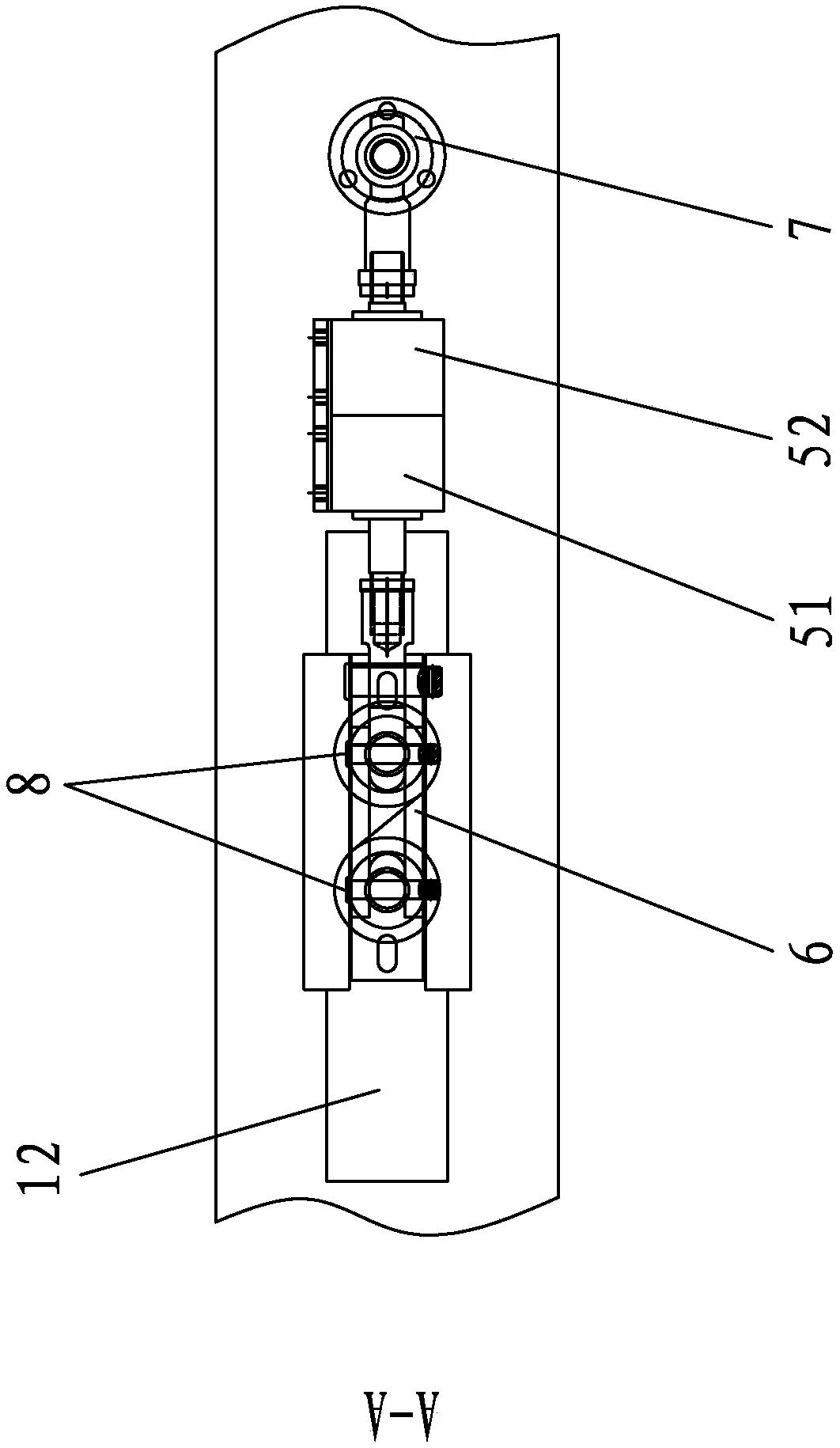

Image

Examples

Embodiment Construction

[0042] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

[0043] A kind of transmission stable potato bubble processing method of the present invention comprises the following steps:

[0044] (1) Raw material preparation: Prepare the following raw materials in parts by weight: 30 parts of whole potato powder, 20 parts of potato pregelatinized starch, 15 parts of potato starch, 12 parts of white granulated sugar, 12 parts of vegetable oil, 0.3 parts of lecithin, 1.5 parts of sesame paste , 0.6 parts of ammonium bicarbonate, 1.1 parts of table salt, 0.3 parts of spices and 43 parts of purified water;

[0045](2) Mixing powder: Put potato powder, potato pregelatinized starch, potato starch, white sugar, vegetable oil, lecithin, sesame paste, ammonium bicarbonate, salt, spices and purified water into the material barrel, and use a vertical mixer Stir the raw materials in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com