Freight station

A platform and cargo technology, applied in stations, transportation and packaging, railway car body parts, etc., can solve the problems of congestion on both sides of the waiting room track, high construction and maintenance costs, poor cargo loading and unloading efficiency, etc., to reduce safety hazards, The effect of reducing floor space and improving loading and unloading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The rail transit platform of the present invention is mainly used for rail transportation of personnel and goods.

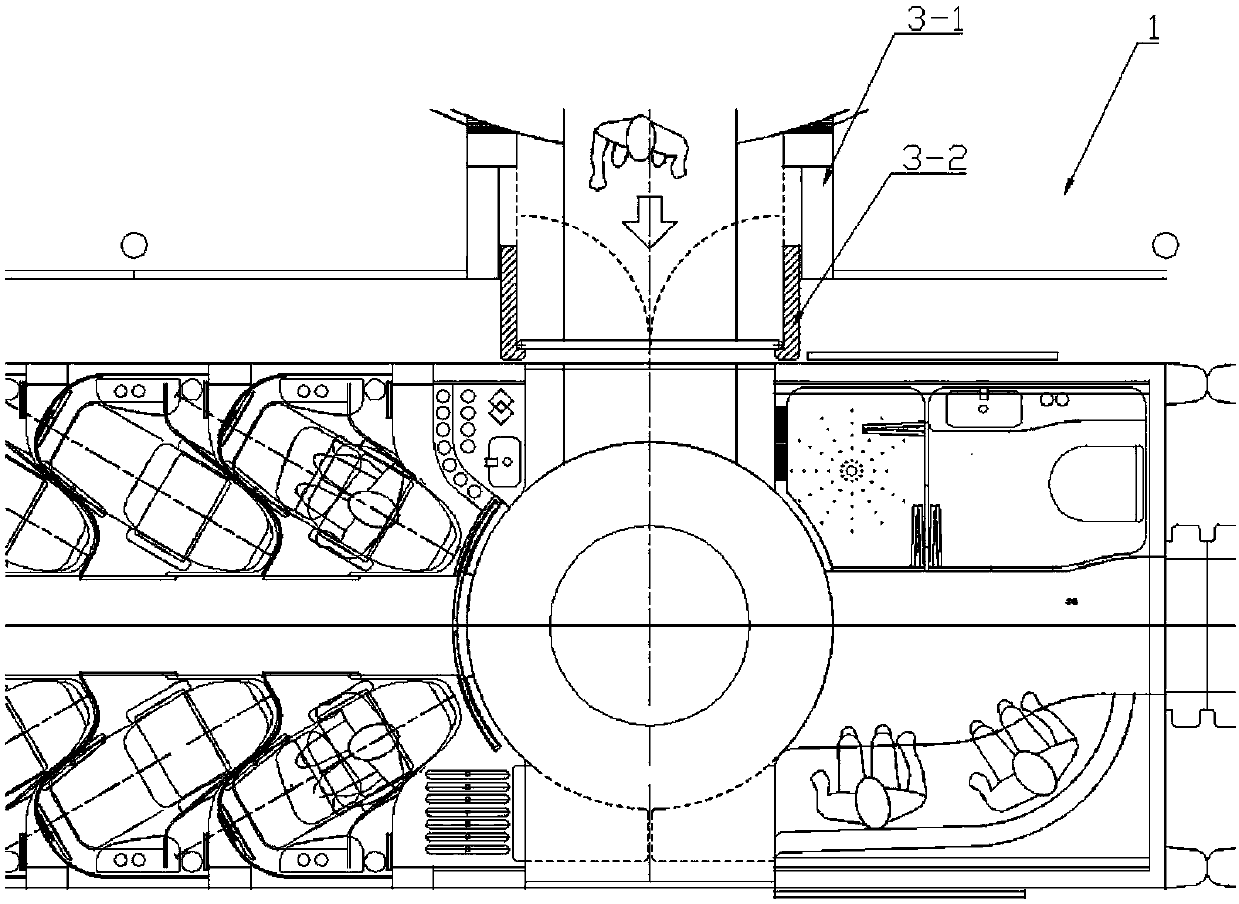

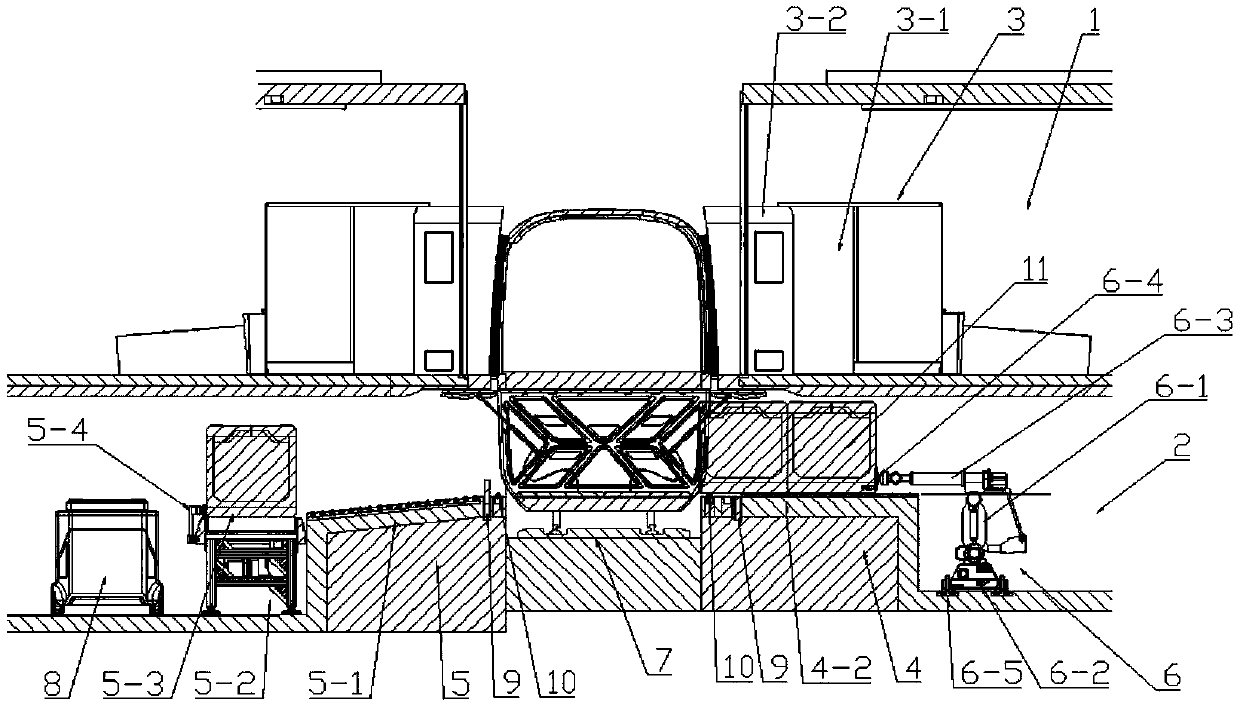

[0036] Such as Figures 2 to 4 Shown, a kind of rail transit platform comprises two layers of platforms, including the first layer platform at the bottom and the second layer platform at the top, wherein the first layer platform is freight layer 2, and the second layer platform is passenger layer 1, or all The first layer of platform is passenger layer 1, and the second layer of platform is freight layer 2.

[0037] Passenger layer 1 is used for passengers getting on and off, and freight layer 2 is used for loading and unloading goods, both of which are separate and can be carried out simultaneously. The freight layer 2 is provided with a warehouse 13 for collection and distribution of goods. Passenger layer 1 can be provided with a waiting room, and passengers can get on and off directly from the waiting room.

[0038] The present invention is provided...

Embodiment 2

[0041] In this embodiment, a rail transit platform includes a two-layer platform, including a first-layer platform at the bottom and a second-layer platform at the top, both of which are passenger layer 1 or freight layer 2 .

Embodiment 3

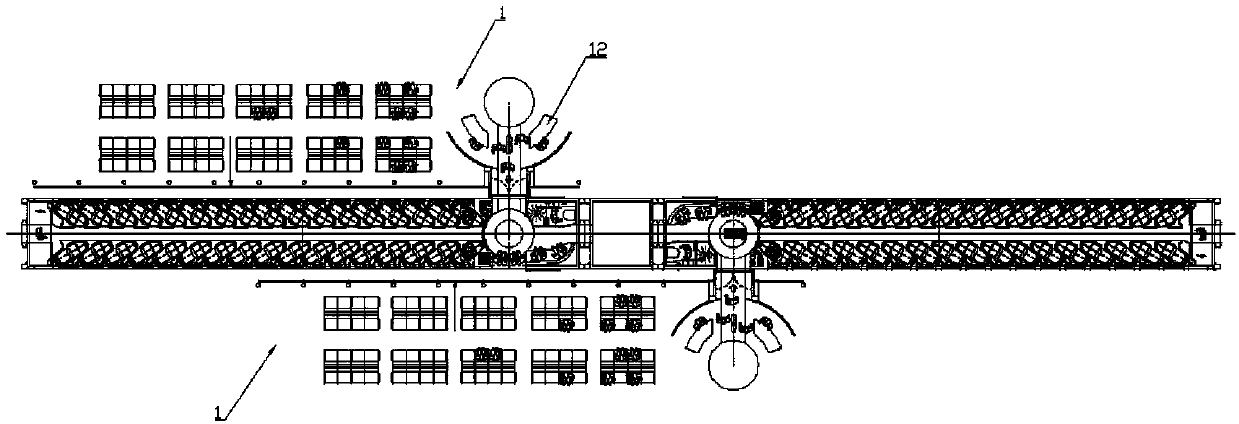

[0043] Such as image 3 , 4 As shown, in the present embodiment, the passenger layer 1 and the freight layer 2 of the rail transit platform are arranged on both sides of the train track 7, and the passenger layer 1 and the freight layer 2 extend to the track 7 and are adjacent to the train.

[0044] Passenger layer 1 is provided with a waiting room, and a ticket gate 12 is set in the waiting room. A connecting passage 3 is set between the passenger layer 1 and the train. Passengers can enter the connecting passage 3 through the ticket gate 12 to the train, and passengers in the train can also enter through the connecting passage 3. platform.

[0045] Passenger layer 1 extends to track 7 or next to the train. Passengers can get on and off the train directly in the waiting hall of passenger layer 1 without having to walk a long distance, which greatly facilitates passengers and can also reduce or avoid congestion caused when there are many people. , to reduce potential safety ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com