Hatch cover with ceramic layer

A ceramic layer and hatch cover technology, which is applied in the hatch cover field, can solve problems such as not meeting its requirements, and achieve the effect of preventing corrosion and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

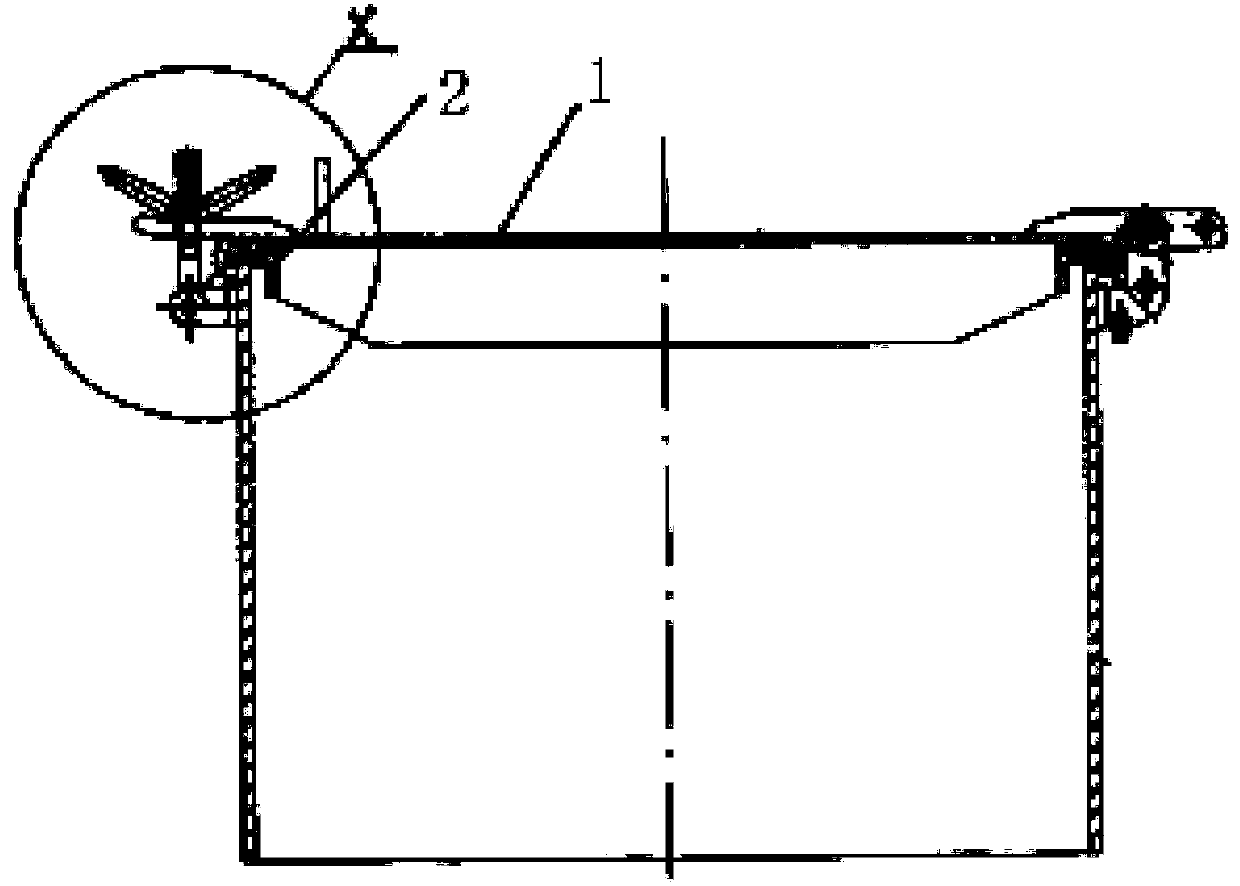

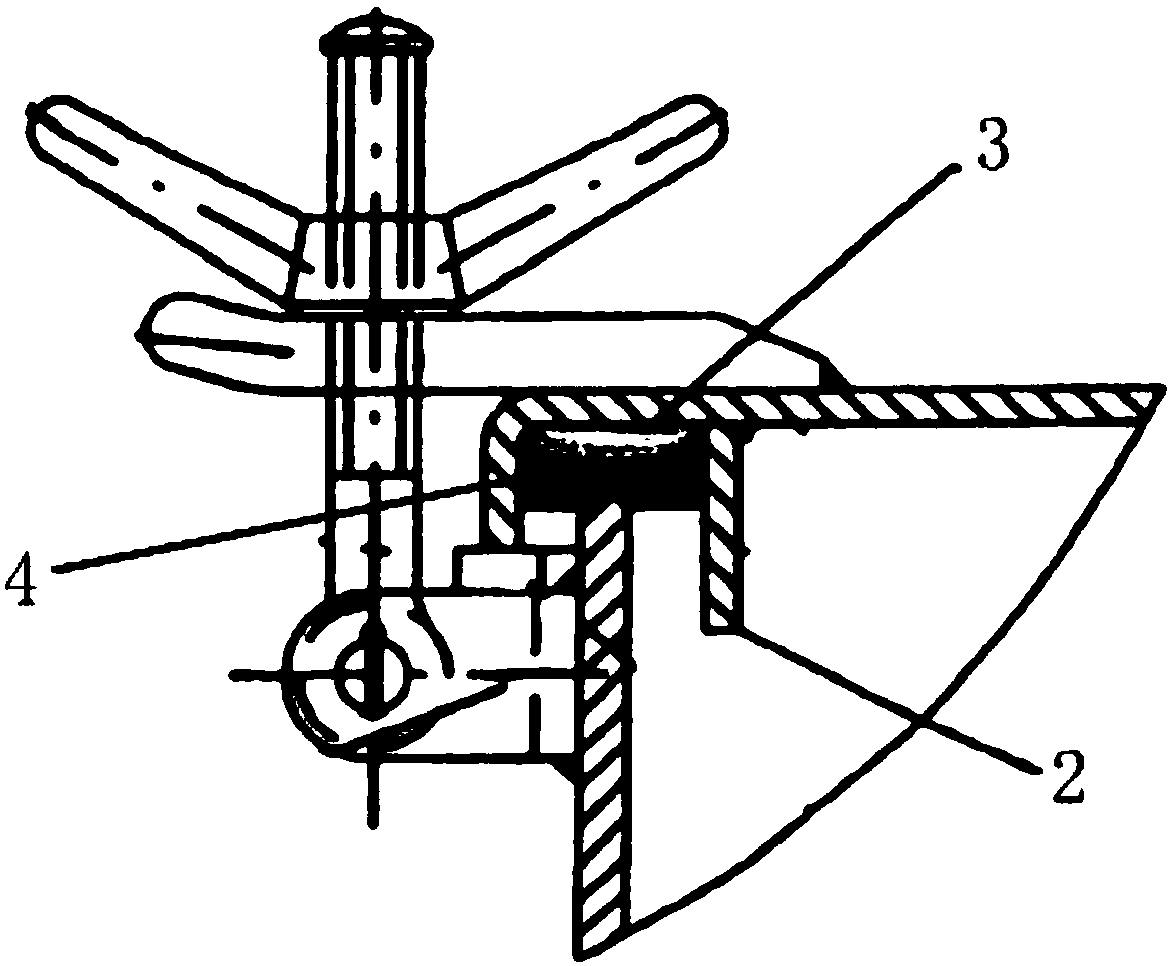

[0011] A hatch cover with a ceramic layer in this embodiment includes a cover plate 1, a coaming plate and a plurality of locking devices, the locking devices are used to tightly close the hatch cover, and the bottom surface of the cover plate 1 A retaining ring 2 is fixed on the top, the retaining ring 2 forms a frame structure together with the cover plate 1 by welding more than one reinforcing rib, a sealing ring 4 is arranged between the retaining ring 2 and the folded edge of the cover plate 1, and the cover plate 1 and the A ceramic layer 3 is arranged between the sealing rings 4, and the ceramic layer 3 protrudes toward the sealing ring 4 in an arc shape; the ceramic layer includes refractory ceramic fibers or biosoluble inorganic fibers; a viscosity modifier; a colloidal inorganic oxides; inorganic binders; inorganic particulates; and, glass fibers, leached silica fibers, high alumina fibers, mullite fibers, magnesium aluminosilicate fibers, S-2 fibers, basalt fibers, o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com