An inner packing line equipment for abdominal dialysis fluid

A dialysate and inner packaging technology, applied in the field of machinery and equipment, can solve the problems of increased labor costs, difficulty for workers, and reduced efficiency of abdominal dialysate packaging, and achieves the effect of reducing labor intensity and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Work process of the present invention is: see Figure 7

[0029] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

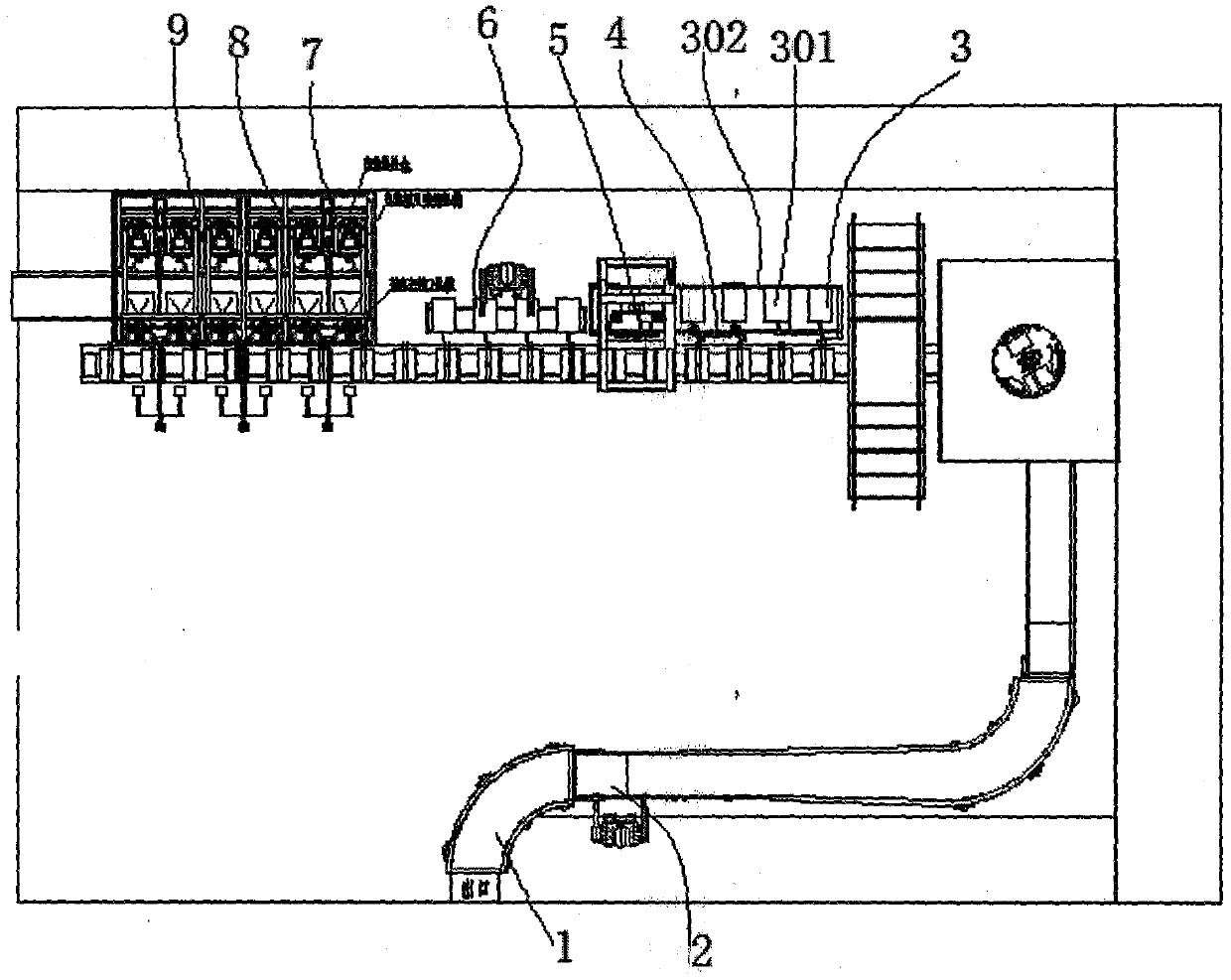

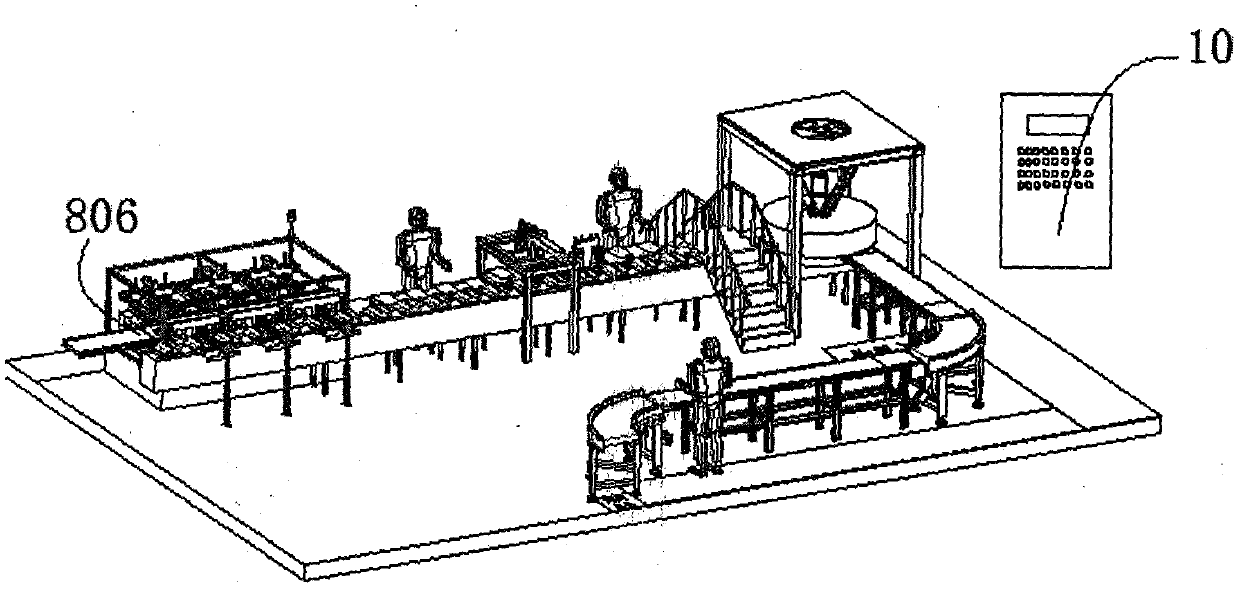

[0030] Such as Figure 1-7 As shown, an abdominal dialysate internal packaging line equipment includes a conveying line body 1, a light inspection station 2, a waste liquid bag feeding device 3, a tube cutting and inflating device 4, an automatic intubation device 5, and a finishing line according to the process sequence. Line body 6, packaging bag feeding device 7, automatic bagging device 8, automatic vacuum sealing device 9 and power distribution control box 10;

[0031] The waste liquid bag feeding device 3 is composed of a positioning tooling plate 301 and a feeding plate chain conveyor 302;

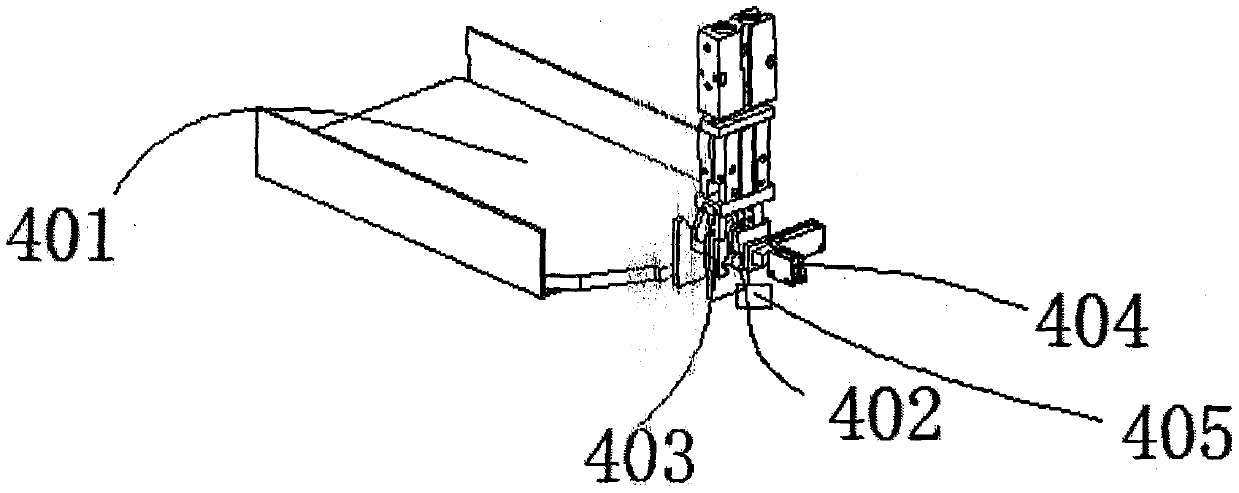

[0032] The pipe cutting and inflating device 4 is composed of a pipe cutting and inflating positioning tooling plate 401, a cutter 402, a clamping and positioning device 403, a reciprocating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com