A treatment method and system for high-concentration refractory pharmaceutical wastewater

A technology for pharmaceutical wastewater and treatment methods, which is applied in the fields of natural water treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of high reliability requirements of automatic control systems, high equipment idle rate, and increased operating costs, etc. To achieve the effect of stable residual pollutants, reduced labor intensity, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

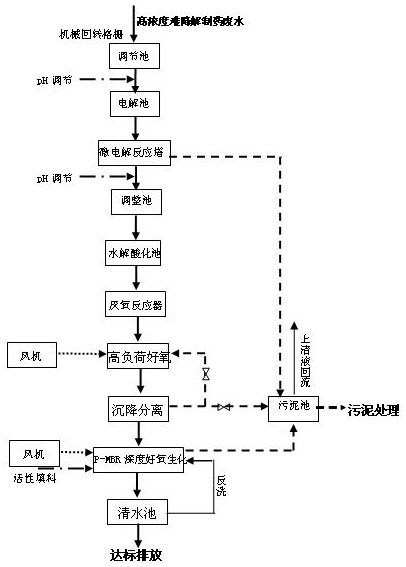

[0038] combine figure 1 , the present embodiment provides a method for treating high-concentration refractory pharmaceutical wastewater, comprising the following steps:

[0039] Step 1) The high-concentration refractory pharmaceutical wastewater enters the adjustment tank for mixing adjustment of water volume and water quality: the residence time in the adjustment tank is 12-24 hours, adjust the pH between 4-7, and enter the electrolytic tank after adjustment;

[0040] The high-concentration pharmaceutical wastewater passes through the mechanical rotary grille to intercept the suspended solids and large floating solids in the wastewater to prevent the pipes and pumps from being blocked, and then enters the regulating pool. The residence time of the regulating pool is set to 12 to 24 hours. Mixing regulation to reduce the impact of water quality on the system. A submersible mixer is installed in the pool for mixing to prevent sedimentation and corrosion. An aeration mixing sys...

Embodiment 2

[0072] This embodiment provides a method for treating high-concentration refractory pharmaceutical wastewater, comprising the following steps:

[0073] Step 1) The high-concentration refractory pharmaceutical wastewater enters the adjustment tank for mixing adjustment of water volume and water quality: the residence time in the adjustment tank is 12 hours, the pH is 4, and after adjustment, it enters the electrolytic tank;

[0074] The high-concentration pharmaceutical wastewater is intercepted by the mechanical rotary grille to intercept the suspended solids and large floating solids in the wastewater to prevent the clogging of pipes and pumps, and then enters the regulating pool, and fully mixes and adjusts the volume and quality of the wastewater to reduce the impact of the water quality on the system. A submersible mixer is installed in the pool for mixing to prevent sedimentation and corrosion. An aeration mixing system is not used to prevent the toxic gas in the wastewate...

Embodiment 3

[0088] This embodiment provides a method for treating high-concentration refractory pharmaceutical wastewater, comprising the following steps:

[0089] Step 1) The high-concentration refractory pharmaceutical wastewater enters the adjustment tank for mixing adjustment of water volume and water quality: the residence time in the adjustment tank is 24 hours, the pH is 7, and after adjustment, it enters the electrolytic tank;

[0090] Step 2) Perform electrolysis in the electrolytic cell: in the electrolytic cell, a Ti-based PbO 2 plated electrode is used as the anode, and a stainless steel electrode is used as the cathode to electrodeposit heavy metals in the wastewater. The electrolysis time is 4 hours, the voltage is 4V, and the current is 6A. The COD of this embodiment The removal rate can reach 45%, remove cyanide, and heavy metals copper, lead and zinc, enter the micro-electrolysis reaction tower after electrolysis;

[0091] Step 3) Carry out micro-electrolysis reaction in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com