Automatically-operated garbage disposal system

A waste treatment system and automatic operation technology, applied in the direction of biomass post-treatment, biomass pre-treatment, biochemical instruments, etc., can solve the problems of low utilization efficiency, easy to be affected by weather, secondary pollution, etc., and achieve high utilization efficiency , not easily affected by the weather, strong insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

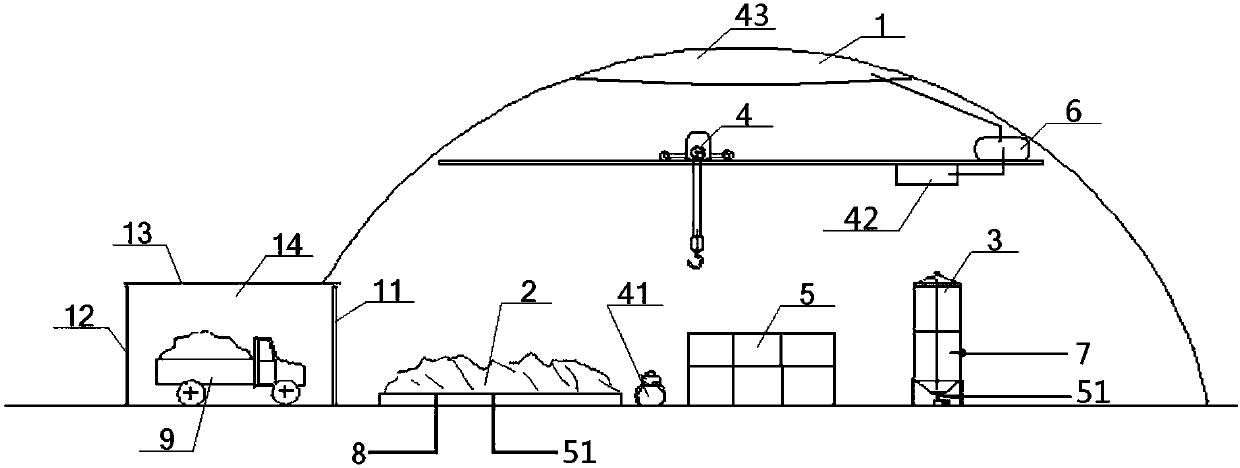

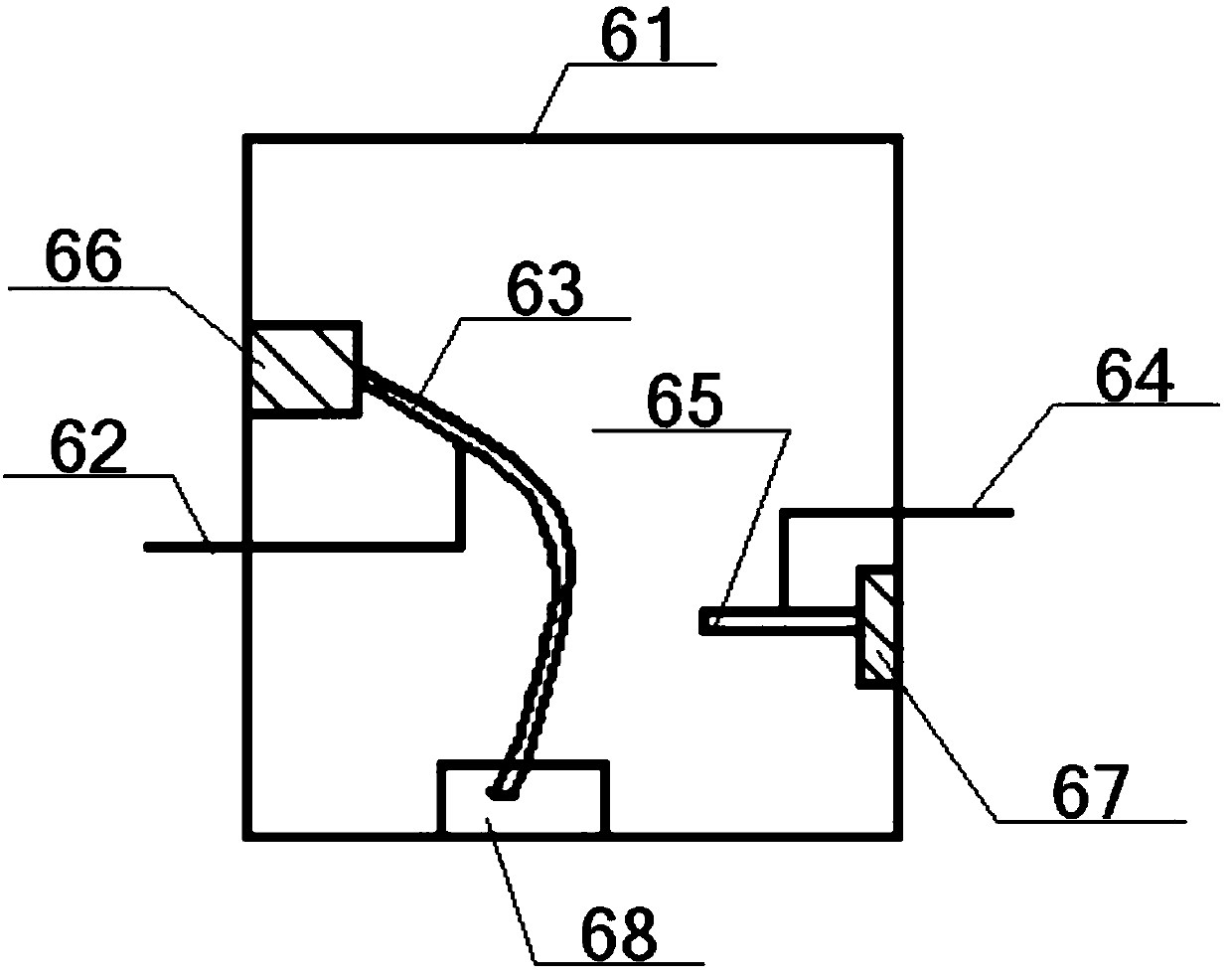

[0033] see figure 1 and figure 2, an automatic operation type garbage disposal system, comprising an air curtain room 1 and a sorter 2 arranged inside it, a gasification furnace 3, a remote control crane 4, a grab bucket 41, and a central control room 5; the air curtain room 1 It is an arched structure, and the left side of the air curtain room 1 is provided with an inner airtight door 11 (it may also include an outer airtight door 12 and an outer air curtain roof 13, an outer airtight door 12, an outer air curtain roof 13, an inner airtight door The door 11 and the ground together form an airtight transition room 14. A special garbage truck 9) is arranged in the airtight transition room 14. The bottom of the air curtain room 1 is located between the inner airtight door 11 and the right side of the air curtain room 1. Sorting machine 2, grab bucket 41, central control room 5, and gasifier 3 are arranged in sequence in the middle part, and remote-controlled crane 4 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com