Cathode protection test probe, cathode protection test device and method for evaluating cathode protection effect of metal in seawater

A cathodic protection and testing device technology, applied in the field of devices and evaluation of cathodic protection effect of metals in seawater, cathodic protection test probes, can solve the problem that cracks are easily formed on the sealing edge of insulating coatings, crevice corrosion cannot be evaluated at the same time, and insulating coatings are easy to remove There are problems such as residues, so as to achieve the effects of low manufacturing cost, strong practicability, and improved stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

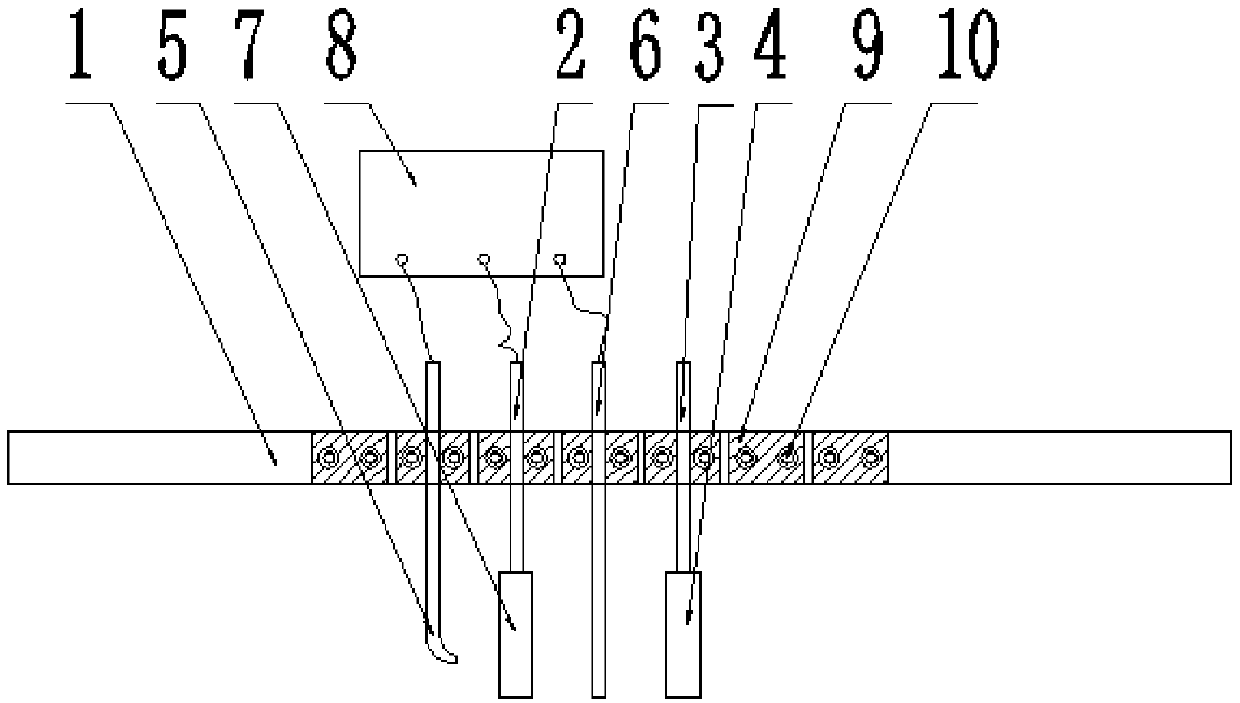

[0096] like figure 1 - Figure 5As shown, the present embodiment provides a cathodic protection test probe, including an insulating support rod 1, a sample connecting rod, a working electrode 7, a comparative sample 4, a reference electrode 5 and an auxiliary electrode 6; the sample connecting rod includes a first The sample connecting rod 2 and the second sample connecting rod 3, one end of the first sample connecting rod 2 is threadedly connected to the working electrode 7, the other end is connected to the electrochemical workstation 8 through a wire, and one end of the second sample connecting rod 3 It is threadedly connected with the comparative sample 4, and the other end is a free end; the working electrode 7, the comparative sample 4, the reference electrode 5 and the auxiliary electrode 6 are all fixed on the insulating support rod 1; the working electrode 7, the reference electrode 5 and the auxiliary electrode The electrodes 6 are all connected to an electrochemica...

Embodiment 2

[0102] like Image 6 As shown, the present embodiment provides a cathodic protection testing device, including the cathodic protection test probe described above, and also includes a test container 21, a water storage tank 22 and a circulation pump 23; the cathodic protection test probe is arranged in the test container 21, stored The water tank 22 is connected to the test container 21 through a pipeline, and both the water storage tank 22 and the test container 21 are connected to a circulating pump 23 .

[0103] The test container 21 is connected with a constant temperature control device 24 .

Embodiment 3

[0105] In this embodiment, the method for evaluating the cathodic protection effect of metals in seawater provided by the present invention is used to evaluate the general corrosion resistance of 9Ni steel when the cathodic protection potential is -0.80V. The test medium is natural seawater from Qingdao, the seawater is kept flowing, the temperature is 20°C, the reference electrode is a saturated calomel electrode, and the test time is 7 days.

[0106] Figure 7 (a) and Figure 7 (b) shows the corrosion morphology of the comparison sample and the cathodic protection sample (ie, the working electrode) after the test, respectively. like Figure 7 (a) and Figure 7 As shown in (b), the surface of the comparison sample is severely corroded, covered with reddish-brown corrosion products, and the corrosion rate is 0.2355mm / a; while the surface of the sample under the cathodic protection potential of -0.80V is smooth and metallic, and the corrosion rate is 0.0056 mm / a, the degree...

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com