Stereoscopic light-emitting lamp sheet-based LED light source

A LED light source, three-dimensional technology, applied in the direction of electric solid-state devices, semiconductor devices, electrical components, etc., can solve the problems of insufficient brightness, limited brightness, small size, etc., to improve light efficiency and heat dissipation, compact structure, and overall reduced size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

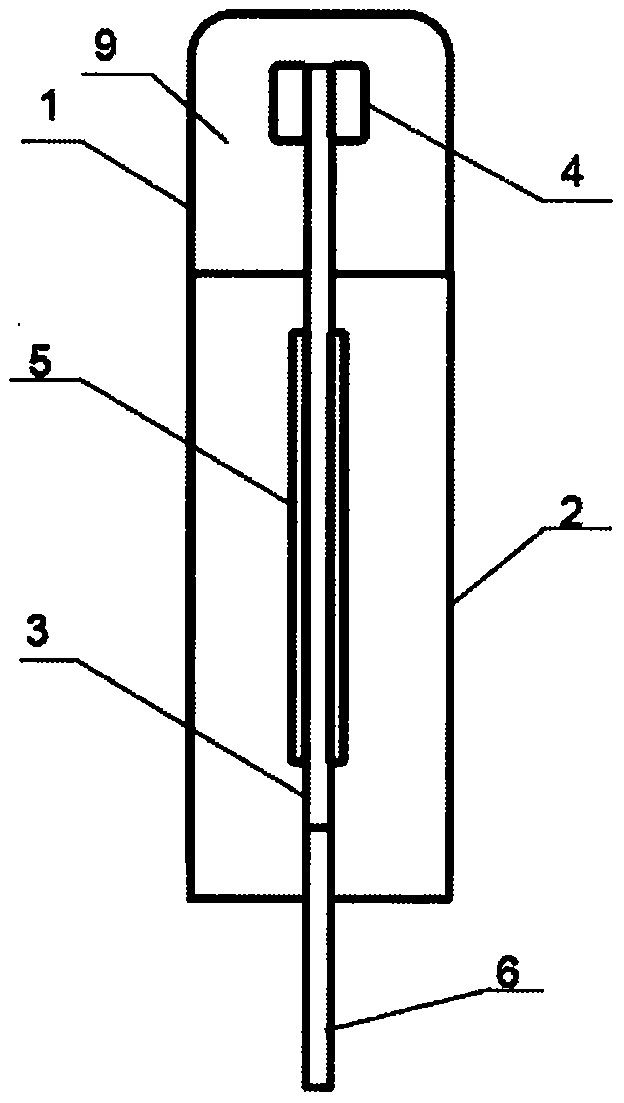

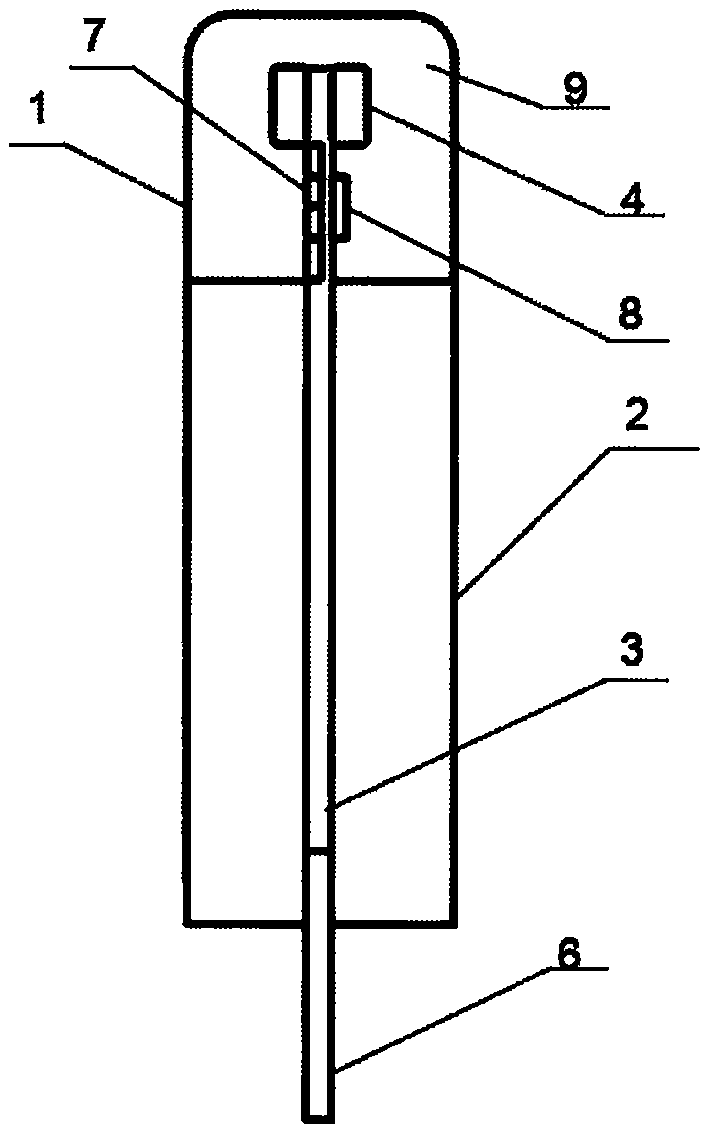

[0018] Depend on figure 1 It can be seen that an LED light source based on a three-dimensional light-emitting lamp sheet includes a transparent silica gel 1, a heat-conducting insulating plastic 2, and a packaging substrate. The transparent silica gel 1 and the heat-conducting insulating plastic 2 are integrally connected up and down.

[0019] In the present invention, the packaging substrate is divided into a light-emitting area, a power supply packaging area, and a stitch welding area; the light-emitting area includes a substrate 3 with a circuit that can emit light on both the front and back sides of the transparent silica gel 1. As a preferred embodiment of the present invention, the substrate The light-emitting area of 3 includes any one of a transparent substrate (glass, ceramic, sapphire) or non-transparent substrate (copper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com