Ultrasonic motor rapid response device

An ultrasonic motor, fast response technology, applied in the direction of generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc., can solve problems that have not yet been popularized, and achieve good anti-interference and reliability performance, low power consumption, and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with drawings and embodiments.

[0019] Such as figure 1 , The ultrasonic motor quick response device is composed of a feeding box, an inclined pipe, a vertical pipe, a receiving box and a three-way pipe, all of which are made of transparent plexiglass. The inner diameter of the inclined pipe and the vertical pipe is 30mm, and the bracket is made of stainless steel. The angle of the inclined tube is adjustable, thereby controlling the falling speed of the black and white balls, so that the signal sensed by the photoelectric sensor is coordinated with the motor action. The ultrasonic motor moves according to the black and white ball signals sensed by the photoelectric sensor and the position of the motor at this time, and drives the dial to detect black and white balls.

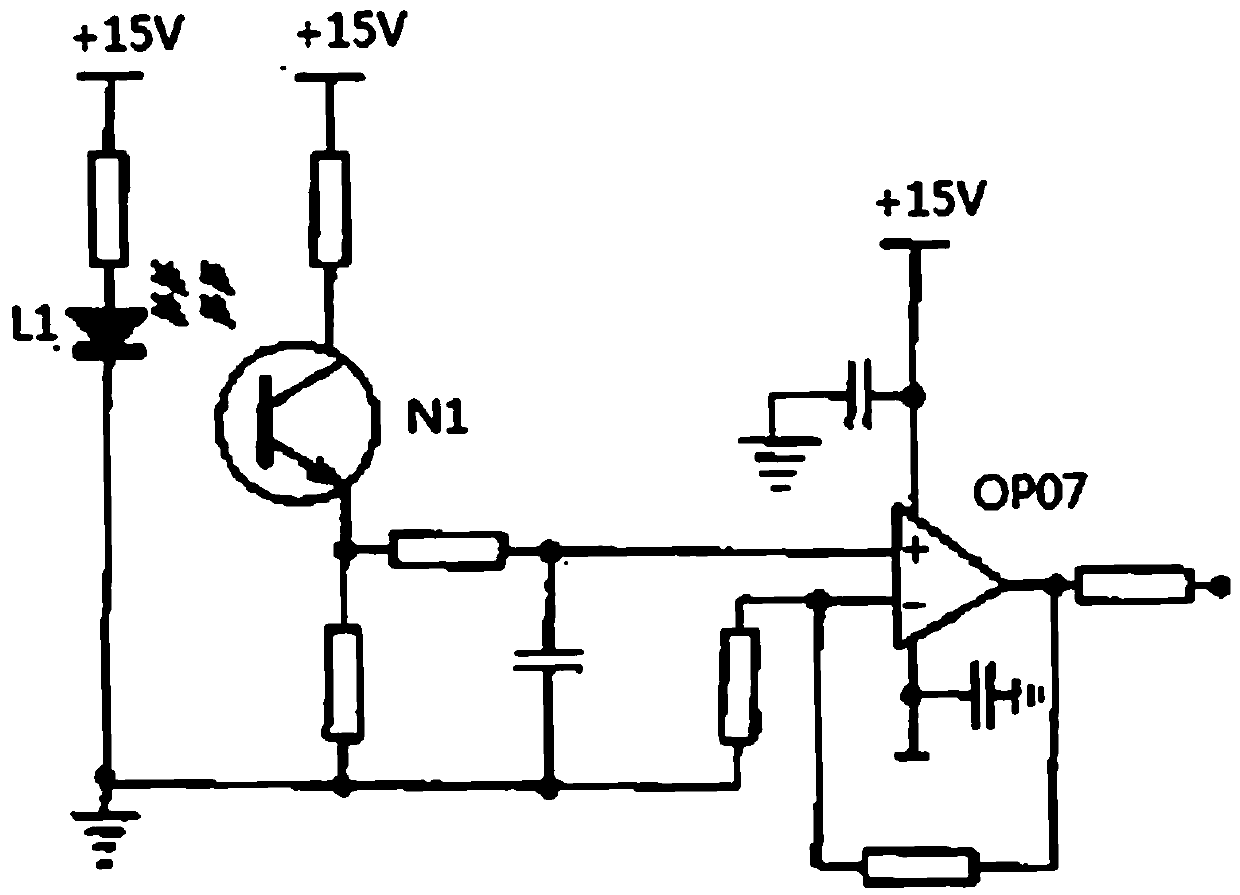

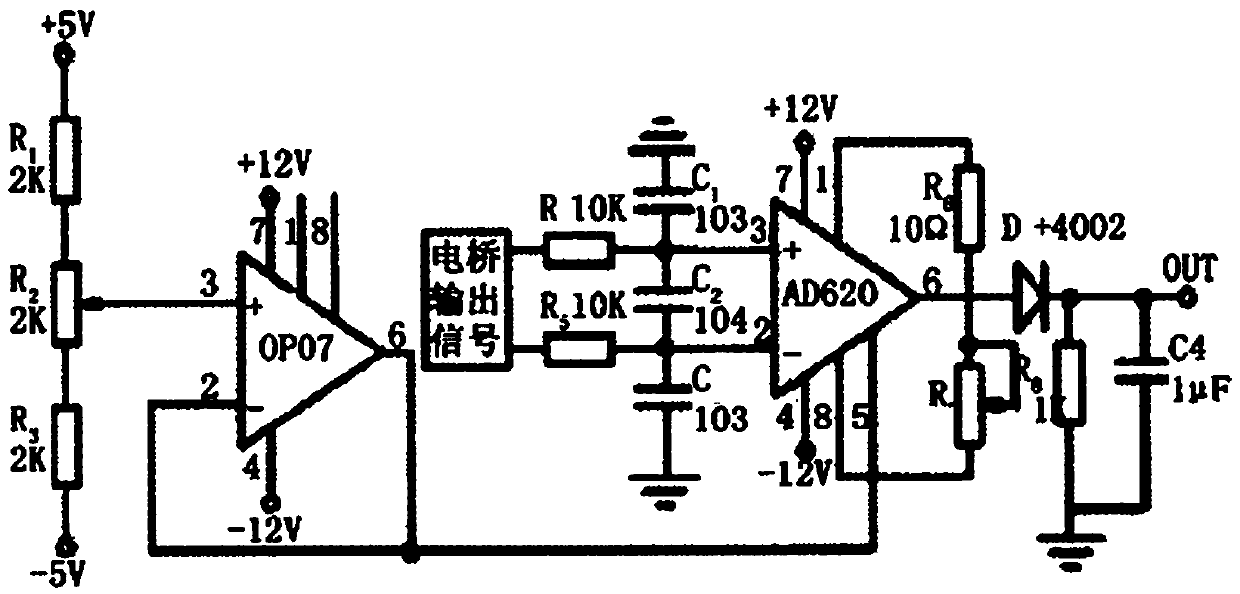

[0020] Such as figure 2 , In the detection drive circuit, the forward and reverse timing of the motor is detected by the photoelec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com