Preparation method of moxa roll

A technology of shaft core and tissue paper, applied in the field of moxa rolls, can solve the problems of insufficient hardness, soft collapse at both ends of moxa rolls, and unfavorable separation of warm moxibustion sticks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Weigh 50 grams of rosin and dissolve in 500 milliliters of absolute ethanol, stir to dissolve, let stand for 24 hours to obtain solidified solution 1;

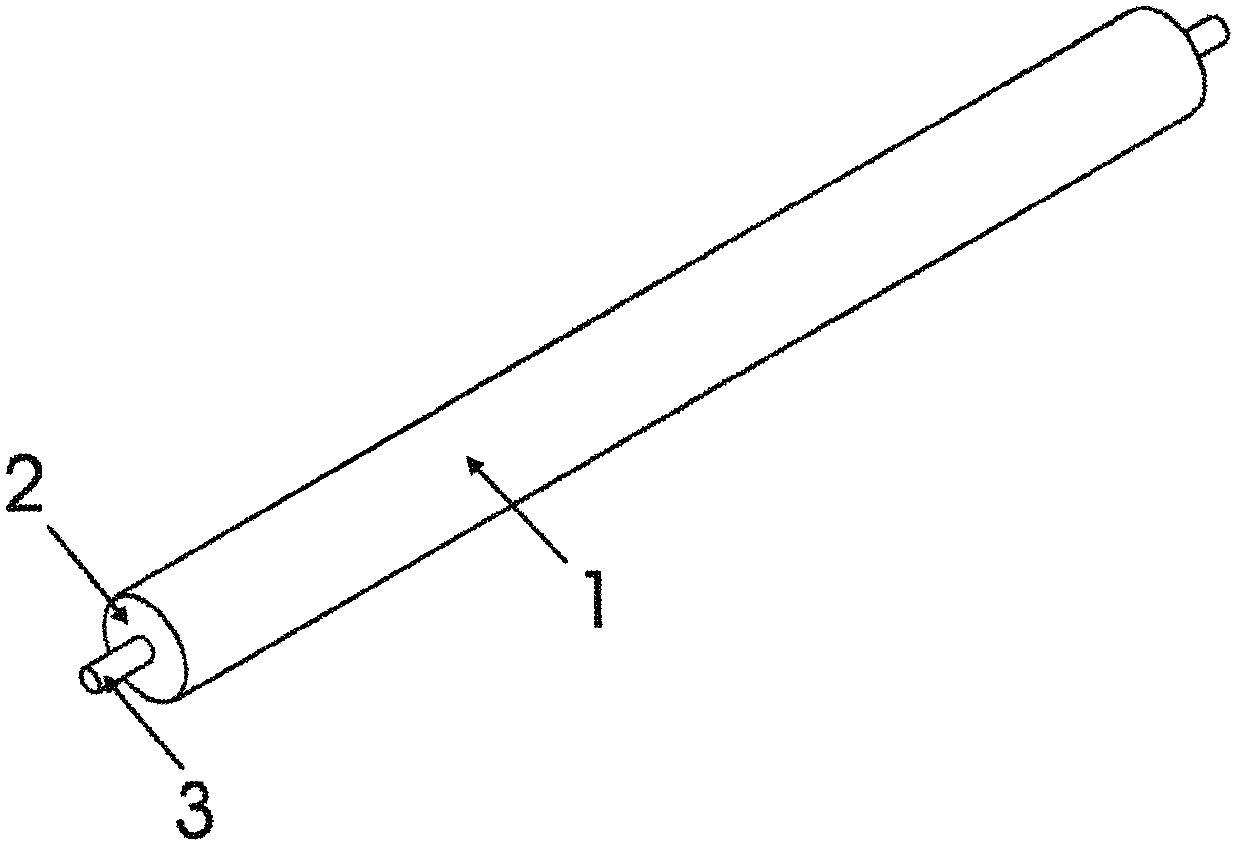

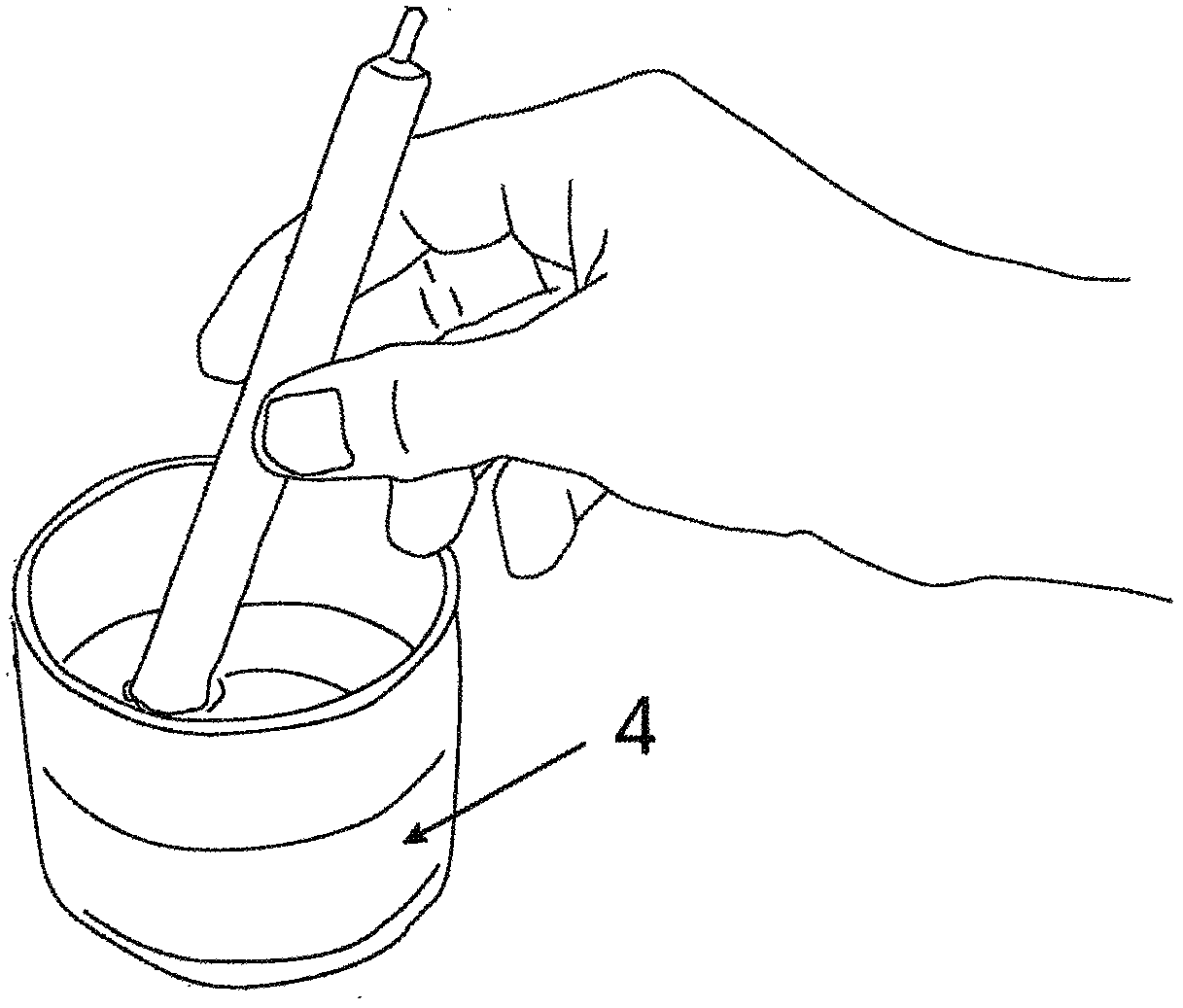

[0033] Weigh 1 gram of refined moxa, spread it evenly on 100mm x 100mm tissue paper, use a stainless steel wire with a diameter of 1.2mm as the core of the extraction axis, roll it up manually, rub it tightly in the same direction with a self-made pressing plate, and lift the tissue paper, Apply the paste, then wrap it tightly, pull out the shaft core after drying, clean the excess moxa at both ends, apply or soak the solidifying solution 1 on the whole strip, let it dry naturally, and then put it into a sealed packaging bag for later use.

Embodiment 2

[0035] Weigh 1 gram of frankincense and soak it in 100 milliliters of absolute ethanol, heat, stir, let stand for 24 hours, take the liquid, and obtain solidified liquid 2;

[0036] Weigh 1 gram of refined moxa, spread it evenly on 100mm x 100mm tissue paper, use a stainless steel wire with a diameter of 1.2mm as the core of the extraction axis, roll it up manually, rub it tightly in the same direction with a self-made pressing plate, and lift the tissue paper, Apply the paste, then wrap it tightly, pull out the shaft core after drying, clean up the excess moxa at both ends, apply or soak the solidifying solution 2 on the whole strip, let it dry naturally, and put it into a sealed packaging bag for later use.

Embodiment 3

[0038] Weigh 100 grams of myrrh and soak in 100 milliliters of absolute ethanol, heat, stir, stand still for 24 hours, take the liquid to obtain solidified liquid 3;

[0039] Weigh 5 grams of refined moxa, spread it evenly on 100 mm x 200 mm tissue paper, use a stainless steel wire with a diameter of 2.0 mm as the core of the extraction shaft, roll it up by hand, rub and compact it in the same direction with a self-made pressing plate, and lift the tissue paper , apply the paste, rub it tightly again, pull out the shaft core after drying, clean up the excess moxa at both ends, and immerse it in the curing solution 3 to a depth of about 2 mm, take it out, dry it naturally, and put it in a sealed bag for later use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com