Hollow-fiber composite biological membrane

A fiber composite and biofilm technology, applied in the field of biofilm, can solve the problems of black and smelly water, difficulty in balancing oxidant resistance and membrane flux, and membrane fouling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

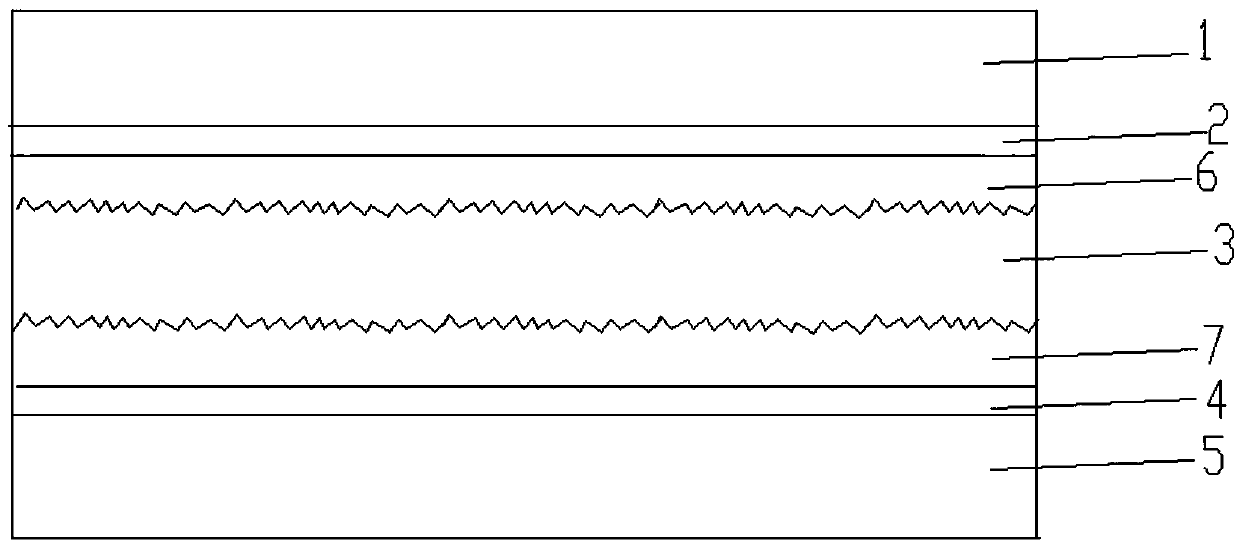

[0016] Embodiment: A kind of hollow fiber composite biofilm, this hollow fiber composite biofilm is tubular, comprises hollow fiber membrane outer layer 1, graphene oxide outer layer 2, biofilm layer 3, graphene oxide inner layer sequentially from outside to inside 4 and hollow fiber membrane inner layer 5, the section of described biofilm layer is zigzag, is provided with plasticizer outer layer 6 between described graphene oxide outer layer and biofilm layer, described biofilm layer and graphite oxide A plasticizer inner layer 7 is arranged between the vinyl inner layers.

[0017] Both the plasticizer outer layer and the plasticizer inner layer are dioctyl phthalate layers.

[0018] The thickness of the outer layer of the hollow fiber membrane and the inner layer of the hollow fiber membrane are both 1-2mm.

[0019] The thicknesses of the graphene oxide outer layer and the graphene oxide inner layer are both 500-700nm.

[0020] The thickness of the biofilm layer is 1-2mm. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com