Centering pin positioning guide structure

A technology of positioning guide and centering needle, which is applied in binding and other directions, can solve the problems of increasing the overall cost of the binding machine, affecting the riveting quality, affecting the appearance of documents, etc., and achieves the effect of simple structure, good riveting quality and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to enable those skilled in the art to better understand the technical solution of the present invention, the product of the present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings.

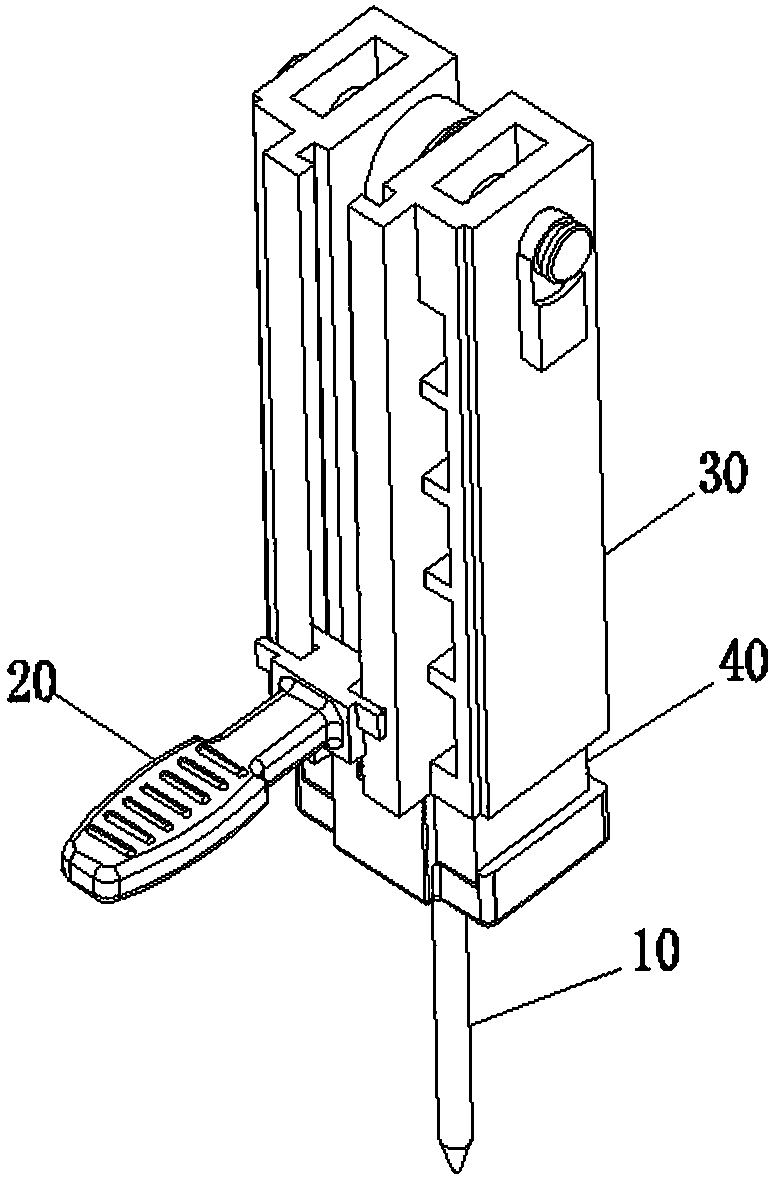

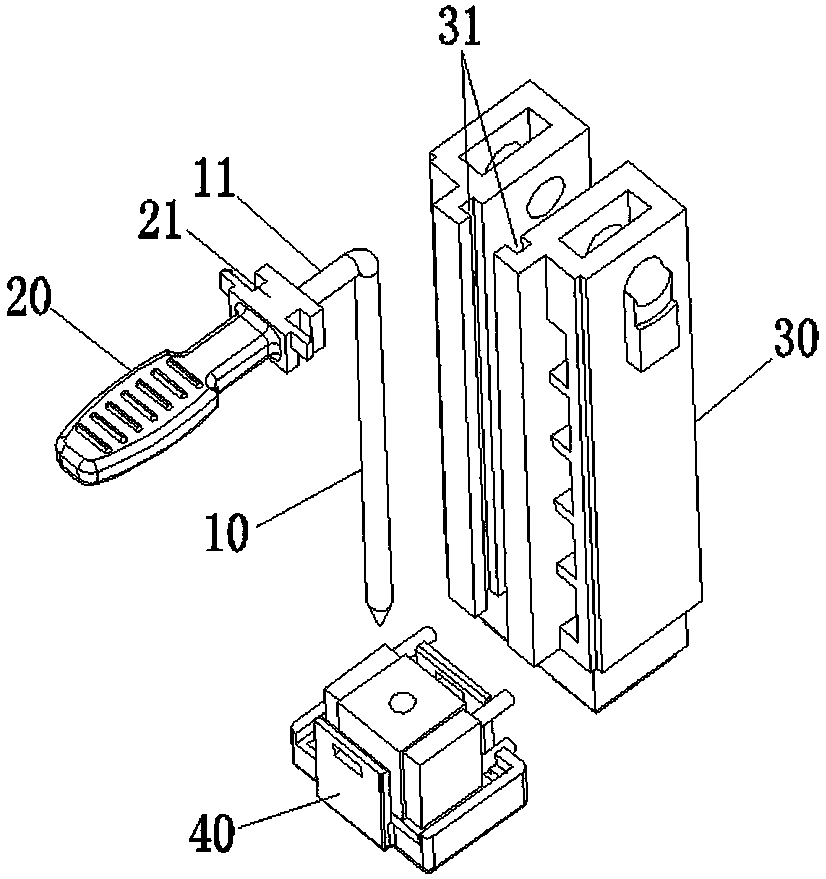

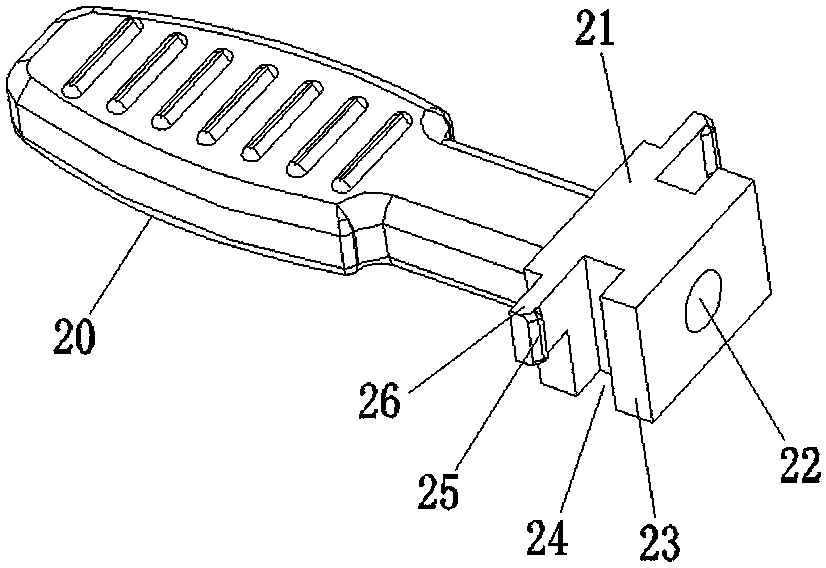

[0020] Such as figure 1 and figure 2 As shown, a centering pin 10 positioning guide structure includes a centering pin 10 located above the rivet head assembly 40, the centering pin 10 is located in the middle of the drive block 30 above the rivet head assembly 40, and the centering pin 10 The upper end of the upper end is provided with a horizontal bending portion 11 bent forward, and the outer end of the horizontal bending portion 11 is provided with a handle 20 made of elastic plastic, and one end of the handle 20 connected to the horizontal bending portion 11 A sliding positioning part 21 is provided, and the two sides of the front end of the driving block 30 are provided with slide grooves 31 oppositely distri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com