Plate split mounting type road surface manufactured by utilizing waste plastics

A waste plastic, assembled technology, applied in the direction of paving, roads, roads, etc. paved with prefabricated blocks, can solve the problems of shortening construction time, environmental pollution, etc., and achieve easy maintenance and disassembly of pipelines, good wear resistance, and high temperature resistance. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

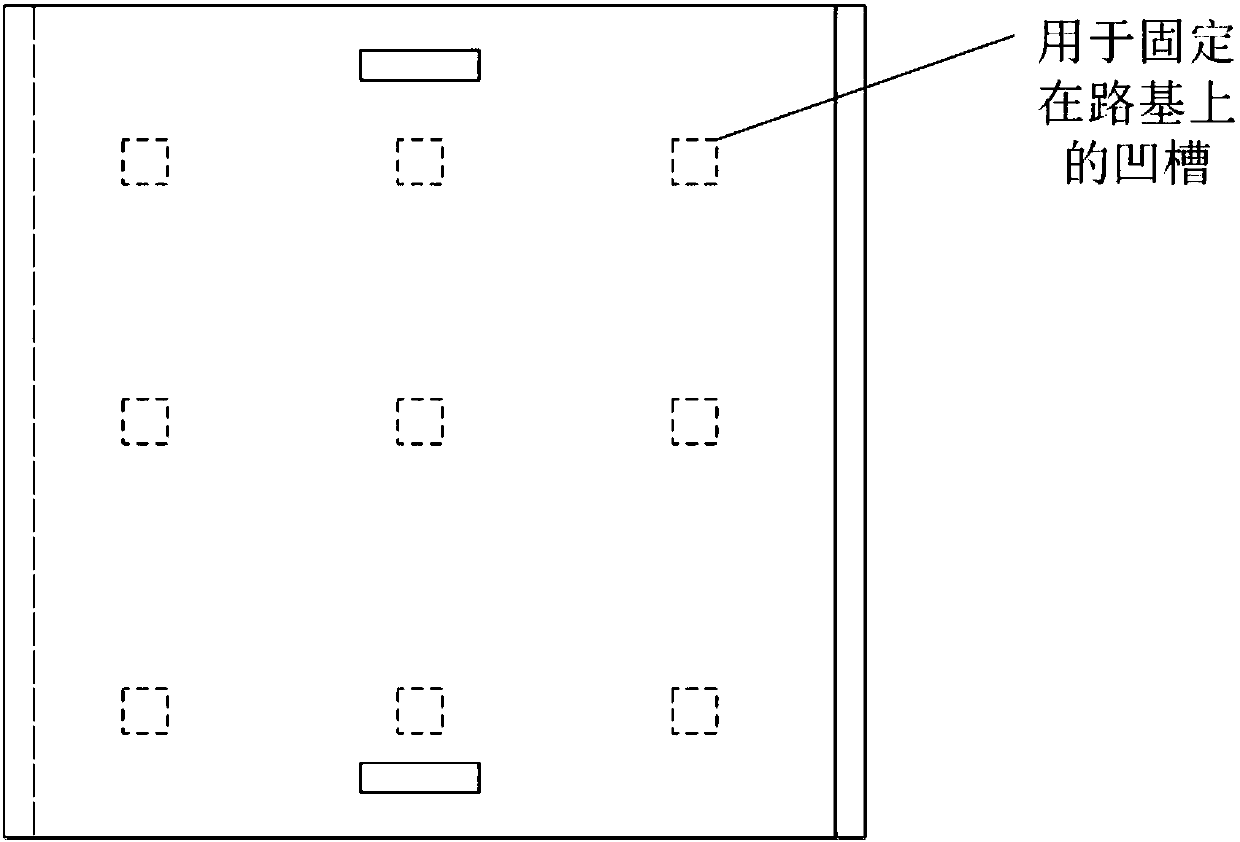

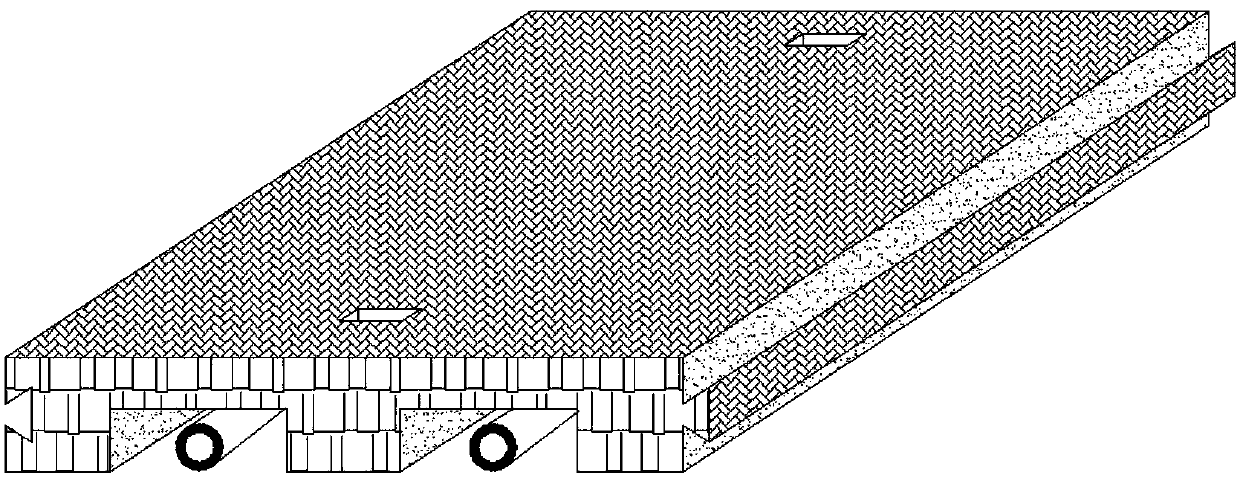

[0044] Such as image 3 As shown, a panel-assembled pavement made of waste plastics includes a plurality of waste plastics to make assembly blocks, and a space is reserved at the bottom of each assembly block for the construction pipeline 6 to pass through.

[0045] Further, the shape of the assembly block can be designed according to actual engineering needs, for example, it can be designed as a square, a rectangle, a circle, a ring and so on.

[0046] Furthermore, the left and right sides of the assembly block are provided with protrusions and grooves for connecting with adjacent assembly blocks, so that two adjacent pavement panels can be socketed together.

[0047] There are many shapes of protrusions and grooves, which can be designed as Figure 5 , 6 , Various shapes shown in 7; the matching surface of the protrusion and the groove can be designed as an irregular concave-convex surface.

[0048] Further, the upper and lower sides are provided with drilled holes for stee...

Embodiment 2

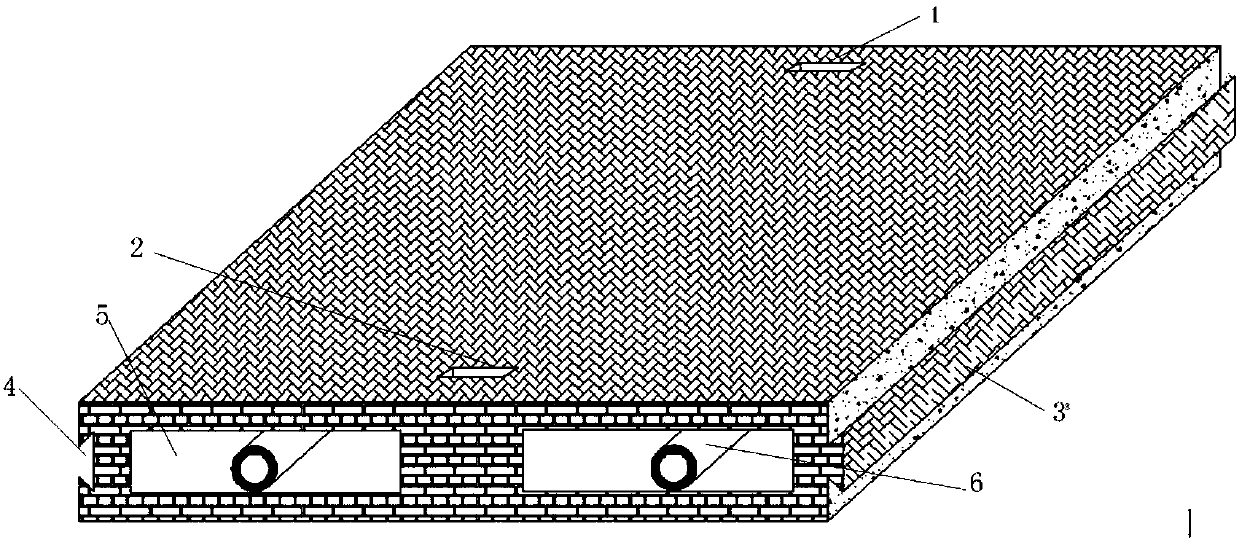

[0052] Such as figure 2 As shown, the present invention proposes a panel-assembled pavement made of waste plastics, including a plurality of waste plastics to make assembly blocks, each assembly block is a hollow structure, and the hollow structure is for the construction pipeline 6 to pass through Space.

[0053] Further, the shape of the assembly block can be designed according to actual engineering needs, such as square, rectangular, circular, circular and so on.

[0054] Furthermore, the left and right sides of the assembly block are provided with protrusions 3 and grooves 4 for connecting with adjacent assembly blocks, so that two adjacent pavement panels can be inserted together.

[0055] There are many shapes of protrusions and grooves, which can be designed as Figure 5 , 6 , Various shapes shown in 7; in order to increase the connection force between adjacent permeable road substrate blocks, the matching surfaces of the protrusions and grooves can be designed as i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com