Hot flushing method of boiler system and boiler system

A hot state flushing and boiler technology, applied in the direction of boiler cleaning equipment, etc., can solve the problems of high energy consumption, auxiliary equipment, power consumption, and fuel consumption, and achieve the effects of reducing energy consumption, reducing a large amount of water consumption, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

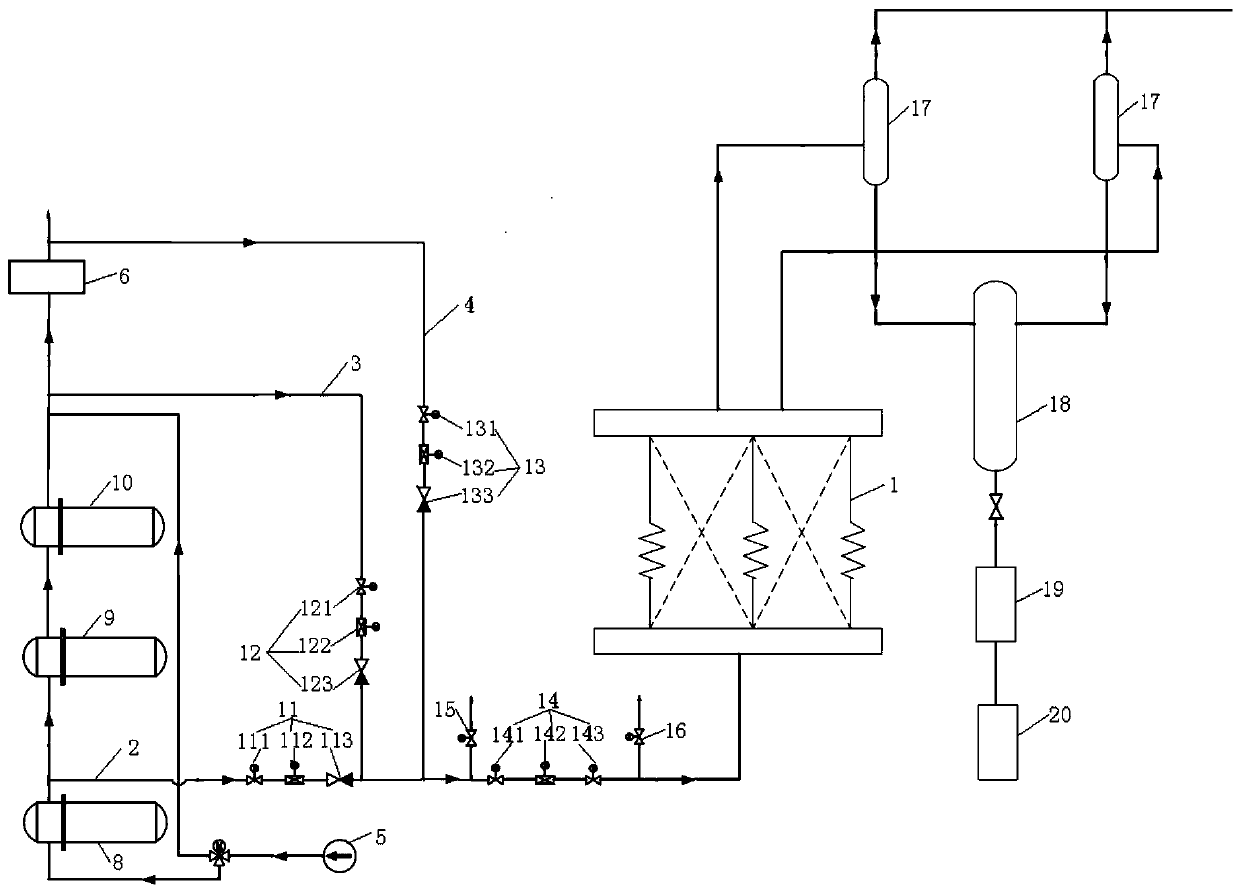

[0024] Such as figure 1 As shown, this embodiment provides a boiler system, including a boiler, the boiler includes a boiler water wall 1, and the boiler system also includes a bypass pipe and an inlet valve group arranged on the bypass pipe for controlling water inlet. The inlet of the bypass pipe is connected to the adjacent boiler, and the outlet of the bypass pipe is connected to the boiler water wall 1. The bypass pipe is used to introduce the water vapor obtained by heating the adjacent boiler into the boiler water wall 1 of the boiler to be started for hot flushing . The water vapor used in hot flushing is obtained by heating desalinated water, which is ordinary water to remove salts contained in water, such as sodium salts, calcium salts, etc., to obtain relatively pure water.

[0025] In order to ensure the safety of generator set operation, general power plants are configured with two or more generator sets, and each generator set includes at least one boiler. When...

Embodiment 2

[0049] This embodiment provides a hot flushing method using the boiler system in Embodiment 1, in which steam heated by an adjacent boiler is introduced into the boiler water wall of the boiler to be started for hot flushing.

[0050] In this embodiment, the temperature of the steam for hot flushing is 200° C., the pressure of the steam for hot flushing is 26 MPa, and the amount of water added to the steam for hot flushing is 300 tons / hour.

Embodiment 3

[0052] This embodiment provides a hot flushing method using the boiler system in Embodiment 1, in which steam heated by an adjacent boiler is introduced into the boiler water wall of the boiler to be started for hot flushing. In this embodiment, the temperature of the steam for hot flushing is 210° C., the pressure of the steam for hot flushing is 20 MPa, and the amount of water added to the steam for hot flushing is 200 tons / hour.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com