Rotary drum rotary-type drying granulating device

A technology of drum rotation and drying, which is applied to drying, dryers, heating devices, etc., can solve the problems of wasting materials, particle size does not necessarily meet the demand, and self-weight increase, so as to increase the heat exchange surface area, Improves and preserves heat and prevents mutual adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below with reference to the accompanying drawings and embodiments, and the mode of the present invention includes but not limited to the following embodiments.

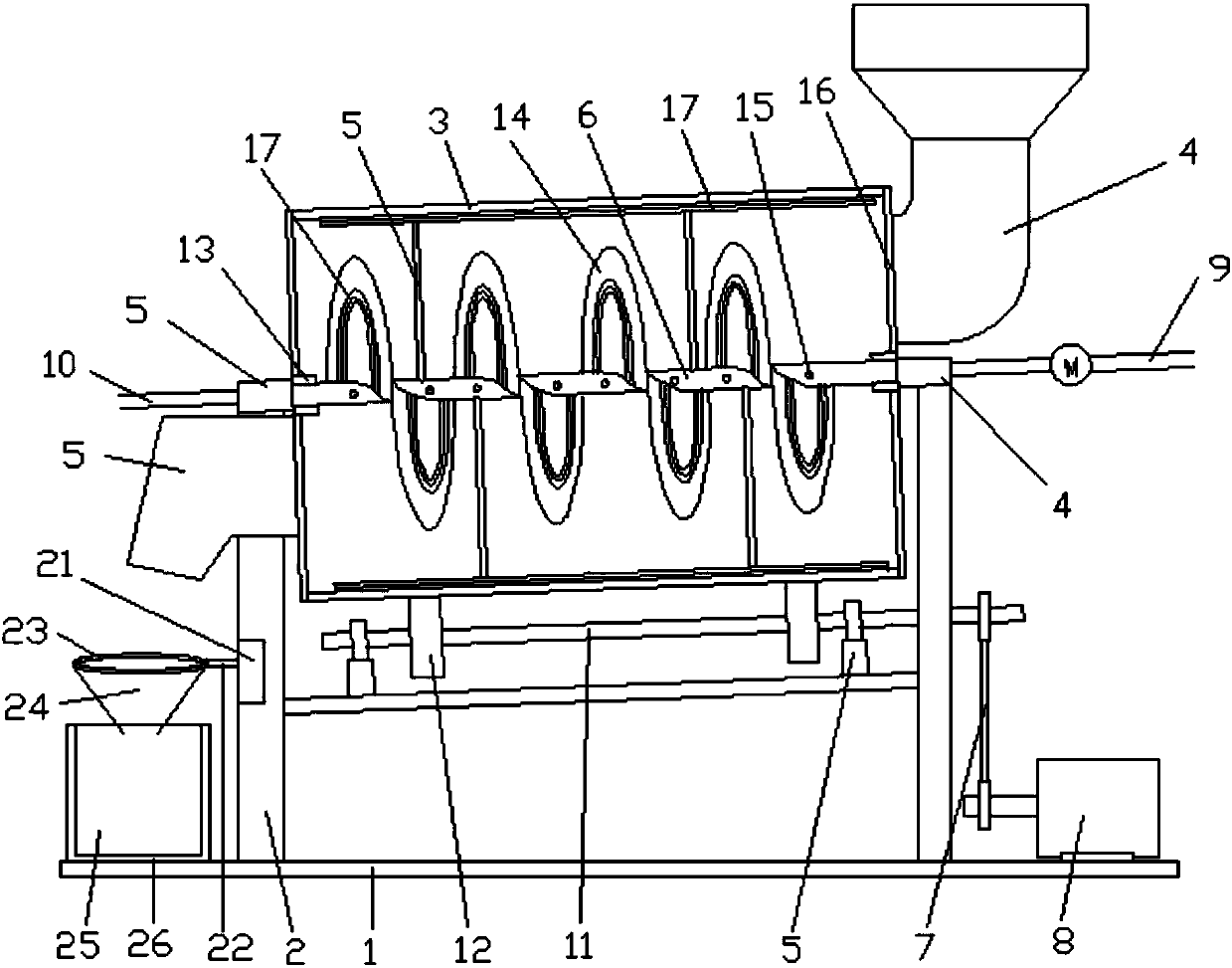

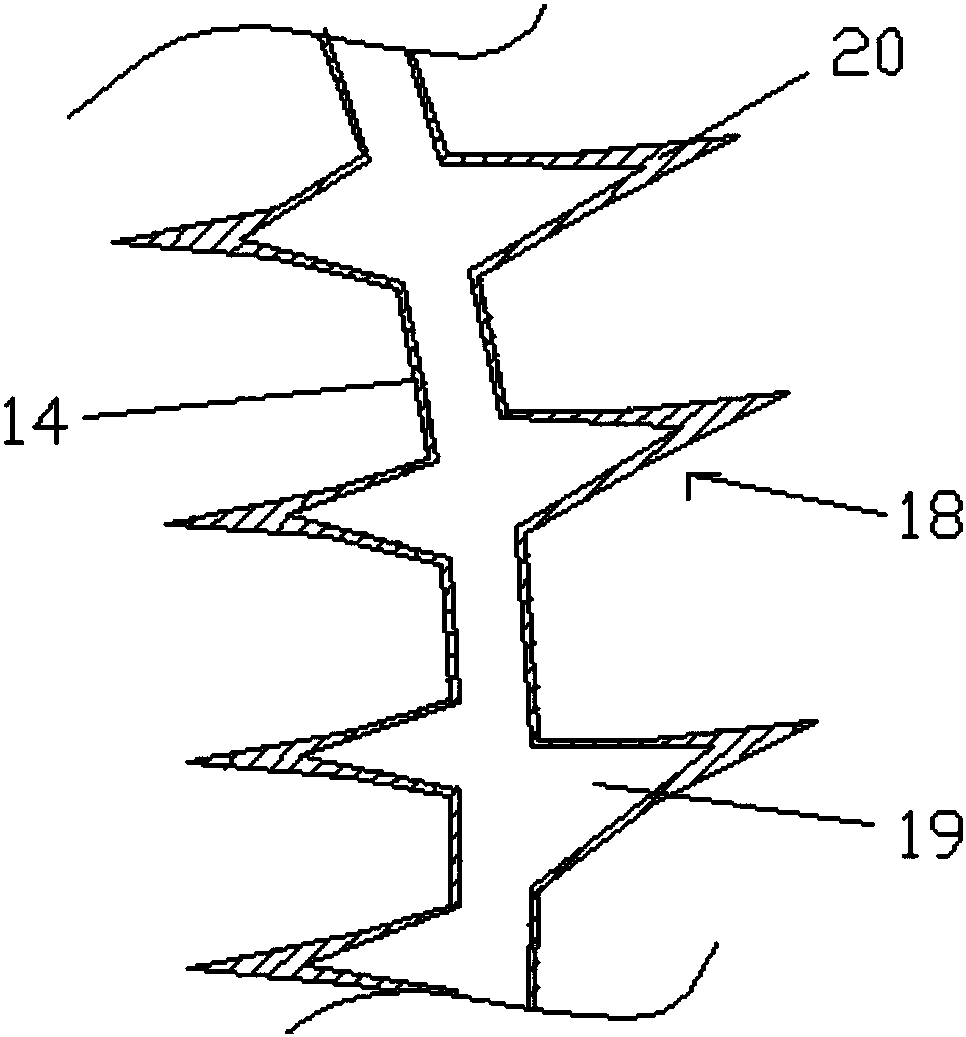

[0022] The purpose of this embodiment is to provide a drum rotating drying granulation device, such as figure 1 with figure 2 As shown, the drying and granulating device includes a base 1, a bracket 2, a rotating drum 3 and a strip scraper 17, and the two ends of the rotating drum are installed on the bracket at an angle of 20° through bearings, and the high end of the rotating drum The side is provided with a feed port 4, and the lower side of the drum is provided with a discharge port 5; the lower ends of the two supports 2 are respectively fixed on the bottom surface through the base 1; the center of the drum 3 is provided with a central axis fixed heat pipe 6. The fixed heat pipe 6 inside the drum is provided with a hollow spiral blade 14 communicating with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com