Periodic gradual change raster display waveguide and manufacturing method and application thereof

A technology of grating display and manufacturing method, applied in the direction of light guide, diffraction grating, optics, etc., can solve the problems of low accuracy and efficiency, limited field of view, burrs, etc., and achieves correction of off-axis large field of view aberration, High precision and diffraction efficiency, the effect of large field of view

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

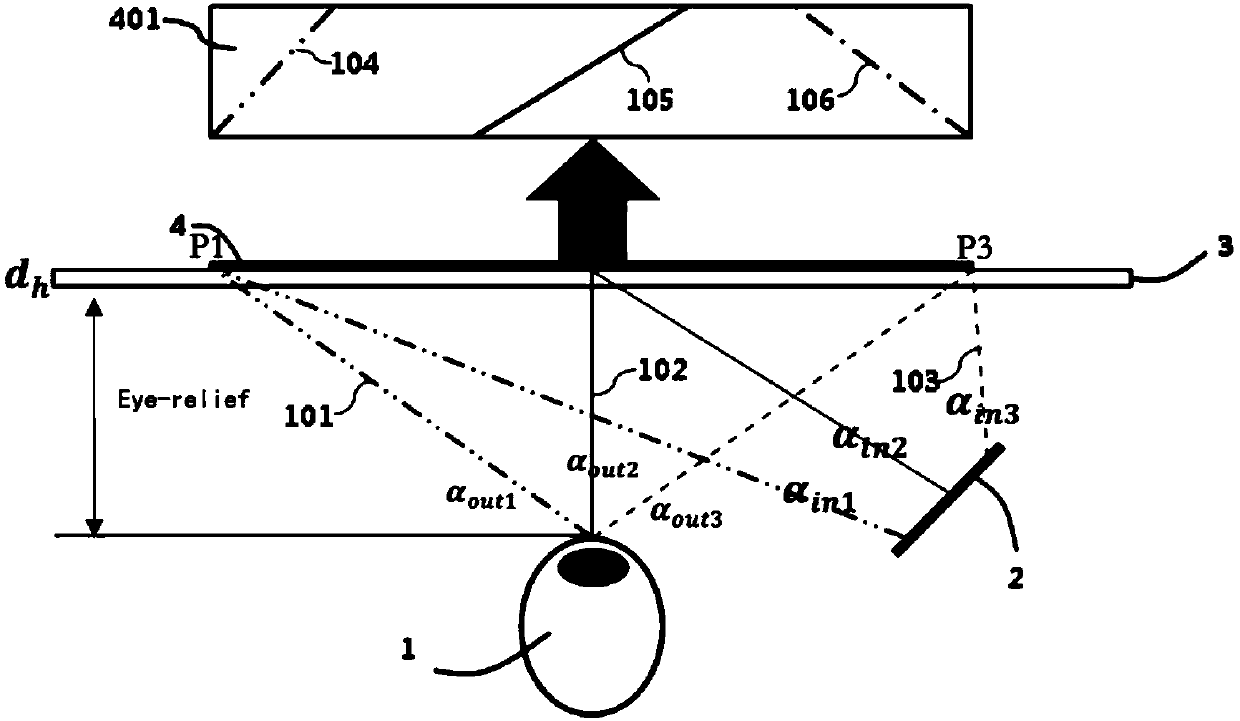

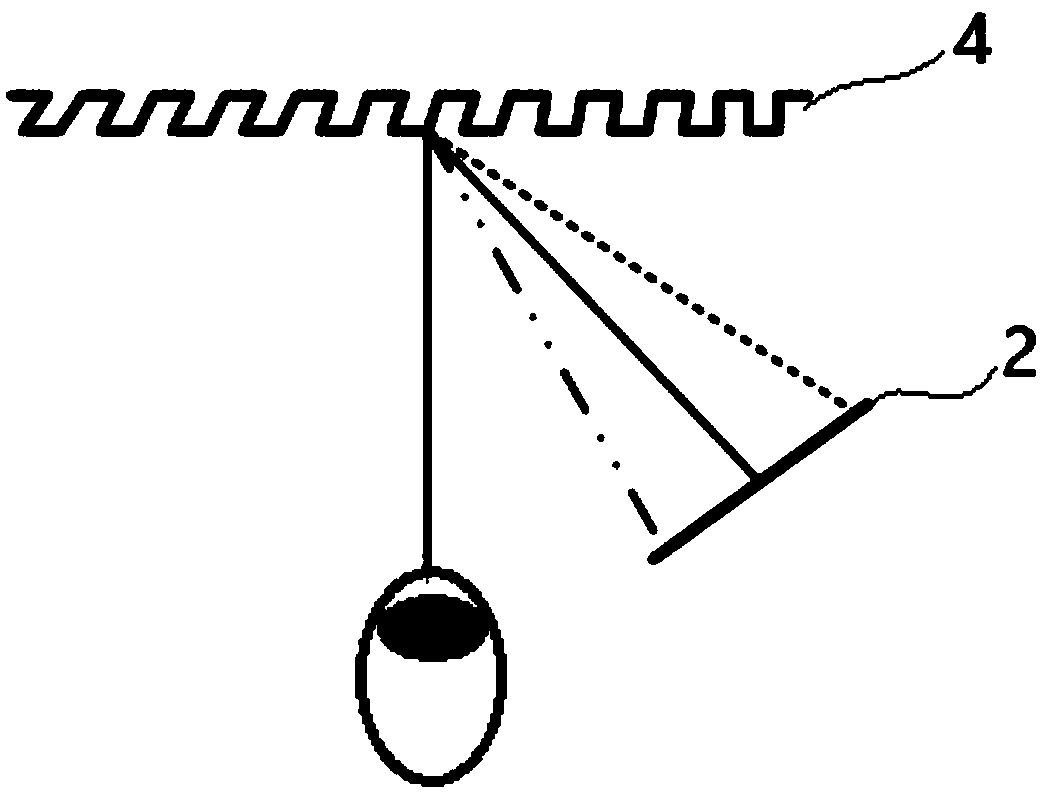

[0043] combine Figure 1-Figure 4 , this embodiment describes in detail the periodic gradient grating display waveguide of the present invention, as figure 1 As shown, it includes: a front surface and a rear surface, a grating structure is arranged on the front surface, and the period and inclination angle of the grating structure are discretely changed at the pixel level along the horizontal direction. The grating structure of this embodiment has an inclined relief grating, the number of inclined relief gratings matches the number of image source pixels, each pixel corresponds to a specific inclined relief grating, and the inclination angle and side length ( That is, the corresponding grating periods) are different. Such as figure 1 As shown, the grating display waveguide in this embodiment is in the shape of a cuboid, the embossed grating surfaces are arranged in the horizontal direction, and the grating period and inclination angle θ gradually change. Such as figure 2 ...

Embodiment 2

[0047] This embodiment describes in detail the manufacturing method of the periodic gradient grating display waveguide of the present invention, which includes the following steps:

[0048]S11: According to the required Eye-relief, combined with the parameters n and d of the base material h Calculate each α in the field of view of the human eye out The exit position P of the light on the grating waveguide;

[0049] P i =f(Eye-lelief,n,d h , α outi ) i=1, 2, 3...;

[0050] S12: The image source on the microdisplay corresponds to the display waveguide on the pixel, such as Figure 4 As shown, the incident ray angle α of a certain pixel point A on the microdisplay in , Corresponding to the exit ray angle α of point P on the waveguide out , the inclination angle θ of the grating at position P can be calculated from the geometric relationship;

[0051]

[0052] S13: According to the incident light angle α of each field of view in , Angle of outgoing light α out , the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com