Substrate processing apparatus and substrate processing method

A substrate processing apparatus and technology for a substrate processing method are applied in the directions of cleaning methods and utensils, chemical instruments and methods, cleaning methods using liquids, etc., which can solve the problems of increased number of substrate processing steps and insufficient cleaning power, and achieve electrical attraction. The effect of strong force and shortening of the total processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084] Hereinafter, embodiments according to the present invention will be specifically described with reference to the drawings.

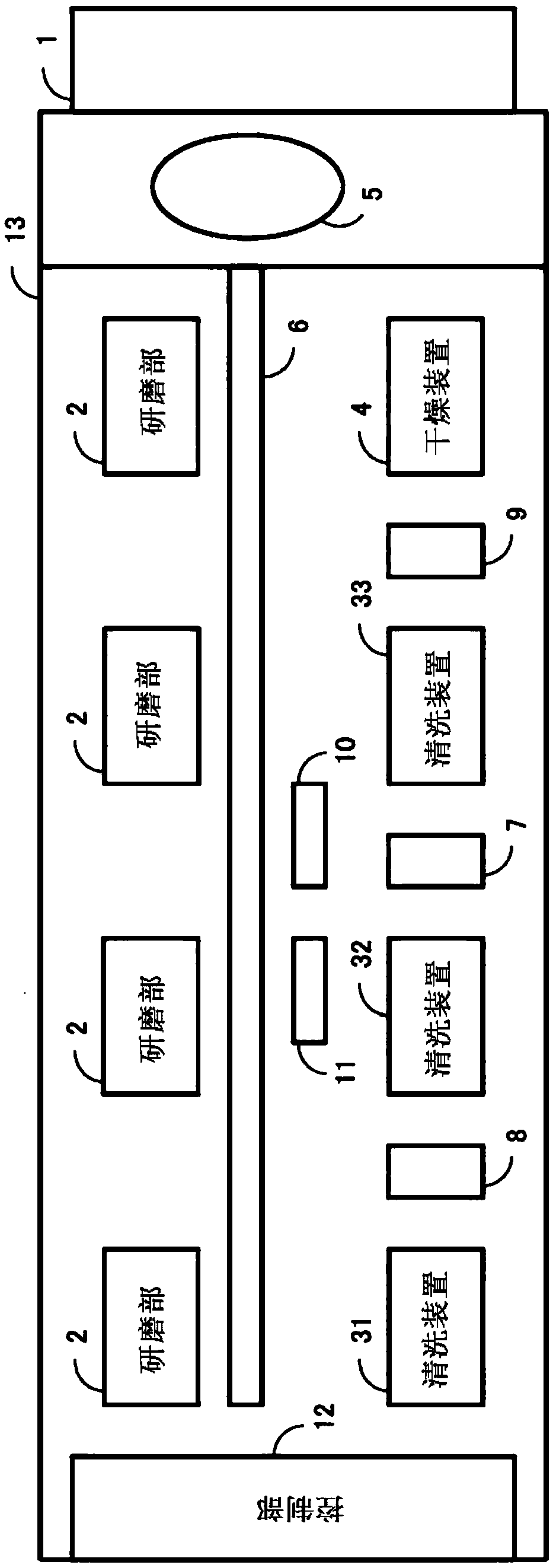

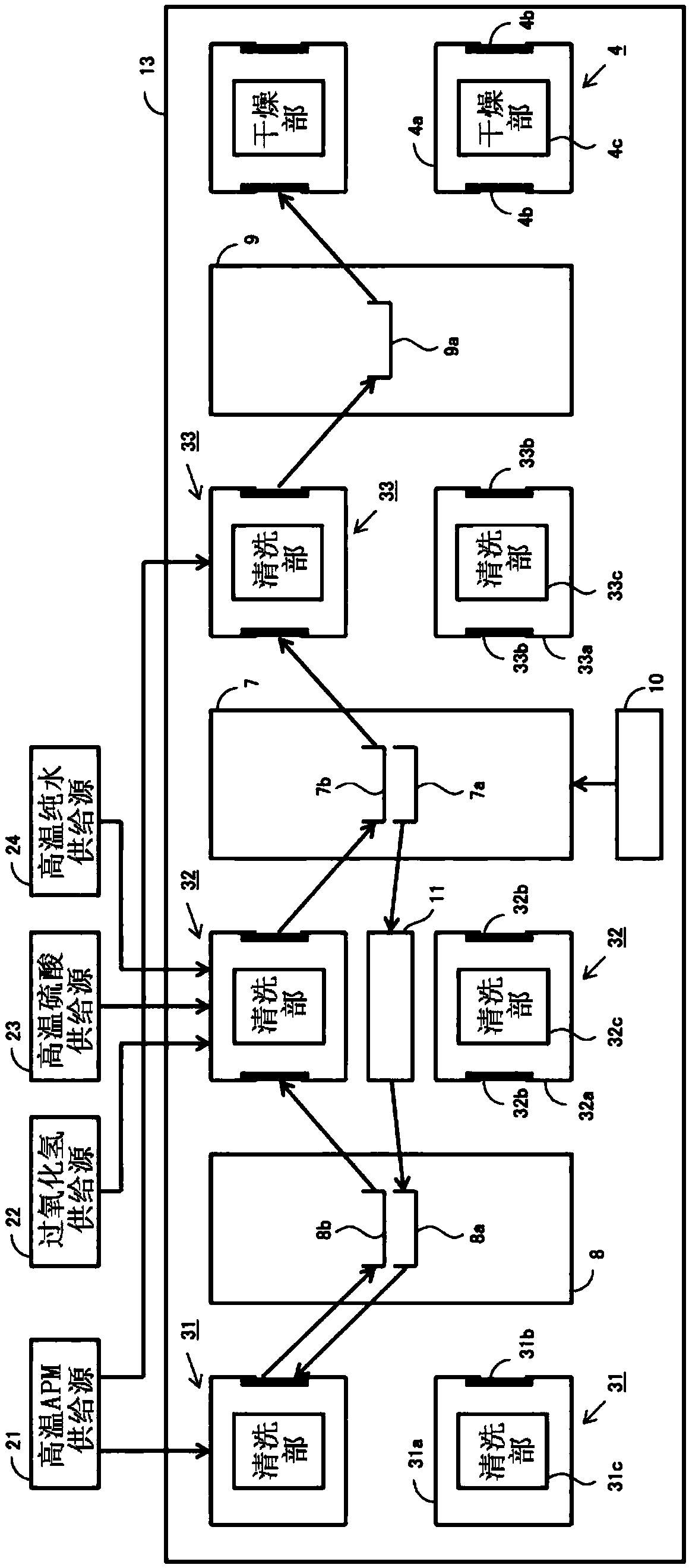

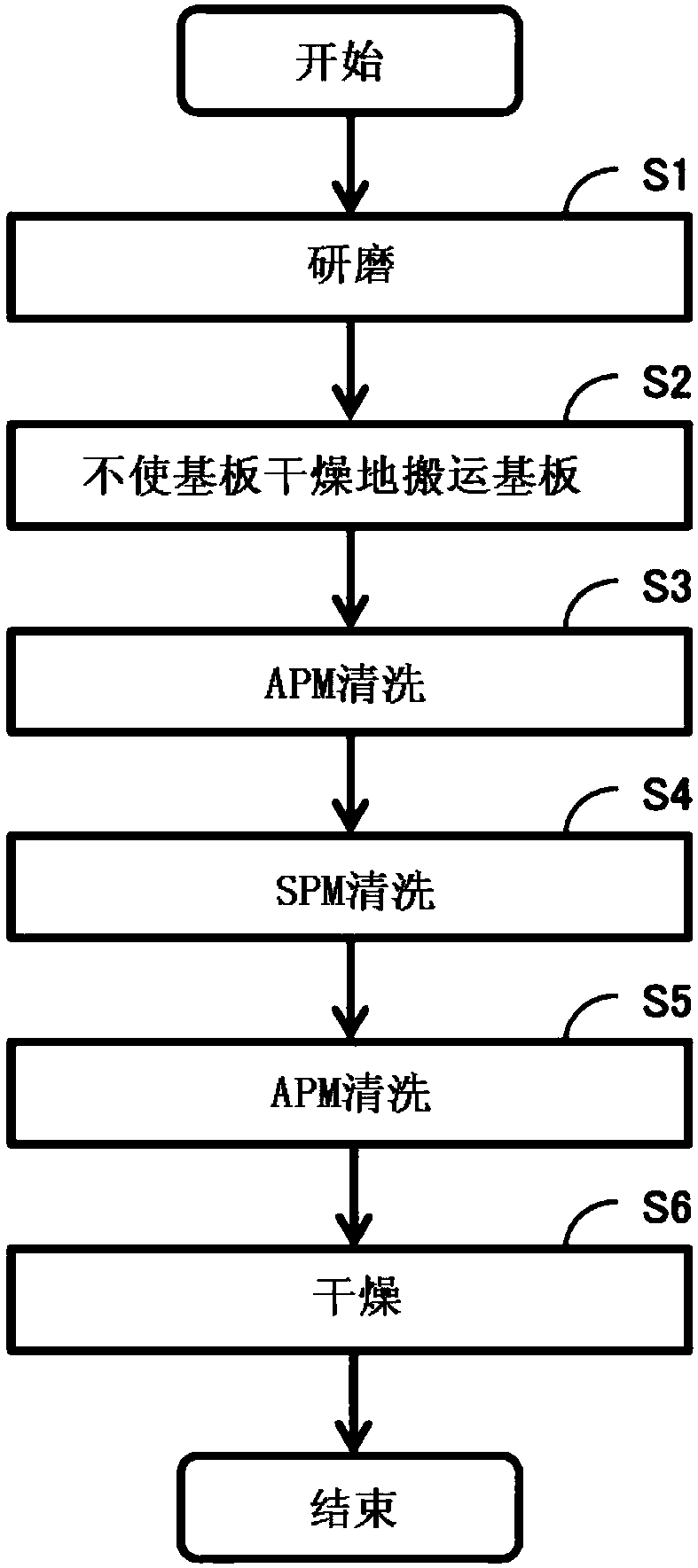

[0085] figure 1 It is an example which schematically shows the outline structure of a substrate processing apparatus, and can also be considered as a schematic plan view of a substrate processing apparatus. The substrate processing apparatus includes: a load port 1 ; one or more polishing units 2 ; a plurality of cleaning devices 31 to 33 ; one or more drying devices 4 ; transfer units 5 to 9 ; substrate stations 10 and 11 ; Each part other than the load port 1 can be accommodated in the device 13 .

[0086] The load port 1 is arranged adjacent to the short side of the device 13, and carries a substrate cassette storing a substrate such as a semiconductor wafer.

[0087] The grinding section 2 is arranged side by side along the long side of the device 13, and uses, for example, a 2 ) slurry to polish the substrate. Slurry remains on the ground...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com