Manufacturing method of contact image sensor

A technology of an image sensor and a manufacturing method, which can be applied to radiation control devices and other directions, and can solve the problems that the structural performance of CIS needs to be improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] It can be seen from the background art that the performance of the CIS structure in the prior art needs to be improved.

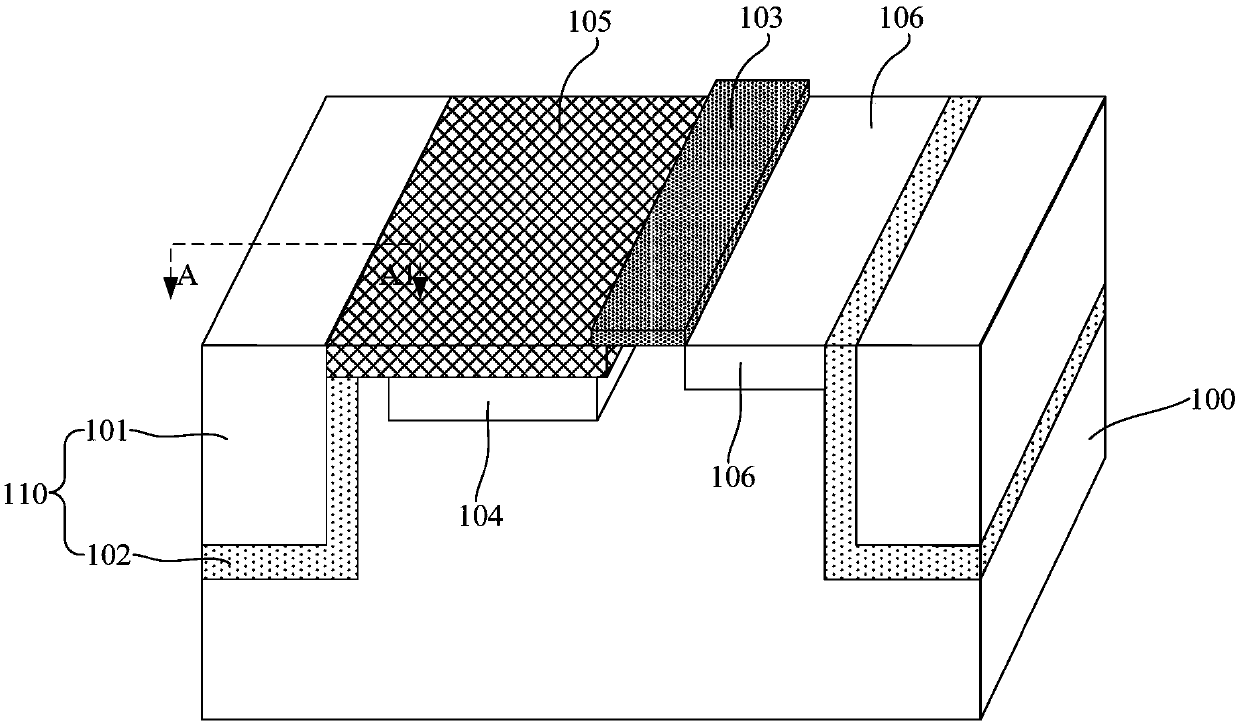

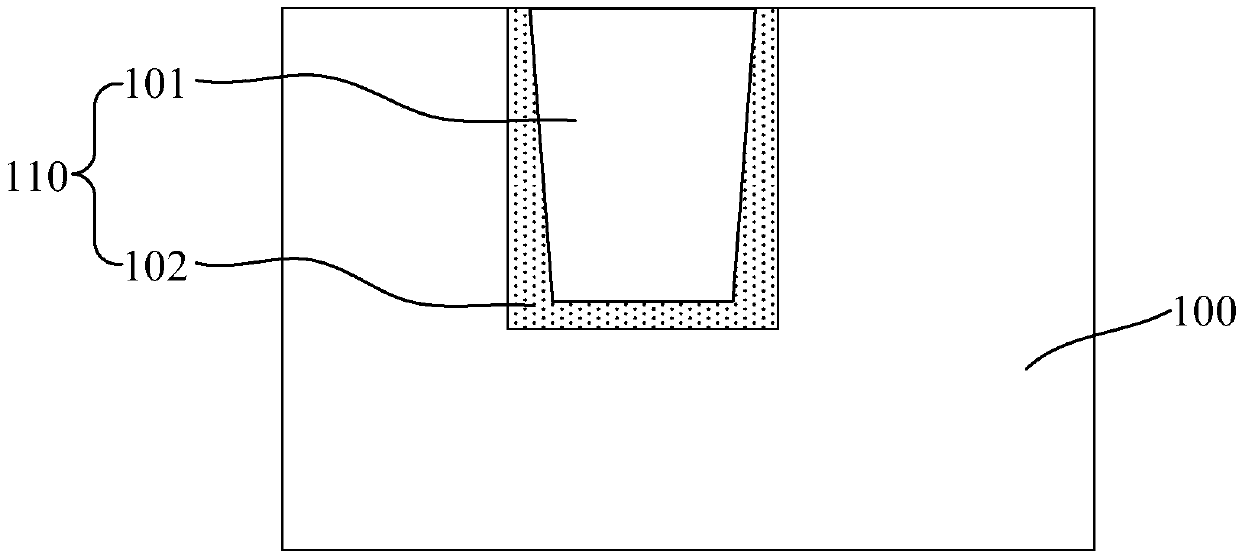

[0027] refer to figure 1 and figure 2 , figure 1 is a schematic diagram of the three-dimensional structure of a single pixel unit in the CIS structure, figure 2 for figure 1 A schematic diagram of a partial cross-sectional structure of the middle substrate and the isolation structure cut along the cutting line AA, the CIS structure includes:

[0028] The substrate 100 has several isolation structures 110 inside, and the area between adjacent isolation structures 110 is an active area, wherein the isolation structure 110 includes: a shallow trench isolation structure 101 and surrounding the shallow trench isolation structure 101. The P+ isolation well 102 of the trench isolation structure 101; the transfer gate 103 located on the partial surface of the active region of the substrate 100; the photodiode in the substrate 100 located on one side of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com