AB5 type hydrogen storage alloy used for nickel-metal hydride battery and preparation method of hydrogen storage alloy

A hydrogen storage alloy and nickel-metal hydride battery technology, applied in the direction of nickel storage battery, battery electrode, alkaline storage battery, etc., can solve the problems of high cost, battery short circuit, etc., and achieve the effect of low cost, low cost and high performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

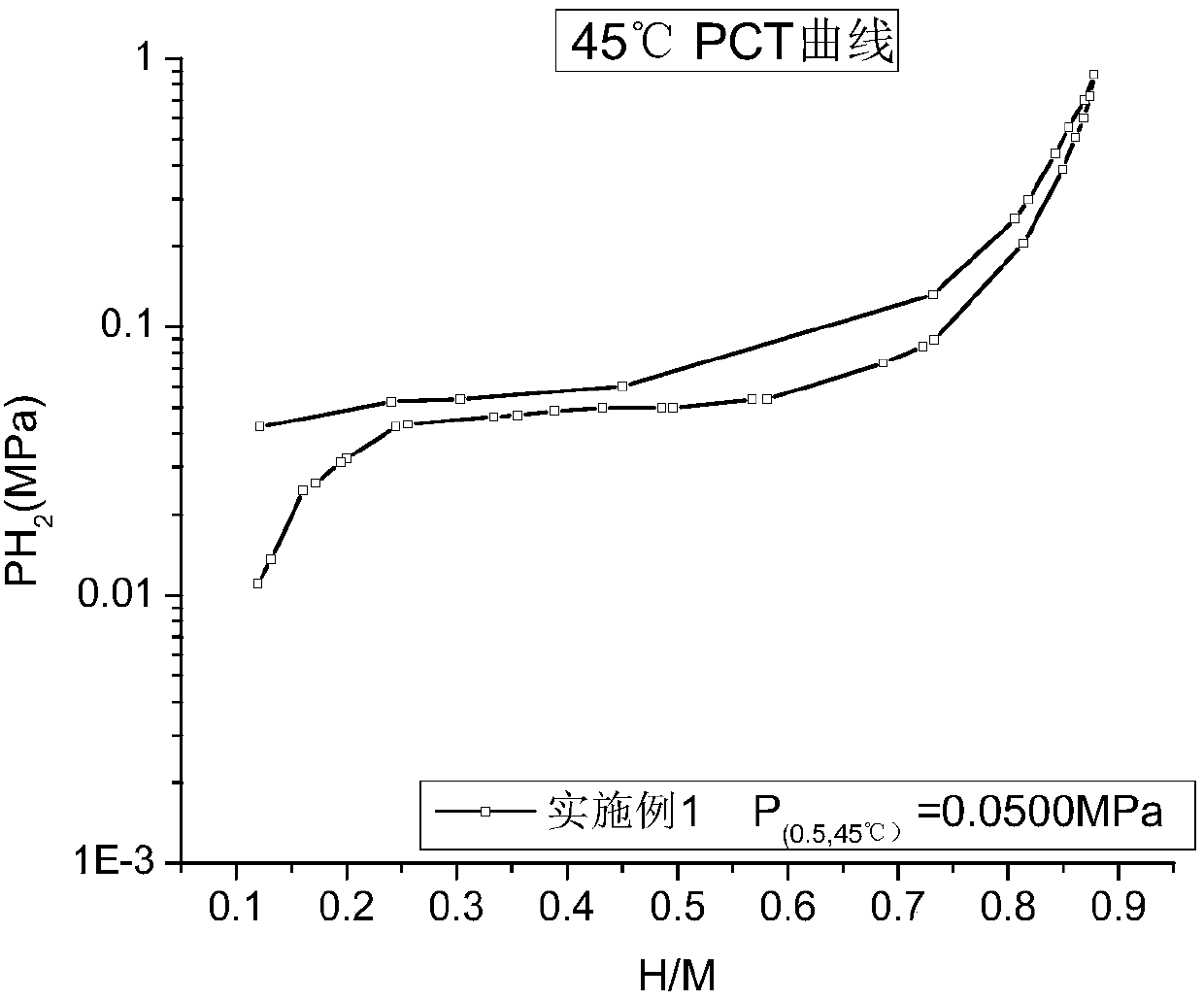

Embodiment 1

[0018] According to the structural formula La 0.793 Ce 0.160 Y 0.040 Zr 0.007 Ni 4.810 mn 0.640 Al 0.240 Weigh the metal raw materials La, Ce, Y, Zr, Ni, Mn, Al, place them in the crucible of the induction melting furnace, vacuumize (1Pa) and fill it with argon gas. The pressure in the furnace is 0.1MPa. Smelting at 1300°C for 2.5 hours to obtain metal smelting liquid; pour the metal smelting liquid into a water-cooled ingot mold and cool to obtain an alloy ingot. Place the alloy ingot in a horizontal heat treatment furnace, vacuumize (1Pa) and fill it with protective gas argon, the pressure in the furnace is 0.1MPa, anneal at 1100°C for 14h, and get AB for nickel-metal hydride batteries after crushing 5 type hydrogen storage alloy.

Embodiment 2

[0020] According to the structural formula La 0.845 Ce 0.150 Zr 0.005 Ni 4.500 mn 0.650 Al 0.400 Weigh the metal raw materials La, Ce, Zr, Ni, Mn, Al, put them in the crucible of the induction melting furnace, vacuumize (5Pa) and fill it with argon gas. The pressure in the furnace is 0.01MPa. Smelting for 1.0 h to obtain a molten metal; pouring the molten metal into a water-cooled ingot mold and cooling to obtain an alloy ingot. Put the alloy ingot in a horizontal heat treatment furnace, vacuumize (5Pa), fill it with protective gas argon, the pressure in the furnace is 0.01MPa, anneal at 1200°C for 5h, and get AB for nickel-metal hydride batteries after crushing. 5 type hydrogen storage alloy.

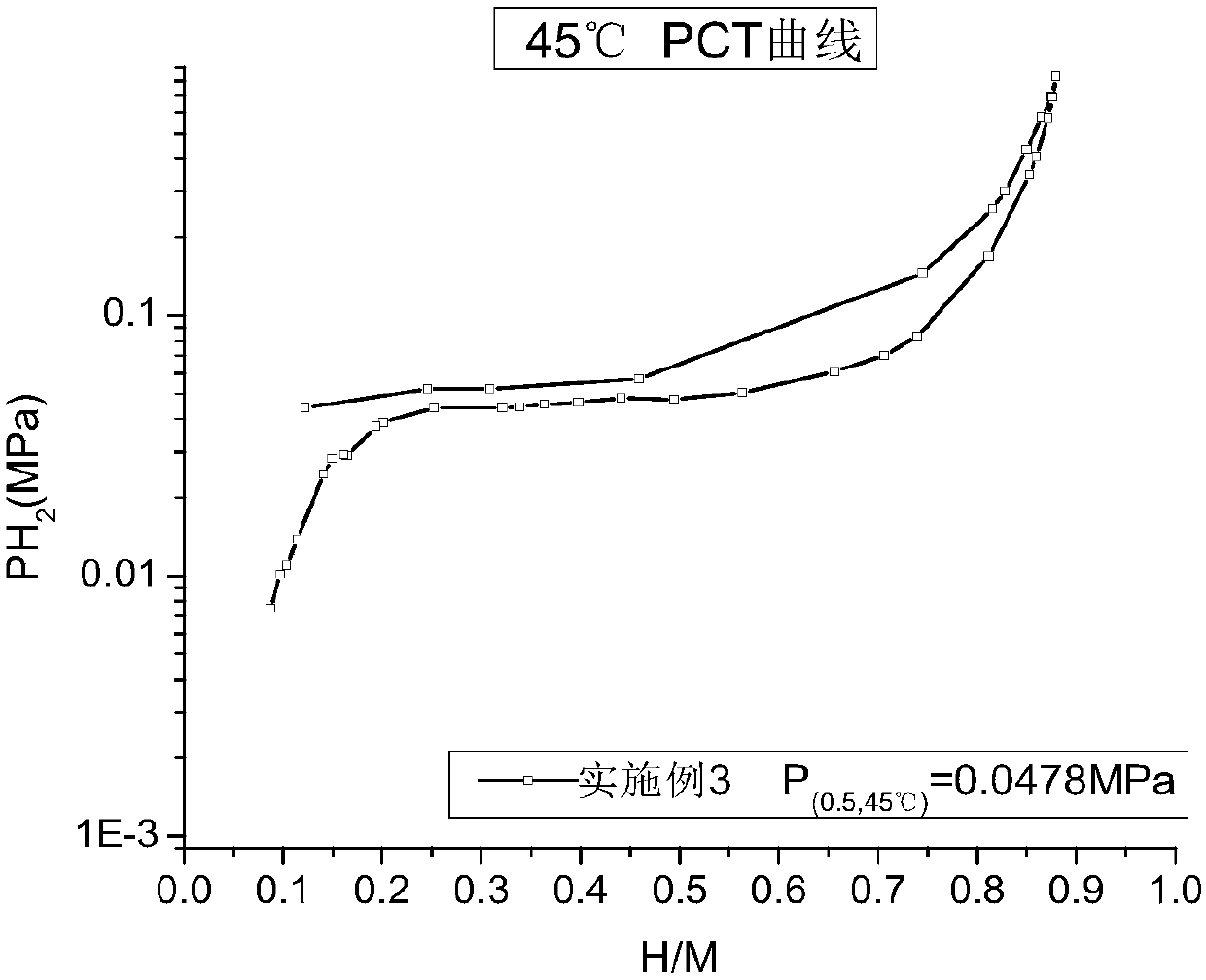

Embodiment 3

[0022] According to the structural formula La 0.740 Ce 0.250 Zr 0.010 Ni 4.620 mn 0.630 Al 0.200 Weigh the metal raw materials La, Ce, Zr, Ni, Mn, Al, put them in the crucible of the induction melting furnace, vacuumize (20Pa) and fill it with argon gas. The pressure in the furnace is 0.5MPa. Smelting for 3 hours to obtain a metal smelting solution; pouring the metal smelting solution into a water-cooled ingot mold and cooling to obtain an alloy ingot. Place the alloy ingot in a horizontal heat treatment furnace, vacuumize (20Pa) and fill it with protective gas argon, the pressure in the furnace is 0.05MPa, anneal at 1000°C for 15h, and obtain AB after crushing 5 Hydrogen storage alloys for Ni-MH batteries.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com