Automatic vulcanization shoe foxing strip attaching method

A technology for vulcanizing shoes and fences, applied in footwear, machines for connecting welts, clothing, etc., can solve the problems of low production efficiency, large changes in extrusion force, low adhesion quality, etc., and achieves high production efficiency, Small change in extrusion force and good adhesion quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0034] The method for automatically attaching vulcanized shoe surrounds provided in this embodiment comprises the following steps:

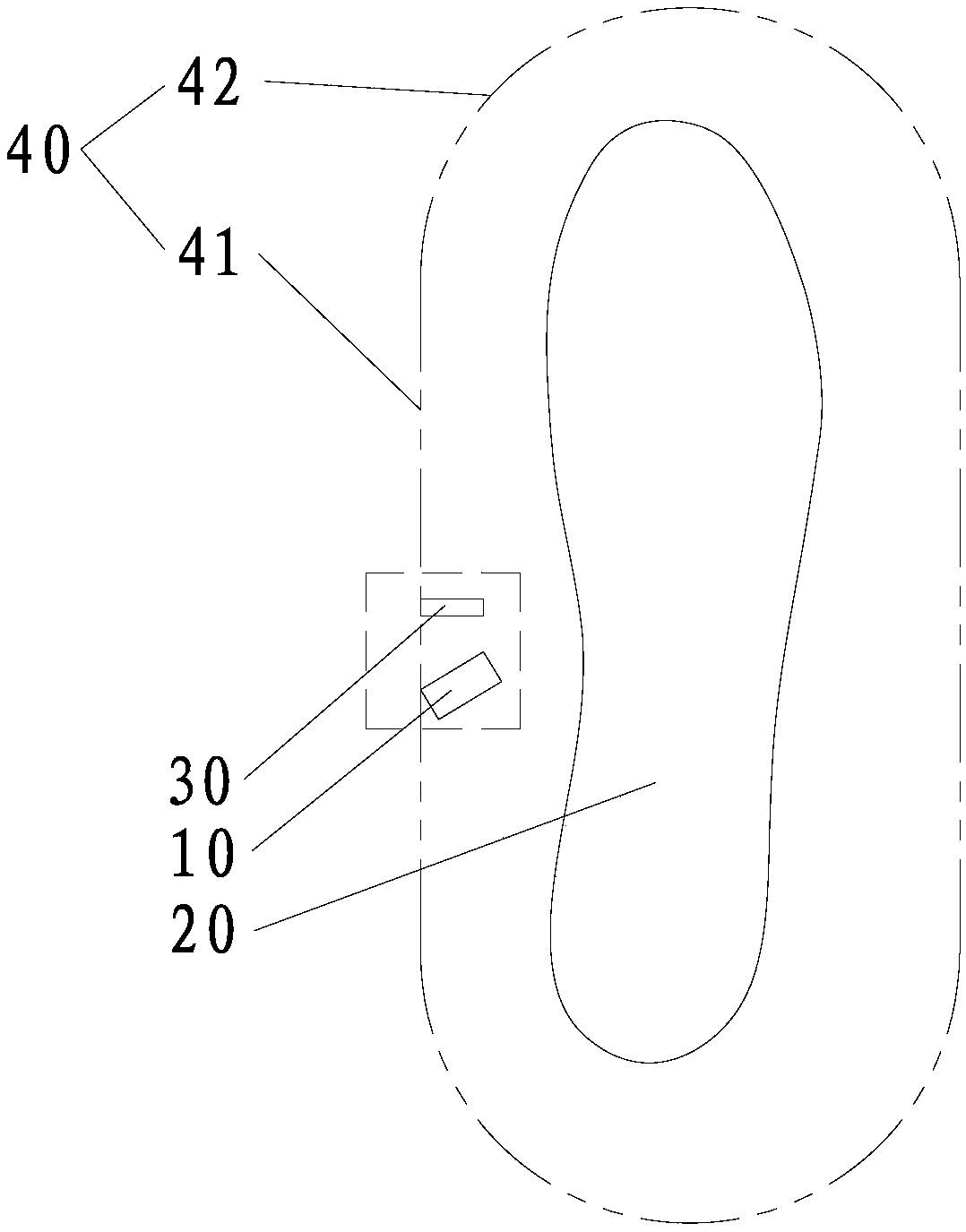

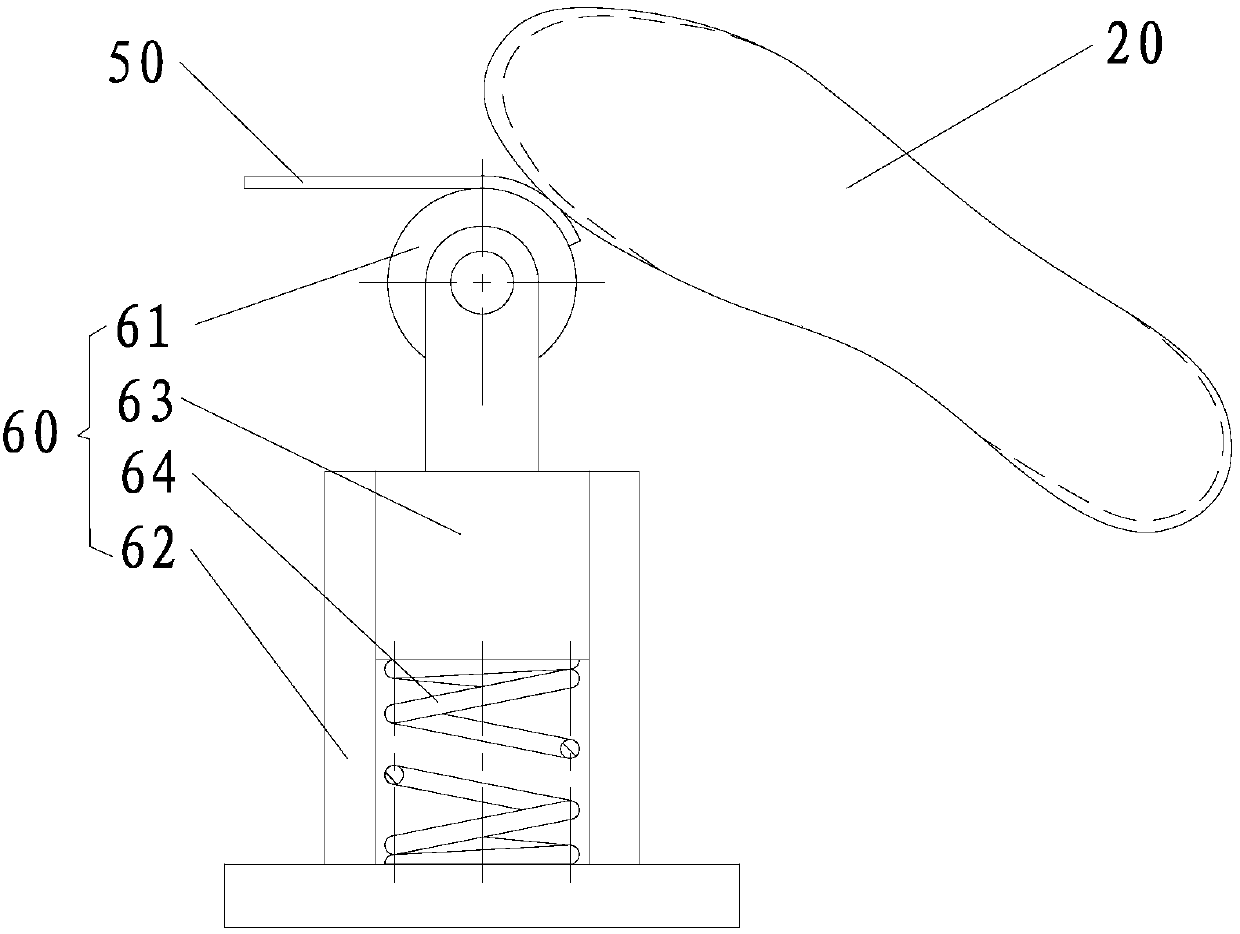

[0035] S1, pre-preparation, place the semi-finished vulcanized shoe to be attached to the fence in the scanning device, wherein the lens of the industrial camera of the scanning device faces the semi-finished vulcanized shoe. Preferably, in this embodiment, the sole of the semi-finished vulcanized shoe is placed facing up or down, and the scanning device has a line laser. When the semi-finished vulcanized shoe is placed facing upward, the line laser is located on the sole When the sole of the vulcanized shoe semi-finished product is placed face down, the inline laser is located above the side of the sole. Of course, the laser emission direction of the inline laser should be towards the handover position between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com