Thermocoagulation scalpel

A scalpel and scalpel handle technology, which is applied in the direction of surgery, surgical instrument parts, heating surgical instruments, etc., can solve the problems of insufficient temperature control compensation, cross infection, and short service life, so as to avoid burns and prevent crossover Effect of infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

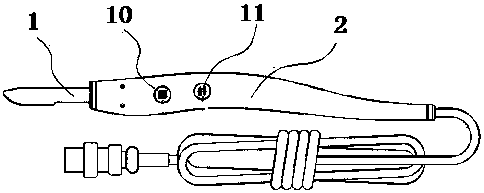

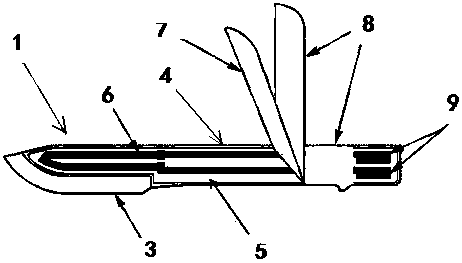

[0018] according to Figure 1-2 Shown, a kind of thermocoagulation scalpel, it is made up of scalpel blade 1 and scalpel handle 2, and described scalpel blade 1 and scalpel handle 2 form an integral structure, and scalpel blade 1 is sheet shape, and its front end side is provided with The knife edge 3 is provided with a knife body 4 at the peripheral connection of the knife edge 3. The knife body 4 is in the shape of a multi-layer sheet, and the base layer of the knife body is an insulating base layer 5. 7 and Teflon coating 8, an electrode 9 is provided at the rear of the knife body 4, the electrode 9 is inserted into the front end of the scalpel handle 2, and is in an overall fixed connection state, and an external heater is attached to the outside of the surgical blade And an external temperature sensor, the external heater is a heating circuit; the heating element 6 is a loop-shaped loop heating belt, and the loop heating belt is annular.

[0019] The heating circuit is l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com